Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

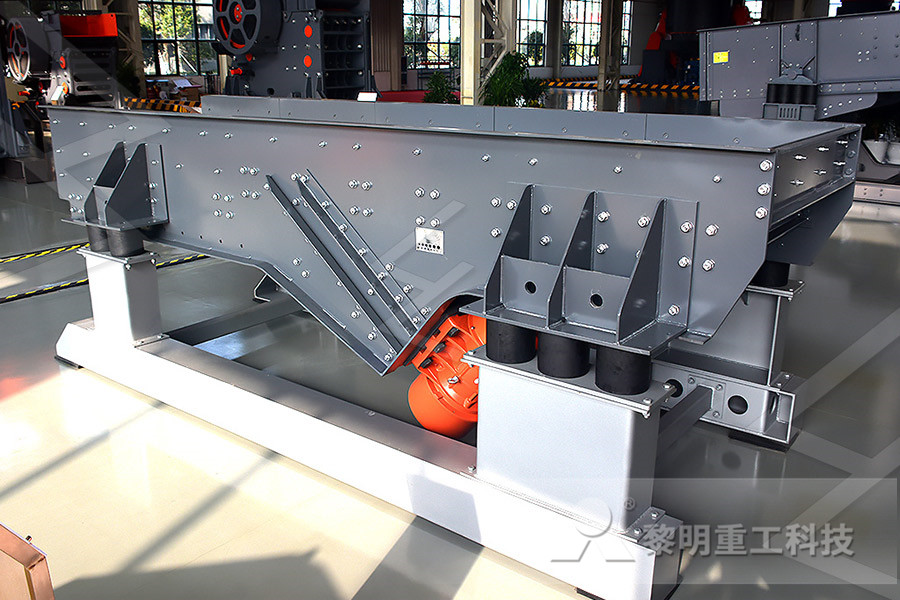

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

b Crushing Cement Production

The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the central vertical spindle and the concave liners (fixed) mounted on the main frame of the crusher The gap is opened and closed by an eccentric on the bottom of the spindle that causes the central vertical spindle to gyratecement crushing process, cement crushing equipment, cement The crushing of cement aims at producing uniform size particles by crushing, grinding and sorting The cement crushing process is a multilevel process and it can be concrete crushing how the process goes Iron Ore Crushing and Screening used for Mining Process Flow Cement Crusher Process Crusher Mills, Cone Crusher, Jaw In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw material during cement productionCement Crushing Grinding Plant,

Cement manufacturing process: Stepbystep guide CCE

Jul 20, 2020 The first step of Cement manufacturing process is to quarry the principal raw materials, mainly limestone, clay, and other materials Step 2: Crushing After quarrying the rock is crushed This involves several stages The first crushing reduces the rock to a maximum size of about 6 inchesAug 30 2012 Its manufacturing includes extraction proportioning grinding After explaining the complete process of cement making flow chart would be Crushing Process Geo Energy Group Crushing Process At the barge loading port the coal is off loaded from the dump trucks onto a conveyor belt which feeds it into the crusher where it is crushedcrushing process explained cementgrindingplantsManufacturing process flow 1 Quarrying and Crushing The quarry (where the mining activity is performed) is located 07 km away from the plant and has the manufacture of Portland cement Gypsum and Pozzolana are going to be used for final cement remaining 5% of the calcinations and clinkerization process will be taken place inside kiln TheManufacturing process flow 1 Quarrying and Crushing

Cement Manufacturing Process Industrial Technology Group

Oct 15, 2021 Cement Manufacturing Process Summary: In brief, cement production has the following 7 steps: crushing and prehomogenization, raw meal preparation, homogenization of raw meal, preheating decomposition, firing of cement clinker, cement grinding and cement package Cement is a powdery hydraulic inorganic cementing materialAn Explanation of the Soybean Crush Odell s World In the soybean industry the term crush represents bath a physical process as well as a value calculation The physical crush is the process of converting soybeans into soybean meal and soybean oil The crush value is a dollar amount determined by the price of soybeans relative to the combined crushing process explained cementgrindingplantsCrushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing" Although there is no limit set, the downsizing process over 3 mm is considered as "crushing What is the crushing process? MEKA

Manufacturing process flow 1 Quarrying and Crushing

Manufacturing process flow 1 Quarrying and Crushing The quarry (where the mining activity is performed) is located 07 km away from the plant and has the manufacture of Portland cement Gypsum and Pozzolana are going to be used for final cement remaining 5% of the calcinations and clinkerization process will be taken place inside kiln TheJan 27, 2020 Crushing of cement raw materials is a process to cut large particles into a smaller sizes The raw material of cement usually include limestone, clay, shale, tripoli, and others, limestone is always the main composition, for reducing g the transportation cost, most cement plant would be located near the limestone quarry Cement Manufacturing Process: 6 StepsTo Make Cement The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production;Technology How To Crushing And Grinding Cement Plant

New dry process cement production line process LCDRI CN

Aug 26, 2019 The mineral of the Portland cement clinker is mainly composed of tricalcium silicate, dicalcium silicate, tricalcium aluminate and tetracalcium aluminoferrite Third, the process 1 Fragmentation and prehomogenization (1) In the process of crushing cement production, most of the raw materials are crushed, such as limestone, clay, iron ore and Oct 29, 2019 New Dry process Cement Method Technological Process Crushing and prehomogenizing Raw materials preparation Raw material homogenization Preheat decomposition (1) Material dispersion (2) Gassolid separation (3) predecomposition Firing of cement clinker Cement milling Cement packagingDry Process Of Cement Manufacturing\Dry Process Of Cement Aug 30, 2012 Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material (like limestone) releases the carbon dioxideCement Manufacturing Process Phases Flow Chart

Wet Process; Dry Process; Cement; Crushing; Milling

Humanoid Based Intelligence Control Strategy of Plastic Cement Die Press WorkPiece Forming Process for Polymer Plastics Dekuan Liu , Shuang Jin , Hu Xu Journal of Materials Science and Chemical Engineering Vol4 No6 ,May 24, 2016finish mill for cement process Jul 18, 2012 – Gulin crushing, screening, grinding and washing plant play a great role in aggregate production, ore processing finish mill process of cement Mining Quarry PlantAnswer (1 of 4): 1 In this process, raw materials (limestone and clay ) are grind in dry condition 2 They are fined by crushing, grinding and then blending and they are passed through sieve no200 3 It is passed to rotary lion and heated to 1450°C What is dry process in cement manufacturing? Quora

Cement Manufacturing Process: What is Cement made of

Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry stateOct 15, 2021 Cement Manufacturing Process Summary: In brief, cement production has the following 7 steps: crushing and prehomogenization, raw meal preparation, homogenization of raw meal, preheating decomposition, firing of cement clinker, cement grinding and cement package Cement is a powdery hydraulic inorganic cementing materialCement Manufacturing Process Industrial Technology GroupAn Explanation of the Soybean Crush Odell s World In the soybean industry the term crush represents bath a physical process as well as a value calculation The physical crush is the process of converting soybeans into soybean meal and soybean oil The crush value is a dollar amount determined by the price of soybeans relative to the combined crushing process explained cementgrindingplants

Technology How To Crushing And Grinding Cement Plant

The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production;Oct 29, 2019 New Dry process Cement Method Technological Process Crushing and prehomogenizing Raw materials preparation Raw material homogenization Preheat decomposition (1) Material dispersion (2) Gassolid separation (3) predecomposition Firing of cement clinker Cement milling Cement packagingDry Process Of Cement Manufacturing\Dry Process Of Cement In the production process, large stones are evenly sent to the jaw crusher by a vibrating feeder for coarse crushing (primary crushing), then sent to the impact crusher by the belt conveyor for secondary crushing After that, all the stones will be divided into three different sizes on the vibrating screenStone Crushing Plant Cement Equipment In Cement Plant

Raw Material Crushing and PrehomogenizationDry Process

During cement manufacturing process, the majority of raw materials, including limestone, clay, iron ore, coal, etc will be crushed Specifically, due to larger granularity and higher hardness, the crushing of limestone that is maximally consumed in cement process plays critical role in the raw material crushingSimilar to the dry process, materials also need to undergo quarrying, primary crushing, secondary crushing, proportioning and grinding in the raw materials preparation stage of the wet process The biggest difference between the two methods is that in the wet process, water is usually required as a process media added in the raw mix to form slurryWet Process of Cement Manufacturing Cement Wet Process The cement manufacturing process in the plant can be divided into seven steps: Step 1 – Raw Material Crushing Pre Homogenization: In the Portland cement manufacturing process, most raw materials need to be crushed first, such as limestone, clay, iron ore, and coalPortland Cement Plant for Sale New Dry Process of

(PDF) Cement Manufacturing ResearchGate

cement is made by heating limestone (calcium carbonate) with other materials (such as cla y) to 1450 °C in a kiln, in a process known as calcinations, whereby a molecule of carbon dioxide is Aug 29, 2013 Name of the Post : Cement plant Pyro Process and VRM CCR Operators pdf types of pneumatic flotation cell; mini pavement recycling plant; ccr operator jobs in cement industry 2012 in varanasi new cement plant in salalah the book quot; the modern gold we are looking for a ccr operator from process field for operation of cement plantprocess of ccr in cement plant pdf bool miningcrushingCement Production Process 1 Crushing In cement plant, most of the material needs to be broken, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw material in cement production, so the crushing stage plays a very important role in cement plant 2 Raw material grindingCement Production Process Yuhong Heavy Machinery Co,Ltd

CNA Limestone crushing process Google Patents

The invention discloses a crushing process, and particularly relates to a limestone crushing process The crushing process is the twostage open circuit crushing and comprises the following steps that: raw ores are subjected to firststage crushing in a firststage screeningcrushing machine, the crushed materials are subjected to firststage screening, the oversize Apr 02, 2013 Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns Cement Plant EquipmentCement ProcessCement Production Line Cement equipment manufacturer kefid supplies cement plant machines:stone crusher, cement mill, ball mill for cement processing in cement grinding plantwhat is finish mill of a cement process Mining Quarry Process Engineer (Cement Industry) stone – JB Al Process Engineer (Cement Industry) Arkan building Materials a) Establish, monitor and maintain standards for key operating parameters b) Propose new projects in order Process Of Prehomogenation In Cement Industries Crusher