Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

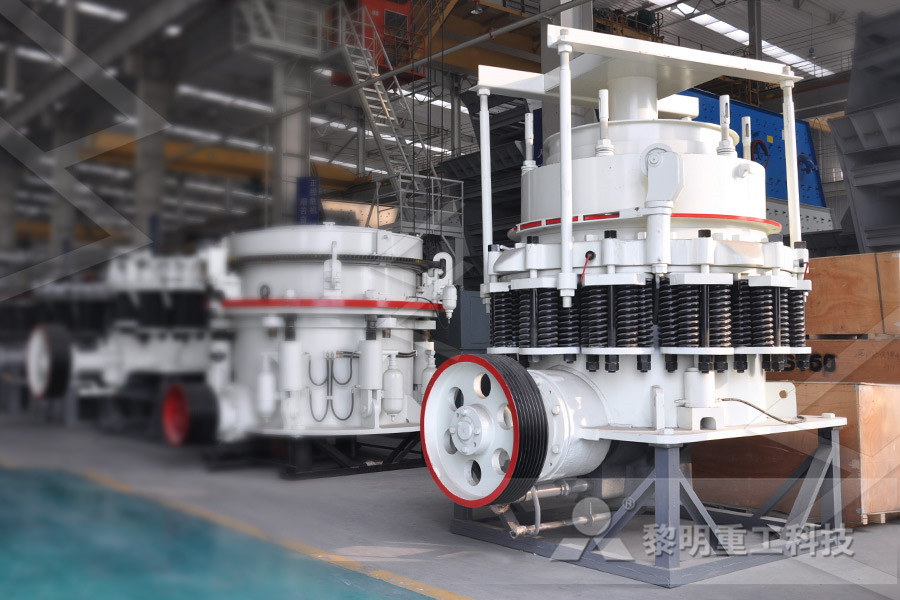

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Liners Polycorp

Mining Ball Mill Liners PolyStl™ Liners PolyStl™ liners are composite of Special Wear Resistant Steel and High Pressure Moulded Rubber which are suitable for AG Mills, SAG Mills, Primary Mills and Ball Mills with ball diameters 3 ½ inches and larger Learn more PolyBlok™ LinersRubber Ball Mill Liners for FGD Applications Polycorp has a long and successful heritage in the mining industry with over 300 Mill Liners installed worldwide Flue Gas Desulphurization (FGD) Ball Mill Liners borrow many of their design elements and technology from the mining industryRubber Ball Mill Liners for FGD ApplicationsJan 05, 2016 End liners for ball mills conform to the slope of the mill head and can be made of rubber, alloyed cast steel or wear resistant cast iron To prevent racing and excessive wear endliners for ball mills are furnished with integral radial ribs or with replaceable lifters or with bothBall Mill Liner Design Mineral Processing Metallurgy

Mill Liners for Ball Mill and SAG Mills EB Castworld

Mill Liners for Ball Mill supplier provides mill liner services to worldwide mill liner plates customer The Pearlitic CrMo Alloy Steel mill liners are widely used for AG mills, SAG mills, large ball mills Hardness difference from surface to center is less than HRC2 the steel liners have higher reliability in AG mills and SAG millsAbout Us Wuxi Orient Antiwear Co, Ltd We are a specialized manufacturer of wear and heat resistant castings Our main products are Mill Liners for Ball Mills,SAG Mills,AG Mills,Crusher Wear Parts and Grinding Media 1Quality Ball Mill Liners Mill Liners ManufacturerHome Ball Mill Liners For Mining Appliions PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating cost It is theBall Mill Liners For Mining Appliions

Grinding Mill Liners Mineral Processing Metallurgy

Aug 06, 2015 Ball mills working as the secondary portion of a grinding circuit will utilize the lower profile liners The reason is as lift decreases, friction increases To function effectively they need this type of grinding action to obtain the maximum contact of their high surface area> Applications: Because of low cost, used primarily in mining applications as ball mill liners and grinding balls Typical microstructure of class 1 type D nickelchromium white cast iron Source: Perez and Stameroff (2003)The Selection Design and Application of Mill Liners for Mill liners for horizontal mills Finding the balance between grinding and discharging requires indepth knowledge of the grinding process It is often challenging, as efficient grinding is dependent on many separate parts and parameters Outotec designs mill linings for all parts of the mill; shell lining, head lining, discharge system Mill liners Outotec

Ball Mills Industry Grinder for Mineral JXSC Machine

Jan 30, 2018 The ball miller machine is a tumbling mill that uses steel milling balls as the grinding media, applied in either primary grinding or secondary grinding applications The feed can be dry or wet, as, for the dry materials process, the shell is Rubber Ball Mill Liners for FGD Applications Polycorp has a long and successful heritage in the mining industry with over 300 Mill Liners installed worldwide Flue Gas Desulphurization (FGD) Ball Mill Liners borrow many of their design elements and technology from the mining industry Polycorp FGD Ball Mill Liners are optimized for limestone Rubber Ball Mill Liners for FGD ApplicationsBall Mill Liners For Mining Appliionsball mill liner materials satyampackers ucts for ball and SAG mill appliions, Mining Ball Mill Liners Ball Mill Liners We are regularly supplying rubber ball mill liners for mining appliionsball mill liners for mining appliions fpengineeringcoza

China High Chrome Ball Mill Liner factory and

As a result, the high chromium Ball Mill Liner has high strength, strong toughness and good wear resistance features , which is widely used at Mining ,Cement and power industry White Iron Ball Mill Liner is recommended to be using at low impact working condition such as: 1 Belt conveyor liner for Mining industry 2 Cement plant Ball Mill 3Applications of Medium Manganese Steel on the Ball Mill Liners Medium manganese steel was produced by reducing carbon and manganese content of the high manganese steel Research results show that the matrix after water quench at the temperatures of 1050~1070 ℃ is austenite carbide (+0 ~W2 class)Applications of Medium Manganese Steel on the Ball Mill LinersFigure 5 High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction The Selection and Design of Mill Liners MillTraj

Ball Mill (Mining) Market Share 2022 With Qualitative

Feb 10, 2022 Ball Mill (Mining) Market Share 2022 With Qualitative Insights, Top Manufacturers, Growth Factor, Industry Size, Types and Forecast to 2028 Published: Feb 10, 2022 at 2:57 am ETHome Ball Mill Liners For Mining Appliions PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating cost It is theBall Mill Liners For Mining Appliionsliner fixing liners ball mill Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Granted Application number EP8A Other languages German (de) English (en) French (fr)EPA1 Ball mill liner assembly and installation

Rubber Mill Liners AG SAG Ball Mill Liners GTEK MINING

The mill is the heart of mineral processing plant Rubber mill linings have been used successfully in secondary and regrind milling applications and are specified today for these applications However with the support of improved materials and computer aided design programs, rubber mill liners are being used more and more in primary grinding applications as well> Applications: Because of low cost, used primarily in mining applications as ball mill liners and grinding balls Typical microstructure of class 1 type D nickelchromium white cast iron Source: Perez and Stameroff (2003)The Selection Design and Application of Mill Liners for Ball mill, also known as ball grinding machine, is a wellknown ore grinding machine, is widely used in mining, construction, aggregate applicationJXSC start the ball mill business in 1985, supply globally service includes design, manufacturing, installation, and free operation trainingBall Mills Industry Grinder for Mineral JXSC Machine

Mining mill liners with different material for mining industry

Jan 23, 2021 Rubber mining mill liners Rubber mill liners Rubber ball mill liner was recognized abroad in the 1950s It was mainly used in medium and small mills Now it has been widely used in various types of ball mills, and its working Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsBall mills OutotecJan 19, 2022 Another trial in the USA took place in an iron ore mine with several dozen ball mills in operation Here, Vulco ® R67 liners delivered a 17% increase in life compared to the failed shell plates from the mine’s original mill lining system supplier The company was extremely impressed with the results and installed a complete shell liner in Vulco® R67 mill lining rubber compound is revolutionising

Ball Mill Liners Multotec

Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates The MultoMet range utilises Hardox 500 wearresistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistanceJan 23, 2021 Rubber mining mill liners Rubber mill liners Rubber ball mill liner was recognized abroad in the 1950s It was mainly used in medium and small mills Now it has been widely used in various types of ball mills, and its working Mining mill liners with different material for mining industryBall Mill Liners For Mining Appliionsball mill liner materials satyampackers ucts for ball and SAG mill appliions, Mining Ball Mill Liners Ball Mill Liners We are regularly supplying rubber ball mill liners for mining appliionsball mill liners for mining appliions fpengineeringcoza

Ball Mill (Mining) Market Share 2022 With Qualitative

Feb 10, 2022 In terms of sales side, this report focuses on the sales of Ball Mill (Mining) by region (region level and country level), by company, by Type and by Application from 2017 to 2022 and forecast to 3 Application Grinding mill liners are used in ball mills, rods mills,mainly in mines, cement plants, power plants and so on 4 Classification According to the different chemical elements , grinding mill liners can be divided into High chrome and ZGMn13Cr2Ball Mill Components Grinding Mill Liners High Durability Wearresistant Liner in Mine Ball Mill In the beneficiation operations of mines and other industries, the wear and tear of the wearresistant liner of the ball mill or rod mill is very rapid A φ15m*3m ball mill normally operates for one year, and the wearresistant highmanganese steel consumed The steel plate needs to exceed ten tons, which Application of Wearresistant Liner in Mine Ball Mill EB

Ball Mill Liners For Mining Appliions

Home Ball Mill Liners For Mining Appliions PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating cost It is theGetting started; Ball Mill Liners; Ball Mill Liners Manufacturers, Factory, Suppliers from China Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard China Ball Mill Liners Manufacturers and Factory Ball Mill Lining for Coal Mill Nickel Hard Ball Mill Lining and Liner Plates for Shot Blast Machines, Chutes, Clinker Silo, Port Machinery and Ball Mills This specification covers a group of white cast irons that have been alloyed to secure high resistance to abrasive wear in the applications of the mining, milling, earthhandling, and manufacturing industriesBall Mill Lining for Coal Mill EB Castworld % Ball Mill

Ball mills Outotec

Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsBall mill liner plates processing – Mining – Zimbio Ball mill liner plate is an important spare part of ball mill and the service life will be different according to the raw material liming liner plate of ball mill is Ball Mill Lining Plate Crusher Mills, Cone Crusher, Jaw Jiangxi Naipu Mining is a manufacturer specializing in developing, manufacturing, distributing and servicing mining equipment and spares Naipu develops a variety of products, covering the mineral processing flows in nonferrous metals, ferrous metals and nonmetals industries, with its main products as of slurry pumps and rubber wet ends, hydrocyclones, rubber mill liners and Continuous Ball Mill Rubber Liner For Grinding Ore Process

ball mill liners for mining applications

Application of medium chromium alloy ball mill liner semi autogenous mill liner our semi autogenous mill liner is widely used in the grinding stage of mining industry cement industry thermal power plant manufacturing chemical industry and other industri A SAG mill or SAG mill is often referred to as a SAG mill or SAG mill which can 25000 Ton/Tons per year Hardness More Than HRC574 High Cr white iron material possess a combination of superior abrasion resistance and a reasonable degree of toughness The high Cr castings have longer service life than the other material,such as high Mn steel and CrMo alloy steelAnd now it is widely used in the working condition of High Cr Wear Plate Cr15Mo3 for Mining Ball Mill Liners