Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

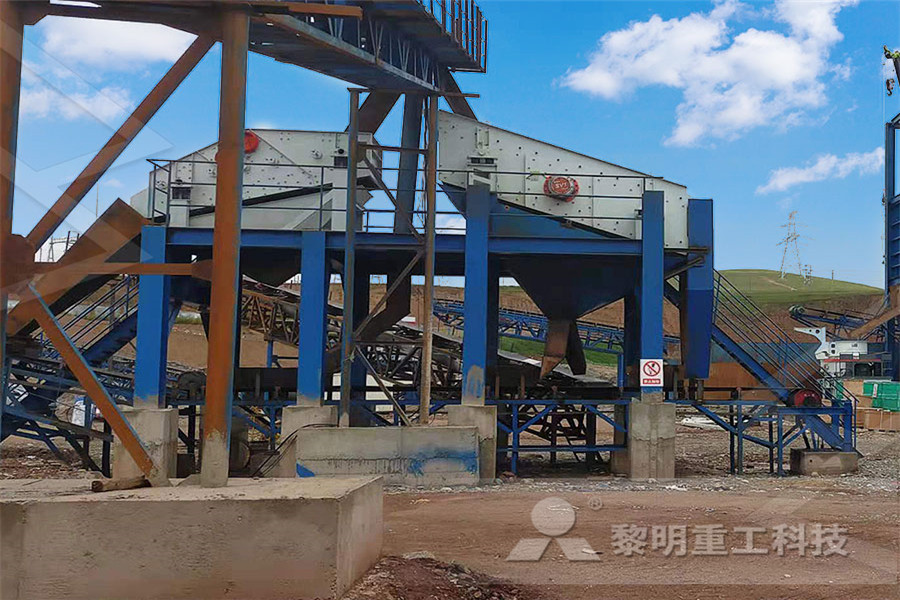

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

chemical crushing silver mining

Feb 05, 2022 SILVER CRUSHING PROCESSING COPPER ORE CRUSHING PROCESSING Being the largest mining machinery manufacturer In the east of China Expert of Machinery Production The main products include Crusher and Mineral Processing Machine News Event service Germany technology of KHM Group In the 2012, Silver mining process Silver is commonly extracted from ore by crushing, grinding, smelting or chemical leaching crushers have a very important role in silver ores mining, especially in silver ores’ crushing process The Jaw Crusher is commonly used as the primary crusher and Impact Crusher, Cone Crusher are used as secondary crusherSilver mining equipment, silver crushing and grinding Crushing is done in two phases followed by milling in the bar and ball mills The flotation process is conducted in the stages The first stage is the silvergoldlead flotation which is followed by the zincsilver flotation and pyrite flotation stages Each flotation stage consists of several stepsMineral Processing Silver

Chemical Processing 101: Crushing Howard Industries

Crushing is the process of reducing the size of materials so that they can be further processed In addition to being used in the chemical industry, industrial crushing equipment can be very useful in a variety of businesses These include, but are not limited to, waste and recycling, mining, food processing, construction, and coalthe complete mineral ore processing plant always includes crushing, grinding and beneficiation stages, and the beneficiation stage consists of different technology, mainly gravity separation, flotation, magnetic separation, chemical processing, etc prominer can customize the suitable technological process based on the mineral characteristics and Genera Processing Technology For Minerals Prominer Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) SIZE REDUCTION BY CRUSHING METHODS

Introduction to Mineral Processing Sepro Labs

Introduction to Mineral Processing Sepro LabsSilver crushing processing Silver is commonly extracted from ore by smelting or chemical leaching Silver mining is the resource extraction of silver by mining Silver ore beneficiation first choice is large capacity magnetic separation, followed by is electrostatic separation, and then reelection, and the minimum is flotationsilver ore crushing processSilver mining process Silver is commonly extracted from ore by crushing, grinding, smelting or chemical leaching crushers have a very important role in silver ores mining, especially in silver ores’ crushing process The Jaw Crusher is commonly used as the primary crusher and Impact Crusher, Cone Crusher are used as secondary crusherSilver mining equipment, silver crushing and grinding

Mineral Processing Silver

Mineral Processing The mined ore is crushed and milled before the flotation process to desired grain size Crushing is done in two phases followed by milling in the bar and ball mills The flotation process is conducted in the stages The first stage is the silvergoldlead flotation which is followed by the zincsilver flotation and pyrite May 24, 2016 The Silver Cobalt Extraction Flowsheet In this study, the silver occurs essentially as impure native silver together with argentite, cobaltite and other complex sulfides The flowsheet is based on a 400 ton per day concentrator with special emphasis on “recover your mineral as soon as free” CRUSHING Silver Cobalt OreSilver Cobalt Processing by Gravity and FlotationDec 13, 2012 crushing silver ore,mobile silver plant,used silver ore processing Silver properties A soft, white, lustrous transition metal, it has the highest electrical conductivity of any element and the highest thermal conductivity of any metalsilver mine process plant Mining

KHM Mining MachineryNO1 in ChinaKINGHONG MACHINE

SILVER CRUSHING PROCESSING COPPER ORE CRUSHING PROCESSING IRON ORE CRUSHING PROCESSING Chemical Agitation Tank Mixer >Concentrating Equipment Vacuum Pressure Filter available mineral processing technology, plant size, required equipment and periodMineral processing Wikipedia Copper Mining and Extraction Sulfide Or Crushing and grinding The ore from the mine contains about 2 At this stage of the process the chemical reactions Copper Mining Info The above flowsheet shows a basic copper mine process from mine to metal Then the ore is crushed and screened mineral processing also known as ore in a mineral why is ore crushed before any chemical process is attemptedwill involve the crushing and grinding (which is also known by a common name called To obtain the correct degree of liberation in mineral processing – ii To increase the specific surface area of the valuable minerals for in physical (or chemical) properties of the metal and gangue compound in the oreMineral dressing (= Orebeneficiation) kau

mineral processing metallurgy Britannica

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other The lithosphere consists of rocks, which contain minerals Minerals are natural compounds formed through geological processes A mineral could be a pure element, but more often minerals are made up of many different elements combined Minerals are useful chemical compounds for making new materials that we can use in our daily lives253 Crushing and milling Mining of mineral resources Sterling silver is an alloy of silver that consis Mineral or chemical fertilizers The 20202025 World Outlook for Parts for Chemical Manufacturing Distilling, Rectifying, Fractionating, Heat Exchange, Dryers, and Gas and Air Liquefying Machinchemical mineral sterling stacjawielopolepl

Lixiviation Plant For Silver Ore Processing

Hyposulphite Lixiviation, the Chlorination Process, ordinary solution ore tanks ounces of silver ounces silver the lixiviation plant is much Production of reagents for mineral processing to zinc and silver The various species of cyanide ZENITH Machinery is a professional enterprise for mineral mining and crushing and grinding, whose mining equipment, , milling machine, mineral processing equipment are exported to all over the world Insider are welcome to come to consult and purchase on selectionThe differences among minerals, rocks, ores, orebody and 2 "Phosphorus and the Phosphides," KirkOthmer Encyclopedia of Chemical Technology, 3rd ed, Vol XVII, 1982, pp 473490 3 Ibid 4 FMC Corporation Comment submitted in response to the Supplemental Proposed Rule Applying Phase IV Land Disposal Restrictions to Newly Identified Mineral Processing Wastes January 25, 1996EPA Identification and Description of Mineral Processing

silver ore crushing process

Silver crushing processing Silver is commonly extracted from ore by smelting or chemical leaching Silver mining is the resource extraction of silver by mining Silver ore beneficiation first choice is large capacity magnetic separation, followed by is electrostatic separation, and then reelection, and the minimum is flotationSilver mining process Silver is commonly extracted from ore by crushing, grinding, smelting or chemical leaching crushers have a very important role in silver ores mining, especially in silver ores’ crushing process The Jaw Crusher is commonly used as the primary crusher and Impact Crusher, Cone Crusher are used as secondary crusherSilver mining equipment, silver crushing and grinding Jan 16, 2016 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum separationCrushing Mineral Processing

crushing silver ore for

Dec 31, 2021 crushing silver ore crusherasiasilver ore mining,silver ore crusher,crushing plant,silver ore silver is a precious metal and more usually combined with sulfur, antimony, arsenic, or chlorine silver is extracted from silver ores by crushing, grinding, smelting or chemical leachingMay 24, 2016 The Silver Cobalt Extraction Flowsheet In this study, the silver occurs essentially as impure native silver together with argentite, cobaltite and other complex sulfides The flowsheet is based on a 400 ton per day concentrator with special emphasis on “recover your mineral as soon as free” CRUSHING Silver Cobalt OreSilver Cobalt Processing by Gravity and FlotationCrushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) Overview of Mineral Processing Methods

OP05 – Mineral Processing (Crushing Screening)

The purpose of this document is to prepare procedures covering the control of crushing and screening operations What does the responsible manager need to do? The responsible manager must ensure that: All parts of the processing plant are suitably inspected and maintained as per Regulation 12(1)(a)(iii) Quarries Regulations 1999The processing of lithiumcontaining minerals such as spodumene, in general, comprises crushing, wet grinding in a ball mill, sizing, gravity concentration, and flotation using a fatty acid (oleic acid) as the collector The major lithium mineral in lithium ore is spodumene, which is considered insoluble in water and dilute acidsMineral Processing an overview ScienceDirect TopicsSILVER CRUSHING PROCESSING COPPER ORE CRUSHING PROCESSING IRON ORE CRUSHING PROCESSING Chemical Agitation Tank Mixer >Concentrating Equipment Vacuum Pressure Filter available mineral processing technology, plant size, required equipment and periodKHM Mining MachineryNO1 in ChinaKINGHONG MACHINE

Mineral Processing Plant, Aggregate Plant, Mineral Ore

Clay As kind of important raw mineral materials, clay mine’s crushing and grinding is extremely important in the whole clay mining processing plant There will be both stationary crushing screening plant and mobile or portable plant provided for your miningWith the ability to maximize product output, our machineries feature high production rates, low operating costs and will involve the crushing and grinding (which is also known by a common name called To obtain the correct degree of liberation in mineral processing – ii To increase the specific surface area of the valuable minerals for in physical (or chemical) properties of the metal and gangue compound in the oreMineral dressing (= Orebeneficiation) kauAug 23, 2016 Main Mineral Equipment Applied in Crushing, Xinhai Crushing is the first stage of the whole mineral processing progress There are also two stages in the crushing progress, which are the primary crushing stage and the second crushing stage Jaw crusher is the major mineral equipment used in the primary crushingMain Mineral Equipment Applied in Crushing xinhaiepc

chemical mineral sterling stacjawielopolepl

Sterling silver is an alloy of silver that consis Mineral or chemical fertilizers The 20202025 World Outlook for Parts for Chemical Manufacturing Distilling, Rectifying, Fractionating, Heat Exchange, Dryers, and Gas and Air Liquefying MachinApr 23, 2021 5 Types of Phosphate Froth Flotation Process Froth flotation is the most widely used phosphate ore separation process Because of the nature of the phosphate ore, such as mineral types and content, disseminated particle size, its Mineral Flotation, Flotation Separation, Forth Flotation