Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

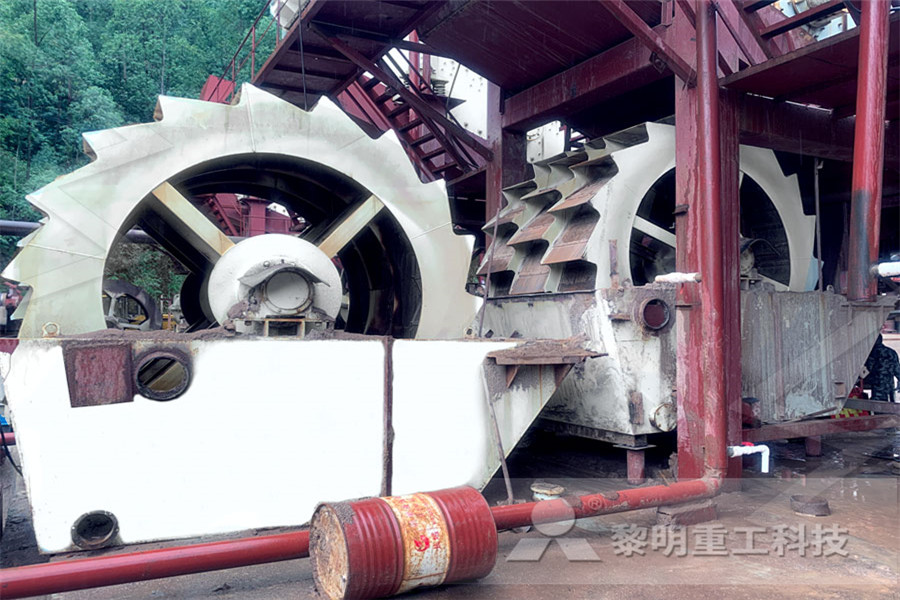

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Dry Process for Manufacturing of Cement GharPedia

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill The raw materials are dried and reduced in size to a fine powder in to grinding mill The dry powder is called the raw meal The raw meal is pumped into a blending siloDescription of New Type Dry Process Cement Production Line This new type dry process cement production line is a kind of process mainly used for small medium and largescale cement plants Its preheater employs outside kiln precalciner C Cement Industrial Efficiency Technology amp Measurescement production process dry process crushingfNow let’s know the manufacturing of cement by the dry process DRY PROCESS When the available raw materials are quite hard, then this process is used The cement by this process can be prepared by using the following operations: Mixing of raw materials Burning and GrindingManufacturing of Cement By Dry and Wet Process

Dry Process Of Cement Manufacturing Dry Cement

The new dryprocess of cement manufacturing technology makes good use of the limestone resources discarded in the traditional mining method and applies the pre decomposition technology, suspension preheating technology, and multichannel burner to reuse the recycled and lowquality fuelsCement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet processHow Cement Is Made Portland Cement AssociationCement production processes can be categorized as dry, semidry, semiwet, and wet processes depending on the handling of raw material before being fed to the rotary kiln Nowadays, almost all new plants are based on the dry process and many old wet plants are also remodeled to dry or semidry processesCement Production an overview ScienceDirect Topics

Cement Manufacturing Institute for Transportation

Aug 03, 2018 Cement Manufacturing Process Cement Manufacturing Process Cement Manufacturing Process CaO SiO 2 Al 2 O 3 Fe 2 O 3 MgO Loss Generalized Diagram of a Long Dry Process Kiln Burner Kiln hood Clinker cooler Clinker Exit gases Kiln feed Dehydration zone Calcination zone Clinkering zone Cooling zone Gas Temp Mat’l temp 450°C 840°FProcess Discretion: Wet process, Semidry process, Dry process and Finish process The environmental im pact of the cement production and its variations between different cement plants, using Life (PDF) Cement Manufacturing ResearchGateAug 30, 2012 Production of cement completes after passing of raw materials from the following six phases These are; Raw material extraction/ Quarry Grinding, Proportioning and Blending Preheater Phase Kiln Phase Cooling and Final Grinding Packing Shipping Cement Manufacturing Process Phase 1: Raw Material ExtractionCement Manufacturing Process Phases Flow Chart

116 Portland Cement Manufacturing

Aug 17, 1971 Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts for 95 percent of the hydraulic cement production in the United States The balance of domestic cement production is primarily masonry cement Both of these cement process crushing instituteofsafetyco CEMENT MANUFACTURING PROCESS AND ITS SELECTION This process was especially evolved to counter the main drawback of the wet process i e high fuel consumption In this process the raw materials ground in dry condition are homogenized and then nodulised in a pan noduliser of dish or rotary type by adding controlled cement production process dry processcrushingfThe new dryprocess cement production line technology was developed in the 1950s, so far, the new dry process cement equipment rate of Japan, Germany, and other developed countries have accounted for 95% This cement production process regards the suspension preheating and pre decomposition as the core, and has the advantages of small pollution Dry Process Of Cement Manufacturing Dry Cement AGICO

cement production process dry process28crushingf

cement production process dry process28crushingf cement production process dry process28crushingf Products CEMENT MANUFACTURING PROCESS AND ITS Since [ protected] Mobile Crushers, mobile crusher plant price Welecome HOME; ABOUT; PRODUCT; CONTACT; Go to HOME; ABOUT; PRODUCT Apr 29, 2021 Cement manufacturing process involves various raw materials and processes Cement is a greenish grey coloured powder, made of calcined mixtures of clay and limestone When mixed with water becomes a hard and strong building materialIt was first introduced by a British stone mason, Joseph Aspdin in 1824, who cooked cement in his kitchen He heated []Cement Manufacturing Process Sanghi cementDry process The raw materials are crushed and fed in the correct proportions into a grinding mill, where they are dried and reduced in size to a fine powder The dry powder, called raw meal, is then pumped to a blending silo, and final adjustment is now made in the proportions of the materials required for the manufacture of cementManufacture of Portland cement University of Technology

116 Portland Cement Manufacturing

Aug 17, 1971 Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts for 95 percent of the hydraulic cement production in the United States The balance of domestic cement production is primarily masonry cement Both of these Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is that in the dry process, calcareous and argillaceous raw materials are fed into the burning kilns in a perfectly dry stateCement Manufacturing Process: What is Cement made ofThe Cement Manufacturing Process Thermo Fisher Aug 20, 2015 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kilncement production processes daikichisushifr

Cement manufacturing process SlideShare

Jun 10, 2014 Evolution of the cement Process • Wet process easiest to control chemistry better for moist raw materials • Wet process high fuel requirements fuel needed to evaporate 30+% slurry water • Dry process kilns less fuel requirements • Preheater/Precalciner further enhance fuel efficiency allow for high production rates 17Dry mix mortar production line reserve tanks are mainly used for storing material Normally, its capacity is 60 cubic meters, It is used to store materials such as cement, fly ash and sand, etc According to clients requirement, conveying the cement, fly ash and sand into batching scale, and then the matching material will be conveyed to the Dry Mi es For Building Production LinesFeb 05, 2021 Manufacturing of portland cement by dry and wet process pdf, Methods of cement manufacturing 1 Wet process grinding and mixing of the raw materials in the existence of water 2 Dry process grinding and The Wet process of cement (Mahasenan, ) Portland cement is by far the most common type of cement in Manufacturing Of Portland Cement By Dry And Wet Process

dry process cement production lowisfr

Dry process These are two different processes of manufacturing cement wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powder like substanceBoth the processes are in use and have their own advantages and disadvantagesWhile in wet process grinding is easier dry methods of production cement crusher export, Dry Process Cement Production Line,Cement Production Line, 116 Portland Cement Manufacturing US Environmental Protection The balance of domestic Cement Go to Product Center Cement Dry Process , This new type dry process cement production line is a kind production of cement by dry processCement is an important construction materials, it has widely used in construction industry and plays an important role for the social and economic development According the application, cement can be divided into cement and special cement General, cement according to the the main water rigid material name is divided into portland cement, aluminum acid salt cement, Cement Production Process

Cement Production Process Dry Process28crushingf

Cement Production Process Dry Process28crushingf Dry process 1 Mixing of raw material in a dry state in blenders 2 The dry materials exiting the mill are called kiln feed 3 Size of the kiln needed for the manufacturing of cement is smaller 4 Difficult to control mixing of Raw materials so it is difficult to obtain a better homogeneous materialMay 21, 2021 DETAILED DRY PROCESS OF CEMENT MANUFACTURING LCET ED In dry and semidry processes for the manufacture of cement, raw materials are crushed and fed into the grinder in the correct proportions The DETAILED DRY PROCESS OF CEMENT Cement is an important construction materials, it has widely used in construction industry and plays an important role for the social and economic development According the application, cement can be divided into cement and special cement General, cement according to the the main water rigid material name is divided into portland cement, aluminum acid salt cement, Cement Production Process

dry process cement production lowisfr

Dry process These are two different processes of manufacturing cement wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powder like substanceBoth the processes are in use and have their own advantages and disadvantagesWhile in wet process grinding is easier Dry Process for Manufacturing of Cement GharPedia The total consumption of coal in this method is only about 100 kg when compared to the requirement of about 220 kg for producing a ton of cement in the wet process The dry material undergoes a series of chemical reactions in the hottest part of the kiln and some 20 to 30 percent of the material dry process of cement sugarcubehotelThe cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry is inside the plant area and a clays quarry is as far from the plant area Manufacturing process Lafarge Cement, concrete

New Type Dry Process Cement Production Line

This new type dry process cement production line is a kind of process mainly used for small, medium and largescale cement plants Its preheater employs outside kiln precalciner Capable of utilizing the waste heat from kiln inlet to decompose raw View the interactive animation of the cement production process to learn how cement is made by CEMEX 1 Mining the raw material Limestone and clay are blasted from rock quarries by boring the rock and setting off explosives with a negligible impact of the environment, due to the modern technology employed 2Cement Production: How Cement Is Manufactured CEMEX UKfor cement production by either the dry or wet process is expressed in (3) and (4) as given in [8]: Total weight of product output per kg i i Et MJ EI (3) Total weight of product tt tt EMJ EI kg (4) where i and tt are the sums of energy inputs per unit operation and sum of energy inputs for all operations respectively Et E 3Energy and Cost Analysis of Cement Production Using the

Dry Process Cement Production Line lvssn

Dry Process Cement Production Line Capacity: 300 t/d8000 t/d Type: new dry process Materials: Limestone Clay Gypsum etc Equipment: Cement MillCement KilnBag Filter Compared with other production lines the power consumption rate of the new dry process cement production line is about 20%35% which greatly reduces the production cost for customers Ask anything about dry process of cement manufacturing ppt including ppt,pdf,doc,researches difference between sinter Go to Product Center cement process wet and dry, This page is provide professional cement process wet and dry information for you, we have livechat to answer you cement process wet and dry question here Go to Product pdf difference between dry process and wet process in cementii Cement and Lime Manufacturing Industries At present about 78 of Europes cement production is from dry process kilns a further 16 of production is accounted for by semidry and Get Price; Cement Manufacturing Process Civil EngineeringManufacturing Of Cement By Dry Process Ppt Solution For Ore

types and manufacturing of cement SlideShare

Jan 28, 2017 THE CEMENT MANUFACTURING PROCESS 1GRINDING : The clinker and the gypsum are very finely ground giving a “pure cement” Other secondary additives and cementitious materials can also be added to make a blended cement 1 GRINDING Grinding, storage, packing, dispatch 2 STORAGE, PACKING, DISPATCH 2