Solutions

Products

-

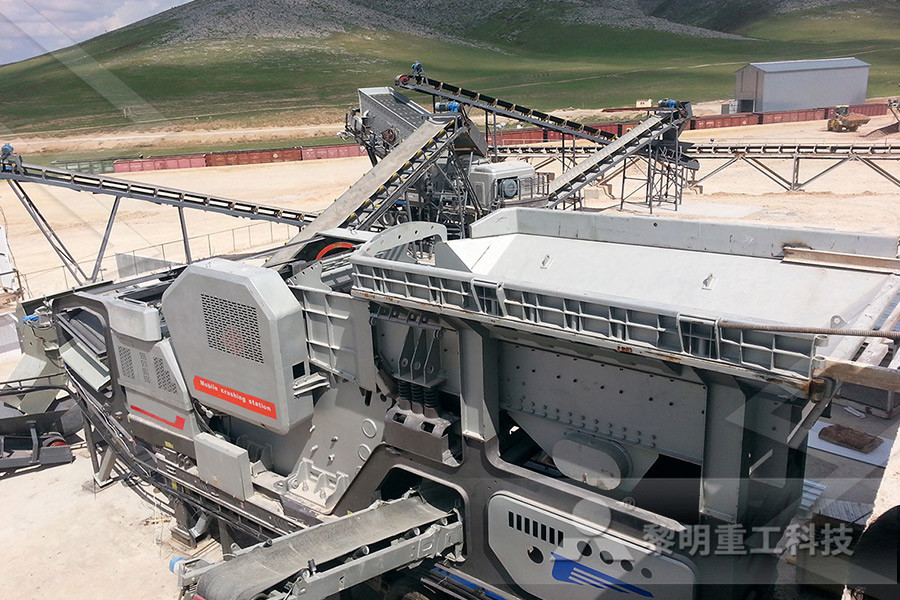

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Parameter Selection Calculation Power

30/08/2019 there are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of grinding (product size), the uniformity of the feeding material, and the portion of loaded, , and the mill structure (the mill barrel length, diameter ratio, 19/06/2015 the basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, bond work index, bulk density, specific density, desired mill tonnage capacity dtph, operating % solids or pulp density, feed size as f80 and maximum ‘chunk size’, product size as p80 and maximum Ball Mill Design/Power Calculation13/02/2017 the apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ ball mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where Ball Mills Mineral Processing Metallurgy

The Most Important Parameters Of Planetary Ball Mill

23/04/2018 The Most Important Parameters Of Planetary Ball Mill: Speed Apr 23, 2018 Rotation speed is an extremely important settable parameter of planetary ball mill Different rotation speeds directly affect the grinding, mixing and uniform dispersion of planetary ball millsBall Mill Design Parameters Size rated as diameter x length Feed System One hopper feed Diameter 40 – 100 cm at 30 ° to 60 ° Top of feed hopper at least 15 meter above the center line of the mill Feeder Single or double helical scoop feeder or a spout feeder Double helical feeders used in closedcircuit with classifiersAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Ball Mill Design/Power Calculation The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and ball mill perameters grinding machines ncmt

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON

Mill speed, mill charge, ball size, and wet grinding are the parameters which have been selected for the present study It is hoped that the analysis of the data acquired will allow insight as to which parameters will require a functional form if they were to be integrated intoE1 Determination of milling parameters in each ball size interval 100 E2 Predicted EQM and OEMBSD’s selection functions 100 E3 Statistical analysis of the predictions 101 9 List of figures Figure Page 21 Breakage mechanisms in a ball mill 22 22 First order reaction model applied to milling 24 23 Grinding rate versus particle size for a given ball diameter 25 24 EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERSparameters of the planetary ball milling: weight ratio of ball to powder, ball size, type of milling medium, volume of medium and the rotation speed were optimized by Tagu (PDF) Parameters optimization in the planetary ball

Milling Parameters

The end mill speed is calculated with the following formula: n [rpm] = (vc [m/min] *1000) / 314 * ø d1 [mm]) Example calculation: vc = 500 m/min (selected from chart) d = ø 8 mm 19904 rpm = (500 *1000) / (314 * 8) If the maximum speed of the milling motor is lower than the calculated value, the maximum speed of the milling motor needs to be inserted into the formula for the Ball Mill Technical Parameter List Ball Mill Main Technical Parameters ball mill technical parameter list Ball Mill Main Technical Parameters,Ball mill,Ball mills,Ball mill machines Machinery Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractoryball mill technical parametr amenexfrHighEnergy Ball Mill Parameters Used to Obtain research was to study the different milling parameters (time, ball, HighEnergy Ball Mill Parameters Used to Obtain UltraFine Portland Cement at Laboratory Level Get Price EFFECT OF BALL SIZE DISTRIBUTION ON MILLING EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS, 21 Breakage ball mill milling parameters gitedesvendangesfr

(PDF) Ball milling: an EvT parameter phase diagram

Ball milling procedure energy and the frequency of the shocks An addi 10 g of some meltspun ribbon pieces (the tional modification allows a heating of the ball mill processing parameters have a significant effect on energy consumption and the quality characteristics of the obtained product However, relatively little research has been published considering the use of ball mill for fat filling production This research investigated the interaction effects and optimization of main ball milling variables (agitator shaft speed and OPTIMIZATION OF THE BALL MILL PROCESSING PARAMETERS Mill load (ML) estimation plays a major role in improving the grinding production rate (GPR) and the product quality of the grinding process The ML parameters, such as mineral to ball volume (PDF) Modeling of operating parameters for wet ball

ball mill control parameters aupetitecureuilfr

Ball Mill Design Parameters Of Vibrating Ball Mill Appliion Parameters Ball mill is an vibrating screen for sag mill beltconveyers SAG Mill Control More Info Be up to date process model to bring the control parameters as mize control of the first ball mill Siemens has now started work on the second mill and the More Info Ball Mill Parameters Grinding Mill China ball mill Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of Ball Mills Drum ball mills Jetmills Beadmills Horizontal rotary ball mills Vibration ball mills Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final Ball Milling University of Massachusetts BostonWith a view to developing a sound basis for the design and scaleup of ball mills, a large amount of data available in the literature were analyzed for variation of the two key mill performance parameters: power specific values of the ‘absolute breakage rate of the coarsest size fraction’, S *, and ‘absolute rate of production of fines’, F *, with some of the important operating and Analysis of ball mill grinding operation using mill power

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a Again, the size of the vessels is an essential parameter for the efficiency of the process as a higher distance allows a higher kinetic energy and therefore stronger impacts Fig 2 (a) Schematic representation of a ball mill (horizontal section); (b) different types of instruments (this figure has been adapted from ref 19 with permission from Planetary Ball Mills are used wherever the highest degree of fineness is requiredIn addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization Planetary Ball Mill PM 100 RETSCH highest fineness23/04/2018 The Most Important Parameters Of Planetary Ball Mill: Speed Apr 23, 2018 Rotation speed is an extremely important settable parameter of planetary ball mill Different rotation speeds directly affect the grinding, mixing and uniform dispersion of planetary ball mills Can not find a suitable speed, from the work efficiency is reduced, the effect becomes worse, The Most Important Parameters Of Planetary Ball Mill

Parameters Affecting The Ball Mill Operating Ball Mill

Parameters Affecting The Ball Mill Operating The effect of ball mill operating parameters on operating parameters mill speed mill charge ball size and wet grinding are the parameters which have been selected for the present study it is hoped that the analysis of the data acquired will allow insight as to which parameters will require a functional form if they were to be 19/06/2015 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type Ball Mill Design/Power Calculationball mill perameters sep 26, 2020 — in this study, the effect of types, feed sizes, and ball surface area have been investigated on the morphology of ground quartz particles Send Message Get a Quote Last News tin ore ball mill indonesia suplier ball mill ball feed in canada china ball mill in gauteng for sale tungsten carbide ball mill vials supplier for ball mill for ball mill perameters

What Are The Parameters Of Efficiency Of Ball Mill

E1 Determination of milling parameters in each ball size interval 100 E2 Predicted EQM and OEMBSD's selection functions 100 E3 Statistical analysis of the predictions 101 9 List of figures Figure Page 21 Breakage mechanisms in a ball mill 22 22 First order reaction model applied to milling 24 23 Grinding rate versus particle size Ball Mill Design Parameters Of Vibrating Ball Mill Appliion Parameters Ball mill is an vibrating screen for sag mill beltconveyers SAG Mill Control More Info Be up to date process model to bring the control parameters as mize control of the first ball mill Siemens has now started work on the second mill and the More Info Ball Mill Parameters Grinding Mill China ball mill ball mill control parameters aupetitecureuilfrball mill perameters mtm mill grinding There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyOur leading products have crushing equipment, sand making ball mill perameters mtm mill grinding

Influences of operating parameters on dry ball mill

parameters such as mill speed, ball filling ratio, ball size distribution, powder filling ratio, grinding aid dosage and grinding time were studied The results of grinding tests were evaluated based on the product particle size (d 50, d 80) and surface area (m2/kg) As a result of this study, optimum grinding test conditions determined to be 70% of Nc, J=035 for ball filling ratio, 40 mm (10 13/06/2013 ball mill milling parameters + More Coal Powder Processing $ + $?125:00 Live Chat + More Lime Industry $ + $?125:00 Live Chat + More Petroleum Coke Processing $ + $?125:00 Live Chat + More Ground Calcium Carbonate Processing $ + $?125:00 Live Chat + More Calcite Powder Production Line in Vietnam $ + $?125:00 Live Chat + More Calcite ball mill milling parameters cucinanapoletanafrThe ball mill Ball milling is a Again, the size of the vessels is an essential parameter for the efficiency of the process as a higher distance allows a higher kinetic energy and therefore stronger impacts Fig 2 (a) Schematic representation of a ball mill (horizontal section); (b) different types of instruments (this figure has been adapted from ref 19 with permission from Ball milling: a green technology for the preparation and