Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

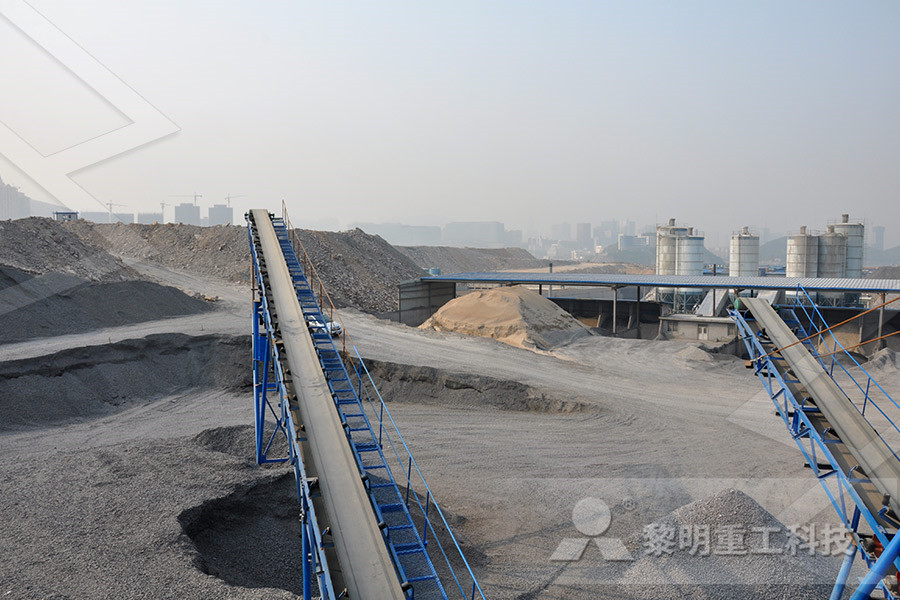

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Mechanical Milling an overview ScienceDirect Topics

Mechanical milling is used to change the properties of silver powders, including disintegration of particle aggregates, particle shape, and particle surface characteristics This process can be used for most types of silver powders with techniques such as ball milling, vibratory milling, or Feb 03, 2012 Mechanical milling has also been widely used for the synthesis of noncrystalline metals, alloys intermetallic compounds, ceramics, composites and nanocomposites amd it can be used for the production of various intermetallics and nanocomposites in situ, by milling metallic powders in reactive atmospheres[2022]Mechanical Milling: a Top Down Approach for the Synthesis Feb 03, 2012 The mechanical milling has been utilized for the synthesis of nanomaterials either by milling and post annealing or by mechanical activation and then applying some other process on these activated materialsMechanical Milling: a Top Down Approach for the

(PDF) "Mechanical Milling" ResearchGate

mechanical alloying, can be produced by ball milling In the 1970s, mechanical synthesis w as limited to the fabrication of super alloys How ever, it is used today to produce nanocrystallineOne of the more commonly used milling techniques is known as mechanical milling, which generally requires a highpowered motor rotating some type of milling surface Mechanical milling aims to reduce the particle sizes of material by physically breaking the structure of a material by overcoming the materials own interior bonding forcesMechanical Milling vs Jet Milling Fluid Energy Jan 01, 2001 The mechanism of mechanical alloying will be discussed in Section 5 and Section 6 briefly describes the different methods of characterizing the mechanically alloyed powders The temperature rise observed during milling of powders is discussed in Section 7Mechanical alloying and milling ScienceDirect

An AlLi Powder Alloy Prepared by Mechanical

This work involves the preparation and microstructural characterization of an AlLi alloy by high energy ball milling In order to obtain solid samples, the prepared powders were sintered An AlLi2% (in wt%) alloy was prepared from a weighted mixture of pure Al and AlLi5% chips and processed in a SPEX 8000M mill by 2 hoursMilling machine is another most important machine tool after the Lathe machine tool and drilling machine In this machine, a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly In today's article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add the Milling Machine: Definition, Parts Learn MechanicalCorpus ID: ; Mechanical milling of aluminum powder using planetary ball milling process @article{Ramezan2012MechanicalMO, title={Mechanical Figure 9 from Mechanical milling of aluminum powder using

(PDF) Mechanical Alloying and Milling ResearchGate

The high energy ball milling effect of the Al2O3 with varying contents, ie, 5, 10, and 15 wt%, on the mechanical properties, corrosion resistance, and An AlLi Powder Alloy Prepared by Mechanical Milling and Sintered Using High Frequency Induction Author: JM MendozaDuarte Subject: Microsc Microanal Proceedings, (2018), 24, An AlLi Powder Alloy Prepared by Mechanical Milling and Silica sand nanoparticles are widely used as filler, coating and reinforcer to increase materials strength and durability The objective of the research is to design a new technique of Mechanical Milling of Tronoh Silica Sand Nanoparticles

Texture formation in iron particles using mechanical

Sep 09, 2015 Crystallographically anisotropic platelet iron particles with a {001} texture and no preferred inplane orientation were successfully prepared using a conventional ball mill with The mechanical milling process is a popular technique used to produce micro and nanoparticles Therefore, it is very important to improve milling process efficiency and quality by Determining the effect of process parameters on particle Jun 28, 2009 Milling is an important process of manufacturing technology and basically it refers to the removal of metal from the work piece using a tool which has several cutting points and Milling Machine: Methods of Milling Milling Processes

for MANUAL MILLING MACHINES Department of

many other shapes The type of milling machine in the UCR Mechanical Engineering Machine Shop is a variable speed vertical spindle, kneemill with a swiveling head (also known as a crystals Article Regulating Mechanical Properties of Al/SiC by Utilizing Di erent Ball Milling Speeds Saud M Almotairy 1,* , Nabeel H Alharthi 2 and Hany S Abdo 1,3,* 1 Centre of Regulating Mechanical Properties of Al Utilizing Di erent In this paper, we report the results obtained from different phases of metal hydrides The synthesis and characterization of tantalum hydrides were obtained “in situ” during mechanical Synthesis of Tantalum Hydride Using Mechanical Milling and

Mechanical Properties of WCCo Alloys with Various Mixing

Title:Mechanical Properties of WCCo Alloys with Various Mixing and Milling Conditions using High Energy Ball Miller Volume: 10 Issue: 1 Author(s): JoonWoo Song, Rumman Md Corpus ID: Mechanical milling of aluminum powder using planetary ball milling process @article{Ramezan2012MechanicalMO, title={Mechanical milling of aluminum Figure 10 from Mechanical milling of aluminum powder using May 08, 2020 Any machine using utilises computerised systems for automating the cutting process Therefore, machines also include laser cutters, plasma cutters, press brakes, Milling a Complete Guide to Understand the Process

(PDF) Dynamic modelling of hardness changes of aluminium

Unloading ARTICLE INFO ABSTRACT Article history: In this research, the feasibility of using mathematical modelling in the ball milling Received 19 August 2016 process has been Mechanical milling and ultrasonic mechanical coating and armouring (UMCA) were used for depositing of TiN coatings on different substrates A powder and balls were placed in a vibration chamber The substrate can be placed in the chamber with the powder or it can be fixed to the top of the chamber During a mechanoactivation process, the Fabrication of TiN coatings using mechanical milling An AlLi Powder Alloy Prepared by Mechanical Milling and Sintered Using High Frequency Induction Author: JM MendozaDuarte Subject: Microsc Microanal Proceedings, (2018), 24, S1, 22542255, doi: 101017/S11753 Created Date: 222ZAn AlLi Powder Alloy Prepared by Mechanical Milling and

Highenergy mechanical milling of poly(methyl methacrylate

requisite to the use of mechanical alloying as a means of producing novel polymer blends Mechanical milling (involving one material) and mechanical alloying (involving two or more materials) generally refer to highenergy ballmilling techniques employed to process materials in the solid state [14]Milling machine is another most important machine tool after the Lathe machine tool and drilling machine In this machine, a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly In today's article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add the Milling Machine: Definition, Parts Learn Mechanicalcrystals Article Regulating Mechanical Properties of Al/SiC by Utilizing Di erent Ball Milling Speeds Saud M Almotairy 1,* , Nabeel H Alharthi 2 and Hany S Abdo 1,3,* 1 Centre of Excellence for Research in Engineering Materials, King Saud University, PO Box 800, Riyadh 11421, Saudi Arabia 2 Department of Mechanical Engineering, College of Engineering, King Regulating Mechanical Properties of Al Utilizing Di erent

Texture formation in iron particles using mechanical

Sep 09, 2015 Crystallographically anisotropic platelet iron particles with a {001} texture and no preferred inplane orientation were successfully prepared using a conventional ball mill with graphite (Gp) particles under air atmosphere This work provides the first example of the inducement of crystallographic orientation in a metal by dry mechanical millingSilica sand nanoparticles are widely used as filler, coating and reinforcer to increase materials strength and durability The objective of the research is to design a new technique of converting Tronoh silica sand to silica sand nanoparticles by using ingenious combination of milling process and heating mechanism Raw Tronoh silica sand was milled for 10 hours with heating process Mechanical Milling of Tronoh Silica Sand Nanoparticles Jun 28, 2009 Milling is an important process of manufacturing technology and basically it refers to the removal of metal from the work piece using a tool which has several cutting points and is rotating about its axis Thus each cutting point removes a little bit of the metal but since there are multiple such points and the tool is rotating at a fast speed, the overall removal is quite briskMilling Machine: Methods of Milling Milling Processes

Milling a Complete Guide to Understand the Process

May 08, 2020 Any machine using utilises computerised systems for automating the cutting process Therefore, machines also include laser cutters, plasma cutters, press brakes, etc So machining is a mix of these two terms, bringing us the answer to the question posed in the heading milling is a substractive fabrication method that uses automatic gear milling machine using proximity sensor Since pneumatic circuit plays a vital role in this device, it is very necessary to explain the working of this circuit Initially starting with air compresses, its function is to compress air from a low inlet pressure (usually atmospheric) to a higher pressure levelAUTOMATIC GEAR MILLING MACHINE USING PROXIMITY Sep 03, 2020 In this paper they have conducted experimental work on the vertical milling machine by using TUNGSTEN CARBIDE tool cutter and COPPER material was machined by milling process They considered speed, feed and depth of cut as input parameters for finding material removal rate, surface roughness by using RSM GA they analyzed the effect of Optimization of Machining Parameters of Surface IJERT

Ultra grain refining of iron using mechanical milling

Mechanical milling treatment of iron powder was applied as the technique to charge an extremely large strain into iron matrix Milling treatment using high energy vibration ball mill enable a significant work hardening of iron to Hv950 after a long time milling, whereas the maximum hardness achieved by conventional coldrolling process for bulk iron is small as Hv280When milling titanium alloy, the cutting temperature has a strong impact on the degree of tool wear and, in turn, tool life and the surface quality of the workpiece The distribution of the temperature field on a tool's rake face can be improved through the use of microtextures, which help to reduc Temperature Field of Tool Engaged Cutting Zone for Milling The carbonophosphate Na 3 FePO 4 CO 3 was synthesized by the mechanical ball milling method for the first time The composition of the obtained sample with a higher amount of Fe 2+ was Na 266 Fe 2+ 066 Fe 3+ 034 PO 4 CO 3 as confirmed by Mössbauer analysis, owing to the good airtight properties of this method The obtained samples in an organic electrolyte Cathode Properties of Na 3 FePO 4 CO 3 Prepared by the