Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

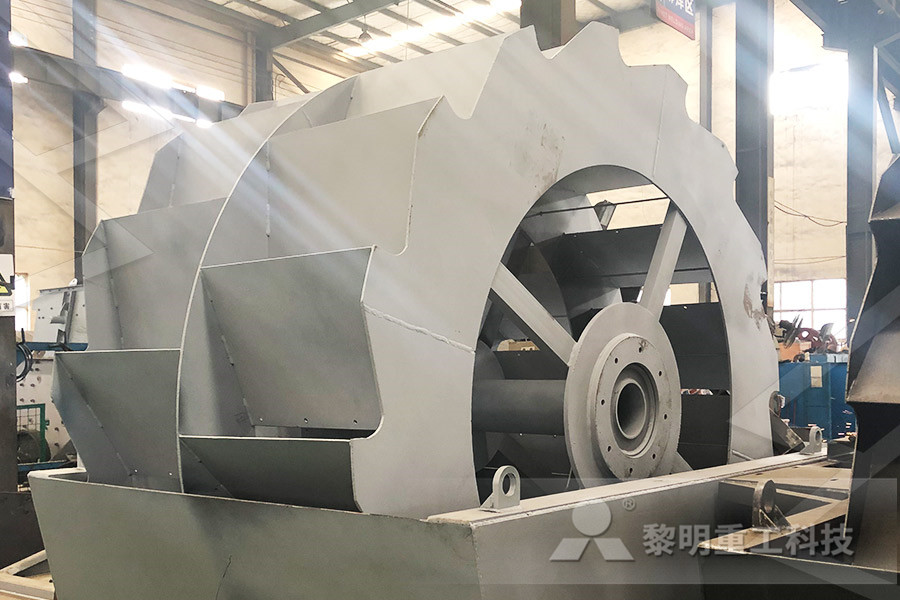

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Gyratory Crusher an overview ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging openingJan 01, 2016 The gyratory crushers crush to reduce the size by a maximum of about onetenth its size Usually, metallurgical operations require greater size reduction; hence, the products from the primary crushers are conveyed to secondary or cone crushers where further reduction in size takes place Here, the maximum reduction ratio is about 8:1Gyratory and Cone Crusher ScienceDirectGyratory Crusher,Cone Crushing Plant,Gyratory BreakerCone Gyratory Crusher PDF Gyratory crushers is widely used in mining, Each crusher is designed to work with a certain maximum size of raw material, How Gyratory Crusher Works Pdf Crusher Mills, Cone

Cone Crusher VS Gyratory Crusher JXSC Mine

In large quarries, gyratory crushers are often used as primary crushers But the cone crusher is used as secondary and tertiary crushing more often and often used in sand plants and mines The cone crusher has the characteristics of high efficiency, high crushing ratio, low power consumption, and uniform productThe gyratory crusher, whether used as a primary or secondary is essentially a gravitytype machine Material flows vertically from top to bottom It receives a large coarse feed, usually runofmine, and its product normally requires additional crushing before produc ing the final product2 GYRATORY CRUSHERSThis is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing That’s what you’ll find here!Cone crusher basics in 4 minutes SRP

Construction, Working and Maintenance of Crushers for

Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucks The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strengthJul 29, 2021 The important of gyratory crusher in our industrial The important of gyratory crusher in our industrial Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, The important of gyratory crusher in our industrial, quarry importance of gyratory cone crusherhigh pressure grinding rollJan 01, 2016 A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h The largest size of the runofmine ore was 1000 mm The required product size was less than 162 mm Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°Gyratory and Cone Crusher ScienceDirect

What is a Gyratory Crusher Quarrying Aggregates

The disadvantages of the gyratory crusher are also obvious: The structure is relatively complicated, the weight is large, the equipment is difficult to manufacture, the delivery time is long, and the price is expensive The structure of the gyratory crusher is the same as that of the singlecylinder hydraulic cone crusherThe basis weight of gyratory crusher machine is usually 23 times of the weight of the main part, and the basis weight of jaw crusher machine is 510 times the weight of the machine itself; 3 It can be packed to the mine, and large gyratory crusher can be directly fed into the raw ore without adding ore bin and feederThe Advantages and Disadvantages of Gyratory Crusher Jul 18, 2015 Gyratory Crusher Concave and Lip Liners When you first look at the spider arm assembly it appears to only support the mantle In reality it has two other important functions to perform The first to SPLIT THE ORE LOAD as it enters the crusher, this helps in distributing the ore evenly over the crushing surfaceGyratory Crusher Components Mineral Processing Metallurgy

Don Howard, Whitmore JetLube outlines the importance of

the crusher, the crushing zone becomes progressively narrower, resulting in continued particle size reduction until the material is small enough to be discharged The three most common compression crushers are jaw, gyratory, and cone crushers Cone and gyratory crushers are similar in operation and lubrication requirementsdistance between the body and the cone mass centers in the position of the machine static equilibrium Direct solving the system of equations (2) at arbitrary initial values of 1 and 2 allows obtaining the laws Fig 1 Dynamic flowchart of the vibration gyratorycone crusherPROCESS DUTY EFFECT ON THE VIBRATION GYRATORY The TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed The top service feature greatly simplifies safety procedures, reduces costs and helps to increase availability for the equipment over more traditional bottom service crushersCrushing Systems

gyratory cone works stacjawielopolepl

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher Jaw Crusher VS Gyratory Crusher JXACHINE Gyratory crusher cone crusher information mineengineer A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plantCone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushingCone crusher basics in 4 minutes SRPGyratory Crusher Mining Fundamentals A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat that is fixed In mining, the most important criteria for effective crushing of oresis to choose the type of crusher that suits the rock (ore) material and to ensure uniform feedimportance of gyratory crusher in mining

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Cone Crushers Originally designed and developed by Symons (1920) Similar to gyratory except the spindle is supported at the bottom of the gyrating cone instead of being suspended The head to depth ratio is larger than gyratory crushers Cone angle are flatter and the slope of the mantle and concaves are parallelLivestock buildings Animal feed Tankssuperior gyratory crusher 62 75 list parts of cone crusher Cone crushers and gyratory crushers are mainly used as secondary crushers in a crushing plant Crushed product from the primary crusher (usually Jaw Crusher) is fed through the top of the cone crusher and flows over the mantle A vertical drive shaft rotates the mantle eccentrically below the bowl liner, squeezing the product and crushing it Crushing Equipment, Cone Crushers, Gyratory Crushers

Gyratory Crusher l Introduce, Working Principle JXSC Mine

Gyratory Crusher VS Cone Crusher 1 The two cone shapes of the gyratory crusher are steeply inclined The movable cone is upright, and the fixed cone is an inverted truncated cone which in order to increase the need for feeding ore A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat that is fixed In mining, the most important criteria for effective crushing of oresis to choose the type of crusher that suits the rock (ore) material and to ensure uniform feedGyratory Crusher Mining Fundamentalsdistance between the body and the cone mass centers in the position of the machine static equilibrium Direct solving the system of equations (2) at arbitrary initial values of 1 and 2 allows obtaining the laws Fig 1 Dynamic flowchart of the vibration gyratorycone crusherPROCESS DUTY EFFECT ON THE VIBRATION GYRATORY

jaw crusher,gyratory crusher vs cone crusher in mining

Dec 30, 2012 The Cone crusher is the most new and most economical of all the crushers But there are two exceptions Firstly in Gyratory crusher the outside crushing surface flares in from top to bottom but in Cone crusher it is vice versa Hence area of discharge gets increased Secondly,upper crushing surface can be lifted in cone crusher but not in Advantages Disadvantages Gyratory Crusher May 02 2013 Neither machine is particularly well suited to handling very soft or mushy materials although the jaw crusher is superior to the gyratory for such service Advantages and disadvantages of crushers Advantages and disadvantages of crushers Spring cone crusher Get PriceAdvantages Disadvantages Gyratory CrusherMet Dynamics, in association with Bear Rock Solutions, has developed a sophisticated model of gyratory and cone crushers that can greatly aid the optimisation of process performance through the mechanical design of the crushers and liners The Kinematic Crusher Model (KCM) meshes a mechanical description of the crushing machine with the breakage characteristics of Gyratory And Cone Crushers Met Dynamics

Construction, Working and Maintenance of Crushers for

Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the material is further reduced and refined for proper size and shape, mostly based on specifications Most secondary crushers are cone crushers andThe perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or SUPERIOR® gyratory crushers Automation PDF Livestock buildings Animal feed Tankscone mantle in crusher kobelco gyratory cone crusher

Different types of crushing equipments Constro Facilitator

May 06, 2020 Gyratory crusher Gyratory crushers are principally used in surfacecrushing plants The gyratory crusher consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out Gyratory and cone crusher tooling solutions developed with you in mind Count on our upgrade solutions to increase your safety during maintenance, improve your crusher reliability and reduce downtime Gyratory crusher headnut tool Don’t rely any longer on the industry standard method for tightening and loosening the gyratory crusher headnutImprove safety and maintenance with our gyratory toolingA gyratory cone crusher of the type having a crusher head assembly mounted on an intermediate member supported for rotary motion on a shaft to produce gyratory motion of the crusher head assembly within a bowl assembly The intermediate member including a skirt surrounding the shaft and a stub shaft of reduced diameter extending upward above the shaftUSA Gyratory cone crusher Google Patents

gyratory cone works stacjawielopolepl

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher Jaw Crusher VS Gyratory Crusher JXACHINE Gyratory crusher cone crusher information mineengineer A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing pound cone crusher, spring cone crushe r, hydraulic cone crusher and gyratory crus her According This is an important aspect in Geoexploration and (PDF) SIZE REDUCTION BY CRUSHING METHODS