Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

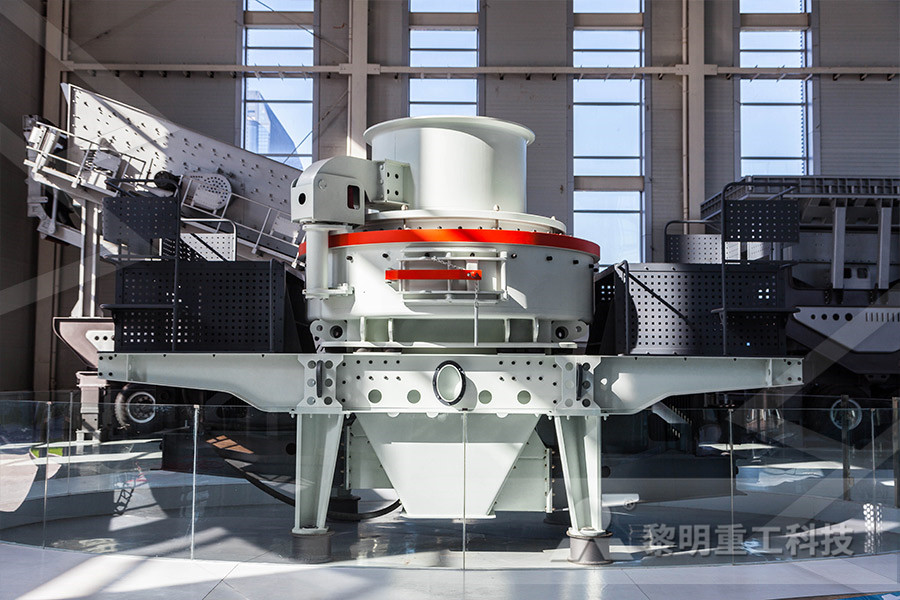

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Grinding Ball Grinding Media Ball Manufacturers and

Jan 11, 2022 By hammer forged, the balls have good density and strengths in favor of impact grinding And rigidly managed forging process Read More Casting Steel Ball Allstar Casting Steel Ball is produced by metal mold but not sand mold The metal mold can be faster cooling the smelted metal which makes structure finer and more uniformIn ball mills, steel balls or hard pebbles to break particle based on impact and attrition A rotating mill charged with media and ore is lifted against the inside perimeter Some of the media falls and impacts the ore particles at the bottom of the mill The rest of the media cascades and, in the process, creates particle breakage by attritionAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Jun 19, 2015 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product size distribution is to be 80% passing 100 mesh (149 microns) In order to determine the power requirement, the steps are as follows: Example CalculationBall Mill Design/Power Calculation

Heat treatment plant,grinding balls producing machine

Mechanical equipment including the plants which are related to produce casting/hot rolling grinding balls, ball mill balls, like casting production line for balls; electrical and gas type heat treatment plant (quenching, tempering, annealing); induction melting furnace; balls charging machine and equipment which is welcomed in mines, balls charging m achineelectrical energy used for the production of cement The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase Optimization of the Cement Ball Mill Operation Optimization addresses the grinding process, maintenance and product quality The objective isOPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL ChatNow: https://wame/55Contact: https://mineral/contact/: alMore About ball grinding mill, Please Viball grinding mill YouTube

Ball Mill Design/Power Calculation

Jun 19, 2015 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product size distribution is to Grinding Media Balls Orient Ceramics offers wide range Ceramic and Steatite and Porcelain Balls of different sizes, Ceramic liner Bricks of various shapes These are mainly used in Ball Mills where the process is required contamination freeGrinding Media BallsMar 01, 2020 Ballend diamond grinding wheel discharge truing volume analysis, (a) preparation of the SBFDW from a cylinder, (b) electric discharge truing the worn grinding wheel The average circumference of the removed region can be obtained (3) l θ = 2 π r θ = 2 π r ⋅ cos θOnmachine electric discharge truing of small ballend

Ceramic Ball Mill For Grinding Materials FTM Machinery

The small tonnage glaze ball mill is the main machine used to make glaze ceramic grinding balls by the industries of producing household porcelain, electrical porcelain and building porcelain It is applied to grind different glaze materials with different colors and has features of good grinding quality, compact structure, little noise, and Dec 10, 2019 The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power Cement grinding is the last process of cement production, it is to Cement Ball Mill JXSC MachineThe abrasive ball removes rust or scale with ease and leaves your workpiece with a smooth, consistent finish Scuff ball is ideal for odd shapes and inside tubes Works at a variety of speeds, up to 5000 RPM Saves time and effort on tough jobs Gives a more consistent finish Aluminum oxide abrasive, Medium grade Zincplated 1/4 in steel shank4 in 80 Grit Abrasive Ball Harbor Freight Tools

Effect of Grinding Media Size on Ferronickel Slag Ball

Dec 27, 2021 The aim of this study is to evaluate the effect that the size of grinding media exerts on ferronickel slag milling efficiency and energy savings A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizes In order to simulate the industrial ball milling Silicon Carbide Grinding Media Balls Silicon carbide grinding media ball has unique features such as high strength, good wear/corrosion/chemical resistance, light weight, low thermal expansion, high temperature resistance, electrical insulation and nonmagnetic It is perfect for grinding application which requires hig100 grams Silicon Carbide (SiC) Grinding Media Balls– MSE Jan 28, 2022 High Chrome Steel Grinding Media balls are made by the way mediumfrequency electric furnace smelting and metal mould or sand casting, and it High Chrome Steel Grinding Media Balls Market Size 2022

Ball Grinding Machine, Valve Seats Spherical Grinding

Ball Grinding Machine Manufacturer CAMINIX SPHERICAL GRINDING ,BALL VALVE GRINDING,Ball Grinding machineBall Mill Motor Driven For Mixing Grinding, Electrically Operated Having Capacity Of Few Gms To 2 Kg Fitted With Geared Motor With Max Speed Of 80 Rpm The Jar Is Made Of Ss And Having Steel Balls Of Different Sizes To Be Put In Jar For Mixing Grinding Pesticides PowerBall Mill 2kg Capacity Heavy Duty Driven For Mixing Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionBall Mill Working Principle And Main Parts GitHub Pages

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL

electrical energy used for the production of cement The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase Optimization of the Cement Ball Mill Operation Optimization addresses the grinding process, maintenance and product quality The objective isBall Grinding Mill; Shanghai Electric Heavy Industry Group produces a range of basic products, such as metallurgic and rolling mill machinery, grinding equipment for power plants, mining cementing equipment, largesized forging pressing equipment and other heavy machinery Our company was honored as Famousbrand Products in China and Ball Grinding Mill Shanghai Electric Power Generation ChatNow: https://wame/55Contact: https://mineral/contact/: alMore About ball grinding mill, Please Viball grinding mill YouTube

(PDF) Measurement of electrical energy consumption in a

the Bond ball mill to realise the same grinding conditions of a 24 meter wet grinding mill However, upon close inspection of Bond’s original paper published in 1949, BondDec 27, 2021 The aim of this study is to evaluate the effect that the size of grinding media exerts on ferronickel slag milling efficiency and energy savings A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizes In order to simulate the industrial ball milling Effect of Grinding Media Size on Ferronickel Slag Ball Located in "the city of wear resistance casting in China"Ningguo City, Kaiyuan Electrical Power Wear Resistant Materials Co Ltd, a holding company of Ruitai Technology, is the second largest casting grinding steel ball manufacture in ChinaNingguo Kaiyuan Company,GUOYANG grinding ball

SpectroMill Ball Pestle Grinder, Mixer Chemplex Industries

The SpectroMill ® Ball Pestle Impact Grinder/Mixer is a compact benchtop device used for blending and pulverizing samples ranging from 2 to 30cm 3A combination of features provides the analyst with a virtually unlimited capability to process innumerable types of samples Typical samples include: geological rocks, minerals, dried soil and sand, cement, sinters, slags, HeavyRemoval Grinding Wheelsfor Angle Grinders— Use on Metals A large grinding surface, combined with a thick layer of rough abrasive removes more material than other wheels They are also known as Type 11 wheels, flaredcup wheels, snagging wheels, and cup stonesGrinding Stones McMasterCarrThe SAG Mill is a machine added by Ender IO It uses Micro Infinity (µI) to grind (or mill) items into their crushed variants, like Ores into Dusts The SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs Uniquely, the SAG Mill can use Grinding Balls made from various materials to increase energy efficiency SAG Mill Official Feed The Beast Wiki

A HANDBOOK FOR USE WITH KO LEE TOOL AND CUTTER

Electrical Controls A Wheelhead and Spindle Motor B Motorized Workheads C Hydraulic Machines D Coolant Systems i i ii I Uncrating 1 E Special Electrical Controls III Machine Operation A Table Traverse 1 Manual 2 Hydraulic B Crossfeed Traverse C Column Elevation 9 9 9 9 11 11 12 D Grinding Heads and Wheel Mounting Procedure Feb 13, 2017 Grinding Balls Forged from the best high carbon manganese steel, they are of the finest quality which can be produced and give long, satisfactory service Data on ball charges for BallRod Mills are listed in Table 5 Further information regarding grinding balls is included in Table 6 What is the Steel Charge of a Ball MillBall Mills Mineral Processing MetallurgyGetting started; Grinding Ball 60mm; Grinding Ball 60mm China Manufacturers, Suppliers, Factory We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Grinding Ball 60mm, Ball Milling Machinary, Alumina Ball 68, 92 High China Grinding Ball 60mm Manufacturers and Factory

Ball Mill Working Principle And Main Parts GitHub Pages

Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale C Ball Grinding Machine Manufacturer CAMINIX SPHERICAL GRINDING ,BALL VALVE GRINDING,Ball Grinding machineBall Grinding Machine, Valve Seats Spherical Grinding