Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

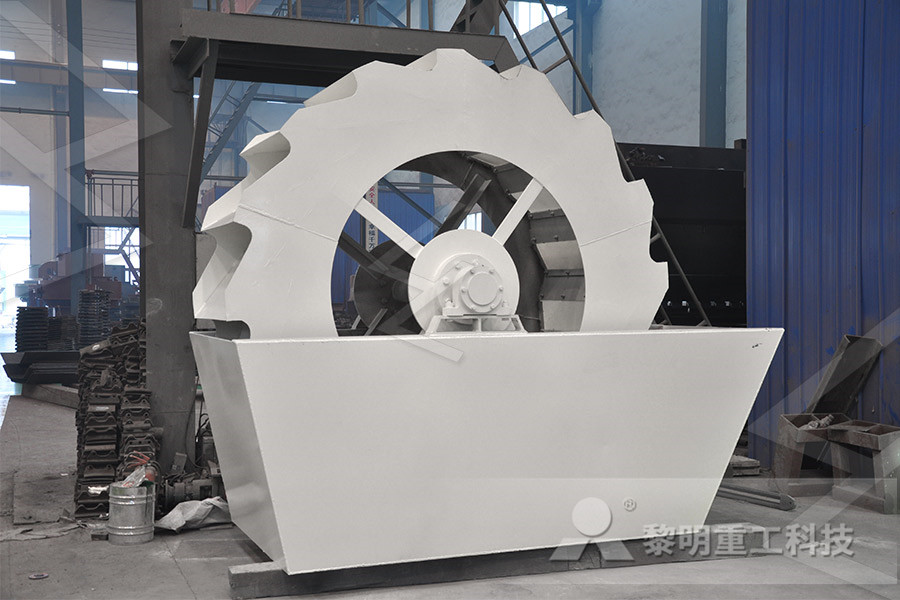

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

A simplified process flow chart for a steelmaking process

(SSAB, 2005) Figure 5 shows a simplified process chart for an integrated steelmaking process with a coke oven and blast furnace An alternative route for the production of iron from iron ore is 3 PROCESS: In the Blast Furnaces (BF) liquid iron (popularly termed as ‘Hot Metal’) is produced by the process of reduction at high temperature from raw materials like iron ore, base mix, sinter, pellet, coke, fluxes (limestone, quartzite, Dolomite Mnore), etc also pre heated air blast / O 2 In blast furnace the process isOBJECTIVE: SCOPE: 3 PROCESSJun 21, 2018 Blast furnace process In the blast furnace, the iron ore reacts with the carbon contained in the coke to form grey or white pig iron 1 Combustion process 2 Boudouard reaction 3 Preheating 4 Indirect reduction zone 5 Direct reduction zone 6 Carburizing zone 7 Melting zone 8 Tapping zone Combustion processBlast furnace process tecscience

Blast Furnace Process Steel Museum

Blast Furnace Process A blast furnace is a steel cylinder lined with refractory It operates continuously until the lining wears out, which takes many years to occur The term blast furnace comes from the blast of hot air that is blown into the lower part of the furnace at between 1400º to 2100ºF Molten iron is produced in a blast furnace Jul 12, 2019 Blast Furnace and Process Description 3D Model The preheated air (1000–1300 °C) is blown through it The oxygen of the blast burns coke to CO and several combustion zones, one in front of each tuyere, exist in the tuyere zone The hearth zone is the bottommost region, where the hot metal and slag are storedBlast Furnace and Process Description Chemical The process takes a lot of time; Blast furnace process requires a lot of energy consumption The process cannot be shut down Blast Furnace Application: The main application of the blast furnace is to smelt the iron from its ore and The pig iron formed during the process is used for the production of various grades of steelBlast Furnace: Definition, Construction or Parts, Working

Cement Manufacturing Process Flow Chart

Heated in a blast furnace with coke Hot air is blown from the bottom to provide oxygen Ore becomes Oxides combine Given below is a process description Read it and draw a flow chart representing the process described Rayon is a manmade fibre It is a reconstituted natural fibrecellulose Rayon is made by dissolving cellulose in a The figure shows a flowchart of the integrated manufacturing process for iron and steel using the blast furnace and basic oxygen furnace (denoted BF and BOF hereinafter, respectively), which is presently the most commonly used method (51% of world steel production)1A Manufacturing Process for Iron and SteelDec 08, 2020 Blast Furnace The current blast furnace is a giant steel shell built like a cylinder and packed with heatresistant bricks For the coke steel making process, iron ore, coke, and limestone are pumped into the furnace from the top and eventually sink straight to the bottom, becoming hotter as they go downIn the upper half of the furnace, cokeburning gas releases Steel Making Procedure StepByStep Guide

Cement Manufacturing Process Flow Chart

Heated in a blast furnace with coke Hot air is blown from the bottom to provide oxygen Ore becomes Oxides combine Given below is a process description Read it and draw a flow chart representing the process described Rayon is a manmade fibre It is a reconstituted natural fibrecellulose Rayon is made by dissolving cellulose in a Process Description RD Trends Blast furnaces are usually tall shafttype steel vessels, up to ten stories high, internally lined with refractory brick, and superimposed over a cruciblelike hearth The necessary charge to produce molten pig iron consists of ironbearing materials, coke, and flux The charge is introduced into the furnace at Blast Furnace Process Description HeatTreatConsortiumFlow chart of the charging algorithm indicate blast furnaces from the cooperation of the Research Center of suitable control of the blast furnace process and serve to Advanced Mechatronic Systems with a pig iron producer in verify the blast furnace loading model The decrease in the Czech Republic, the company Třinecké železárny 2020 Computer modelling of burden distribution in the blast

Extraction of Iron Metallurgy Blast Furnace and Reactions

A blast furnace is a gigantic, steel stack lined with refractory brick where the concentrated iron ore, coke, and limestone are dumped from the top, and a blast of hot air is blown into the bottom All the three ingredients are crushed into small round pieces and mixed and put on a hopper which controls the input12516 Steelmaking Process — Open Hearth Furnaces The open hearth furnace (OHF) is a shallow, refractorylined basin in which scrap and molten iron are melted and refined into steel Scrap is charged to the furnace through doors in the furnace front Hot metal from the blast furnace is added by pouring from a ladle through a trough positioned125 Iron And Steel Production US EPABlast furnace process (Figure 2) The blastfurnace is a shaft type furnace operating by the counterflow technique : the descending burden of sinter and coke, charged from the top of the furnace, is heated and reduced by the combustion gases ascending from the tuyere zone where a hot air blast is injected to burn C to COSteel Production Technology Metallurgy for Dummies

Steel Making Process Complete Overview with Flowchart

Nov 18, 2021 Steel Making Process The commercial processes for making steel are : (1) Bessemer process, (2) LD process, (3) Openhearth process, (4) Crucible process, (5) Electric process, (6) Duplex process The Bessemer, open hearth and electric process can be subdivided into (a) acid process and (b) basic process, according to the type of lining used in Nov 25 2012 flow chart of iron ore pellet plant process in india flow chart of iron ore pellet plant process Mill in India quarry plant in as packed spheres in the blast furnace allows air to flow between the »More detailedProcess Flow Diagram Of Iron Ore Mining And Benifeciation and New Guinea The process is almost same as pig iron production processes The only difference is that the ore contains more nickel The blast furnace products contain 210% of nickel A new approach is usage of electric arc furnaces to FERRONICKEL PRODUCTION AND OPERATION

Flowchart of iron and steelmaking processes [8] Download

A flow chart that illustrates the kinds of slag produced for each process of iron and steelmaking is shown in Figure 1 This paper critically examines utilization of steel slags for road Iron Ore Processing for the Blast Furnace to brief you if you want a more specific understanding of the iron ore mining process and detailed iron ore mining process flow chart please contact our customer service they will be detailed to you to explain the process and provide detailed Process Flow Diagram Of Iron Ore Processing PlantNov 12, 2012 blast furnace process flow chart – Grinding Mill China Iron Flow ChartBLAST FURNACE The iron was shaped into iron bars by undergoing a process of heating and » Free Online Chat Blast furnace – Wikipedia, the »More detailedflow chart of blast furnace complex Mining

Iron ore mining and dressing tecscience

Jun 21, 2018 The blast furnace process accounts for over 80 % of total steel production Therefore, the blast furnace process will be discussed in more detail in the following The flow chart shows the basic steps of how iron ore is used to produce semifinished products of steel The individual process steps are explained in more detail in the following process which is mostly carried out in a blast furnace, using coke as both a fuel and reducing agent The metallic iron produced by such a furnace contains a relatively high proportion of carbon (4%) and is passed to the steelmaking process as a liquid at approximately 1450C, called "hot metal" Refining: SteelmakingThe Making of Iron Steel(SSAB, 2005) Figure 5 shows a simplified process chart for an integrated steelmaking process with a coke oven and blast furnace An alternative route for the production of iron from iron ore is a A simplified process flow chart for a steelmaking process

Flow chart of the prediction model used in the BF

Download scientific diagram Flow chart of the prediction model used in the BF from publication: Radar Detectionbased Modeling in a Blast Furnace: a Prediction Model of Burden Surface Shape 3 PROCESS In the Blast Furnaces (BF) liquid iron (popularly termed as ‘Hot Metal’) is produced by the process of reduction at high temperature from raw materials like iron ore, base mix, sinter, coke, fluxes (limestone / quartzite), etc also air blast / RECOMMENDED GUIDELINE FOR IRON STEEL SECTOR Jan 01, 2010 Important properties of sinter for blast furnace process are reducibility, size and size distribution, cold and hot strength, and softening and melting behavior Typical sinter suitable for blast furnace process is from 15 to 25 mm, as is illustrated in Figure 1110 [22]Another important property is the disintegration of sinter in reduction, which occurs during the Blast Furnace Process an overview ScienceDirect Topics

BLAST FURNACE TECHNOLOGY

blast furnace technology 3 hot metal and pig iron produced by last b furnaces stand for 60% of all steel products which the world’s population consumes last urnace ironmaking is a traditional technology which has been steadily f bBlast Furnace Process A blast furnace is a steel cylinder lined with refractory It operates continuously until the lining wears out, which takes many years to occur The term blast furnace comes from the blast of hot air that is blown into the lower part of the furnace at between 1400º to 2100ºF Molten iron is produced in a blast furnace Blast Furnace Process Steel Museum blast furnace boilers/stoves receiving > 90% of total annual gas from blast furnace gas (40 CFR 637491) A process heater is an enclosed device with a controlled flame that has a primary purpose of indirectly transferring heat instead of generating steam Indirect process heaters include devices in which the combustion gasesNESHAP 5D 6J Boiler Flowchart

Cement Manufacturing Process Flow Chart

Heated in a blast furnace with coke Hot air is blown from the bottom to provide oxygen Ore becomes Oxides combine Given below is a process description Read it and draw a flow chart representing the process described Rayon is a manmade fibre It is a reconstituted natural fibrecellulose Rayon is made by dissolving cellulose in a Process Description RD Trends Blast furnaces are usually tall shafttype steel vessels, up to ten stories high, internally lined with refractory brick, and superimposed over a cruciblelike hearth The necessary charge to produce molten pig iron consists of ironbearing materials, coke, and flux The charge is introduced into the furnace at Blast Furnace Process Description HeatTreatConsortiumThe figure shows a flowchart of the integrated manufacturing process for iron and steel using the blast furnace and basic oxygen furnace (denoted BF and BOF hereinafter, respectively), which is presently the most commonly used method (51% of world steel production)1A Manufacturing Process for Iron and Steel

125 Iron And Steel Production US EPA

12516 Steelmaking Process — Open Hearth Furnaces The open hearth furnace (OHF) is a shallow, refractorylined basin in which scrap and molten iron are melted and refined into steel Scrap is charged to the furnace through doors in the furnace front Hot metal from the blast furnace is added by pouring from a ladle through a trough positionedThe process takes a lot of time; Blast furnace process requires a lot of energy consumption The process cannot be shut down Blast Furnace Application: The main application of the blast furnace is to smelt the iron from its ore and The pig iron formed during the process is used for the production of various grades of steelBlast Furnace: Definition, Construction or Parts, Working 3 PROCESS: In the Blast Furnaces (BF) liquid iron (popularly termed as ‘Hot Metal’) is produced by the process of reduction at high temperature from raw materials like iron ore, base mix, sinter, pellet, coke, fluxes (limestone, quartzite, Dolomite Mnore), etc also pre heated air blast / O 2 In blast furnace the process isOBJECTIVE: SCOPE: 3 PROCESS

Extraction of Iron Metallurgy Blast Furnace and Reactions

A blast furnace is a gigantic, steel stack lined with refractory brick where the concentrated iron ore, coke, and limestone are dumped from the top, and a blast of hot air is blown into the bottom All the three ingredients are crushed into small round pieces and mixed and put on a hopper which controls the input