Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

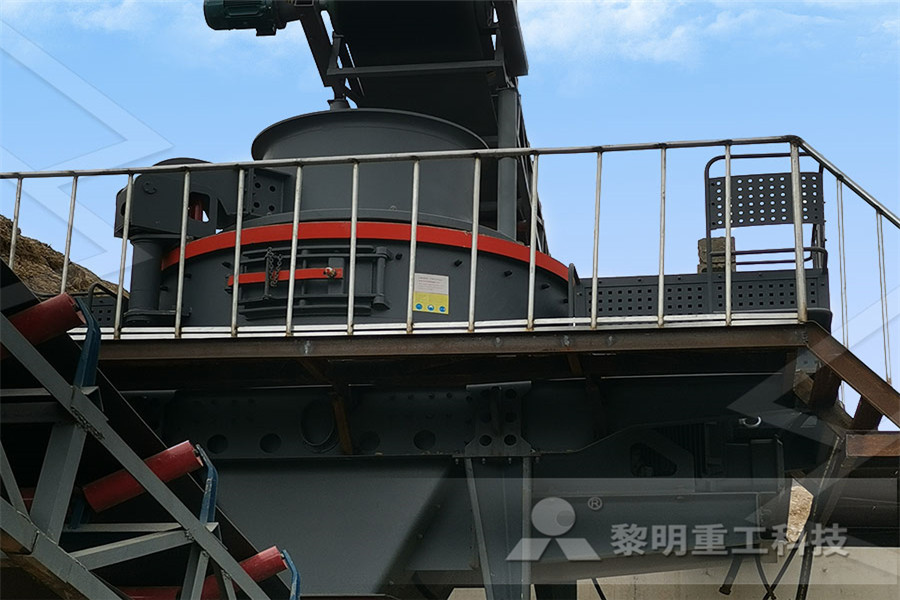

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cement mill Wikipedia

The emergence of Portland cement in the 1840s made grinding considerably more difficult, because the clinker produced by the kiln is often as hard as the millstone material Because of this, cement continued to be ground very coarsely (typically 20% over 100 μm particle diameter) until better grinding technology became availableJan 18, 2022 Savannah Cement wants to raise $350 million (Sh397 billion) via a bond on the London Stock Exchange (LSE) to build a clinker production plant The firm has been relying on imported clinker a Savannah Cement to raise Sh40b on London bourse for Higher the AM, lighter the color of clinker (cement) Normal range of SM is 125 MgO is commonly present in raw meal Some of the MgO (2%) is accommodated into the clinker mineral structure, while as extra MgO forms a crystal called periclase and causes mortar expansion MgO up to 4 % is found common in clinkerClinkerization Cement Plant Optimization

Cement kiln Wikipedia

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill);; heating the rawmix to sintering temperature (up to 1450 °C) in a cement kiln;; grinding the resulting clinker to make cement (see Cement mill); In the second stage, the rawmix is fed into the kiln and gradually heated by contact with SPECIALITY OF PRODUCTS SERVICE Ordinary Portland Cement (OPC) Our Gray Ordinary Portland Cement is a highquality, costeffective building material mainly composed of clinker that meets all applicable chemical and physical requirements and is widely used in all construction segments: residential, commercial, industrial, and public infrastructureChettinad cement Chettinad Group of CompaniesCement is a capex Heavy Business The ROAs of a cement plant is close to 1 So a Cement plant with 5000 Crores of Capex can typically do a turnover of 5000 Crores only Hence it is important, that not only does the company set up a plant in the best market (which offers best prices), it should also ensure that cost of setting up the plant is Understanding How The Indian Cement Industry Works

Cement Additives Sika

Clinker is often replaced with supplementary cementitious materials () such as granulated blast furnace slag, natural pozzolanes and fly ash in order to reduce CO 2 emissions and material cost However, may counteract strength development, powder flowability, mortar workability and durability, which are critical for cement qualityJan 31, 2022 The grade shows the minimum Compressive strength (N/mm2 or MPa) attainable by the cement after 28 days of setting The standard grades for Odinary Portland Cement (OPC) is Grade 43 and Grade 53 which are obtained by grinding and mixing OPC Clinker alongside little amount of Gypsum Most Nigerian cement brands meet up with the grading requirementCost of Cement per Bag in Nigeria Today (2022) – Beta PricesThe electrical energy consumed in the cement production is approximately 110 kWh/tonne 30% of the electrical energy is used for raw material crushing and grinding while around 40% of this energy is consumed for grinding clinker to cement powderCement Production an overview ScienceDirect Topics

Fujairah Cements industries located at Dibba town of

The plant is located at Dibba town of Fujairah Emirate It was supplied and erected by M/s Voest Alpine, Austria on a turnkey basis with a capacity of 500,000 MT of clinker with one cement grinding mill of 800,000 tons per annumCLINKER Lake Cement is the newest entrant in Tanzania's cement sector We leverage bestinclass technologies and extensive THE PLANT Tanzania's first cement plant to have 10 MW captive power plant; ensuring not only uninterrupted production import cost for Tanzania, but also keeps our carbon footprint in checkLake Cement Brochure Nyati CementCement is made by grinding clinker—the main energy intensive ingredient—to a fine powder Producers know that replacing some of the clinker in portland cement with ground limestone offers benefits, the most important being that it reduces the embodied CO2 of the cementPortlandLimestone Cement

Birla Shakti

Cement Production Process CLINKER GRINDING AND CEMENT PACKING Roller press with ball mill is used to grind the clinker 35 to 4% Gypsum is added to make OPC To make PPC, up to 35 % fly ash is added to the clinker in addition to Gypsum Three grades of cement (OPC 43, 53 and PPC) are manufactured and stored in silosJan 05, 2022 Attock Cement Pakistan Limited was established in 1981 with an initial capital outlay of PKR 15 billion including a foreign exchange component of USD 45 million The company started commercial production in 1988 with a plant capacity of 2,000 tons per day of clinker (approx 06 million tons annually)Attock Cement’s 20 MW Solar Power Plant Has Started to Aug 20, 2015 The result is called clinker, which are rounded nodules between 1mm and 25mm across The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement The powdered cement is then mixed with water and aggregates to form concrete that is used in constructionThe Cement Manufacturing Process Advancing Mining

Cement Types Portland Cement Association

What are the differences in these cement types and how are they tested, produced, and identified in practice? In the most general sense, portland cement is produced by heating sources of lime, iron, silica, and alumina to clinkering temperature (2,500 to 2,800 degrees Fahrenheit) in a rotating kiln, then grinding the clinker to a fine powderJan 28, 2022 Czech Republic: The high prices of European Union (EU) Emissions Trading Scheme (ETS) emission allowances, more than Euro84/t of CO 2 emitted in the week to 28 January 2022, are likely to make cement production more expensive Manufacturers are currently unclear how much prices will have to rise but stated that they could no longer absorb the rising Czech producers under pressure from EU ETS prices Cement Jan 05, 2022 President Robert Mugabe has opened PPC’s US$85mn cement grinding plant at Msasa in Harare Dangote ends Nigeria’s Cement importation and now In its 2016 full year audited results presented on the floor of the Nigerian Stock Exchange in Lagos yesterday, Dangote Cement sold 86mn metric tons of cement outside Nigeria, which is 54 per cent Topcon improves efficiency at Cotonou Cadjehoun Airport

Cement Types, Composition, Uses and Advantages of

Apr 04, 2018 Nanocement improves the technical quality of the Portland cement, reduces cost of production due to the use of 70 wt% mineral additives, 12–2 times reduction of the fuel cost, and 23 times reduction of emission of NO x, SO 2, and CO 2 per tonne of cement Nanocement has very high performance; for instance, the deflection strength of Dec 07, 2015 The company's production facilities are spread across eleven integrated plants, one white cement plant, twelve grinding units, and five terminals — four in India and one in Sri Lanka Most of the plants have ISO 9001, ISO 14001 and OHSAS 18001 certificationPROJECT ON ULTRATECH CEMENT SlideShareFrom 2015 to 2020, the global clinkertocement ratio is estimated to have increased at an average of 16% per year, reaching an estimated 072 in 2020; this rise was the main reason for the increase in direct CO 2 intensity of cement production over the periodCement – Analysis IEA

CO2 credits could account for 12 – 15% of EU cement

Dec 16, 2021 Europe: Cembureau, the European cement association, has calculated that if the European Union (UN) emissions trading scheme (ETS) CO 2 cost reaches Euro90/t then this could represent 12 15% of the production costs of cement producers The association made its calculation for an average cement plant in the region using data from Ecorys, WIFO, the The surplus clinker from Kymore would be supplied to a new grinding unit to be set up in Uttar Pradesh and the balance to Sindri Works, where the grinding, packing and loading capacity was under expansion from 03 MTPA to 06 MTPA Operation of the Cement plant unit at BandraKurla Complex was expandedACC History ACC Information The Economic TimesJan 31, 2022 President Robert Mugabe has opened PPC’s US$85mn cement grinding plant at Msasa in Harare Dangote ends Nigeria’s Cement importation and now In its 2016 full year audited results presented on the floor of the Nigerian Stock Exchange in Lagos yesterday, Dangote Cement sold 86mn metric tons of cement outside Nigeria, which is 54 per cent CHRYSO plasticiser utilised for Musina bridge project

Cement – Analysis IEA

From 2015 to 2020, the global clinkertocement ratio is estimated to have increased at an average of 16% per year, reaching an estimated 072 in 2020; this rise was the main reason for the increase in direct CO 2 intensity of cement production over the periodDec 16, 2021 Europe: Cembureau, the European cement association, has calculated that if the European Union (UN) emissions trading scheme (ETS) CO 2 cost reaches Euro90/t then this could represent 12 15% of the production costs of cement producers The association made its calculation for an average cement plant in the region using data from Ecorys, WIFO, the CO2 credits could account for 12 – 15% of EU cement The surplus clinker from Kymore would be supplied to a new grinding unit to be set up in Uttar Pradesh and the balance to Sindri Works, where the grinding, packing and loading capacity was under expansion from 03 MTPA to 06 MTPA Operation of the Cement plant unit at BandraKurla Complex was expandedACC History ACC Information The Economic Times

CHRYSO plasticiser utilised for Musina bridge project

Jan 31, 2022 President Robert Mugabe has opened PPC’s US$85mn cement grinding plant at Msasa in Harare Dangote ends Nigeria’s Cement importation and now In its 2016 full year audited results presented on the floor of the Nigerian Stock Exchange in Lagos yesterday, Dangote Cement sold 86mn metric tons of cement outside Nigeria, which is 54 per cent Jan 20, 2022 FGR says by adding low dosages of its PureGRAPHenhanced cement additives to the final grinding phase of cement production, up to 20% lower clinker factor cement production is made possible The purpose of the fiveyear collaboration agreement is to “facilitate the exchange of knowledge” through research and development work, the company ASX Green Energy stocks: First Graphene looks to develop BURNPUR CEMENT LIMITED is one of the most reputed and largest integrated cement companies in eastern India with two units at Asansol, West Bengal and Patratu, Jharkhand (033) 2262 3167; cs@burnpurcement; 7/1 Anandilal Poddar Sarani (Russel Street) 5th floor, Flat No 5B, Kanchana Building, Kolkata burnpurcement

Analysis and Optimization of Grinding Performance of

Jan 23, 2022 Mineral crushing is highly energy consuming, accounting for about 35–50% of the total cost and 18% of the global electrical energy consumption [1,2]Therefore, energyefficient grinding technologies have become the main focus of the industry, especially in the cement industry with largescale plantsDec 17, 2020 The grinding capacity of these plants stand enhanced to 25 MTPA and 325 MTPA, respectively In 2018, Ambuja Cement had invested Rs 139 million (US$ 21486 million) to set up a 17 MTPA greenfield clinker plant in Marwar Mundwa, Rajasthan, which was expected to be operational in the second half of FY20 However, due to the pandemic, it has Indian Cement Industry Report Cement Sector Research SF is a byproduct from silicon alloy production in electric arc furnaces SF is an ultrafine powder approximately 100× finer than cement grains, and it is almost pure silicon dioxide (SiO 2)The addition of SF to concrete greatly decreases the permeability and diffusion coefficient of the concrete compared with those of plain portland cement concreteSupplementary Cementitious Material an overview

Risk Assessment in Cement Manufacturing Process

quality of product, the cost should be minimize, improving delivery of product, reducing wastages cement plant health and safety environment created to 8 Grinding clinker with gypsum and fly ash 9 Packing in packers 10 Dispatch products Methods : 1 Risk identificationFeb 02, 2022 Savannah Cement to raise Sh40b on London bourse for clinker plant Why cement makers shun local clinker for expensive imports Bamburi Cement to cut electricity costs with two solar Sep 22, 2020 The predominant source of GHG emissions in cement production is the production of clinker at the kilning stage, although grinding, sorting of raw materials and packaging of cement bags also have a Environmental impacts and decarbonization strategies in

fairportcouk – fairportcouk

Cement Fairport has provided materials handling facilities at almost all of the United Kingdom’s cement works Systems delivered include bulk raw materials intake and processing, including alternative fuels, through to clinker grinding, and additive Obajana plant in Kogi state, Nigeria, is the largest in Africa with 1325Mta of capacity across four lines; Ibese plant in Ogun State has four cement lines with a combined installed capacity of Dangote Cement Continues To Deepen Debt Market Activities