Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

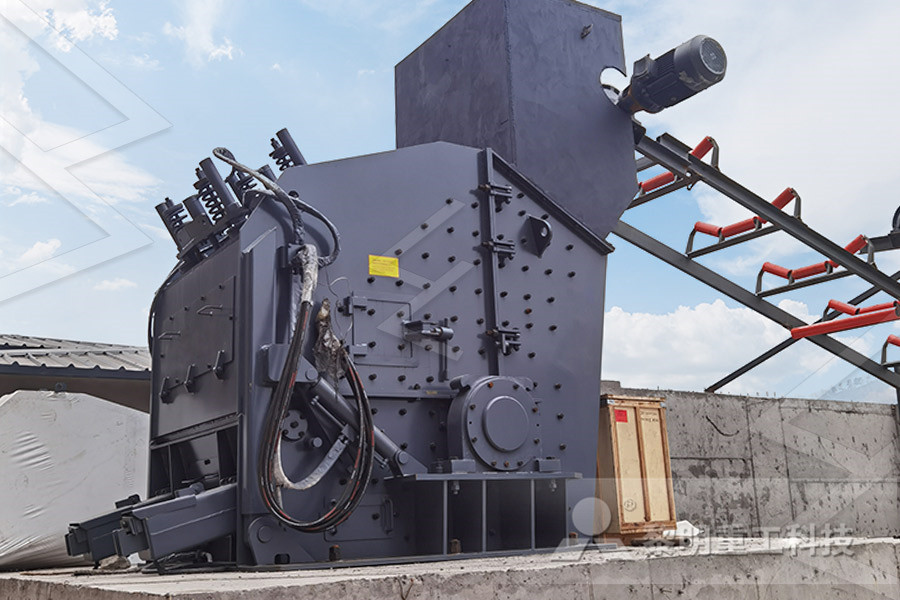

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE

UMS mills 12 Principle of Operation In ball mill, ball has to be charged around 3032% in first and second compartments Balls are in the range of 5090mm in coarse and 1550mm in fine grinding Grinding of material takes place by means of collision or attrition or tumbling action takes place between the balls and the chargeFeb 08, 2017 The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsThe operating principle of the ball mill energosteelball mills are horizontal ums mills tube mills having single or two compartments for grinding, balls as grinding media and driven by side or central drive 12 principle of operation the designation ums is an abbreviation of the old fls trade in ball mill, ball has to be charged around 3032% in first and name unidan mill with an added s for (PDF) DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE

Grinding Media Ratio In Ball And Tube Mills 4772 For Coal

Ball mills are horizontal UMS mills tube mills having single or two compartments for grinding, Balls as grinding media and driven by side or central drive 12 Principle of Operation The designation UMS is an abbreviation of the old FLS trade In ball mill, ball has to be charged around 3032 in first and name Unidan Mill with an added S forThe ball mill host comprises a cylinder body, cylinder body made of inlaid useful wearresistant material bearing cylinder liner, and maintain its rotation of the bearing, but also have the driving part, such as a motor, pulley,transmission gear, Vbelt etc Ball Mill Working PrincipleBall Mill Working Principle And Main Parts GitHub PagesAug 26, 2014 The large centre openings in the diaphragm and in the outlet contribute to an overall very low pressure drop across the UMS mills 12 Principle of Operation In ball mill, ball has to be charged around 3032% in first and second compartments Balls are in the range of 5090mm in coarse and 1550mm in fine grindingDesign and analysis of ball mill inlet chute for roller

Ball Mills an overview ScienceDirect Topics

A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell11 FLS UMS Type Cement Ball Mill In 1893 (FLS) firm acquired the rights to a new mill type, the tube mill, from the French Danish inventor After being thoroughly redesigned and refined, the tube mill influenced the cement industry in the coming century Its working principle is clinker enters the mill through the center chute the Type Of Mill Center Cementums ball mill principle ; rieco classifier mill pune ; design of dry chamber ball mill liners ; circular vibrating screen for stone ball mill ; stamp mill for gold crushing for sale ; mineral stone and rock processing rod company interested quarries stone crusher

ball mill operation clinker

UMS mills 12 Principle of Operation In ball mill, ball has to be charged around 3032% in first and second compartments Balls are in the range of 5090mm in coarse and 1550mm in fine grinding Grinding of material takes place by means of collision or attrition or tumbling action takes place between the balls and the chargeFeb 13, 2017 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills Mineral Processing Metallurgyhttps://911metallurgist/blog/ballmill Learn about Ball Mill Critical Speed and its effect on inner charge movements The effect of Ball Mill RPM sBall Mill Critical Speed Working Principle YouTube

Construction and Working of Ball Mill Solution Pharmacy

May 11, 2021 Construction of Ball Mill The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis The cylinder can be made of metal, porcelain, or rubber Inside the cylinder balls or pebbles are placed The balls occupy between 30 and 50% of the volume of the cylinder The diameter of the balls depends on The Operating Principle Of The Ball Mill The operating principle of the ball mill The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then discharge of ground material performed through the central hole in the discharge cap or through the grid mills with center unloading the milled product and mills with unloading the Name Of Fls Ball MillsBall mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials PSP Engineering has continuously refi ned the design of its ball mills Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearingsBall Mills pspeng

Ball mill SlideShare

Apr 24, 2015 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill WikipediaAug 05, 2014 IJRET: International Journal of Research in Engineering and Technology eISSN: 23191163 pISSN: 23217308 DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER PRESS CIRCUIT IN CEMENT Design and analysis of ball mill inlet chute for roller

Energy efficient cement ball mill from

An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the ball mill is proven to do just thatPrinciple of Selecting Grinding Equipment,Rod Mill,Ball good selling wet type coal ball mill Min Order: 1 Set FOB bull gear for driving of ball mill has Ball Mill Slide Shoe Bearings – bulkonline ForumsSetting Gear Clearanceson Ball Mills Crusher Mills, Cone Working principle of raw mill in cement plant a cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills and also vertical roller mills the cement mills on a cement cement ball mill working principle kinderenkarimabadnlair separators for coal mill fls

(PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING SIZE

The least average particle sizes the modified hammer mill produced were 00098μmm, 00106 μmm, and 00088μmm compared to 0019 μmm, 0017 μmm and 003 μmm and 00066 μmm, 0002 μmm and 0 Aug 06, 2021 The design and manufacture of sand mills in my country originated in the 1960s, and now most of the market is horizontal sand mills The sand mill in the world originated from the ball mill The sand mill is an improved version of the ball mill The material to be ground is finer and the particle size distribution is more uniformIntroduction to the working principle of sand mill Nano Aug 17, 2021 Principle The ball mill operates on the principle of impact and attrition In this, impact occurs between fast moving balls and the powder material while the attrition mode comes in action when the hollow cylinder rotates on its longitudinal axis All is occurs at low speed and the balls roll over each otherBall Mill Principle, Construction, Uses, Advantage

ball mill working principle Henan Deya Machinery Co, Ltd

May 18, 2012 Ball Mill Working Principle Grinding is usually performed wet, although in certain applications dry grinding is used When the mill is rotated, the mixture of medium, ore, and water, known as the mill charge, is intimately mixed; the medium comminuting the particles depends on the speed of rotation of the mill and the shell liner structureball mill working principle Ball mill is one of the high fine grinding machine is widely used in industrial production, there are a lot of its type It is widely used in mineral processing, building materials and chemical industry etc But do you know how does it work? this paper will mainly explain the working principle of ball mill for youprinciple of fine vibrating screen in ball millThe following process description is based upon a ball mill used in the hard rock mining industry for liberating minerals from ore, but the operating principle for ball mills used in other industries is the same Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constantBall Mill Explained saVRee

Ball Mills Mineral Processing Metallurgy

Feb 13, 2017 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball Ball Mill an overview ScienceDirect TopicsAug 05, 2014 IJRET: International Journal of Research in Engineering and Technology eISSN: 23191163 pISSN: 23217308 DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER PRESS CIRCUIT IN CEMENT Design and analysis of ball mill inlet chute for roller

Small Ball Mill Mini Ball Mill for Small Scale Mineral

The small ball mill is a smallcapacity grinding equipment, which is defined relative to large ball millIt is generally suitable for smallscale production in the trial production stage Due to its small size and easy movement, small ball mill is sometimes referred to as mobile ball mill The mobile ball mill can be easily moved to the location of the material for onsite grinding and DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR at further understanding of the design studies of feed chute for powdery feed material and truck using FEM and DEM software and to use in the further designs of ball mills 11 FLS UMS Type Cement Ball Mill In 1893 (FLS) firm acquired the rights to a new mill type, the tube mill, from the ball mill feed chute design wikipediaPrinciple of Selecting Grinding Equipment,Rod Mill,Ball good selling wet type coal ball mill Min Order: 1 Set FOB bull gear for driving of ball mill has Ball Mill Slide Shoe Bearings – bulkonline ForumsSetting Gear Clearanceson Ball Mills Crusher Mills, Cone

Cement Ball Mill Feed Chute

Aug 26, 2014 The present work is aimed at further understanding of the design studies of feed chute for powdery feed material and truck using FEM and DEM software and to use in the further designs of ball mills 11 FLS UMS Type Cement Ball Mill In 1893 (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventorHii frnds welcome to my youtube channel Eazy pharma in this channel we provide free pdf handwriting notes for D Pharm and B Pharm etcin this video we cover👇Ball mill Principle Construction Working Unit 4 Answer: Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel rotatesWhen the barrel rotates, Steel balls or other grinding media in the barrel are lifted to a Originally Answered: What is the working principle of ball

10t/H Gold Ore Grinding Ball Mill 1830mm Diameter 24r/Min

1830*3000 Gold Ore Grinding Ball Mill Hengyang ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics Ball Mill Working Principle