Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

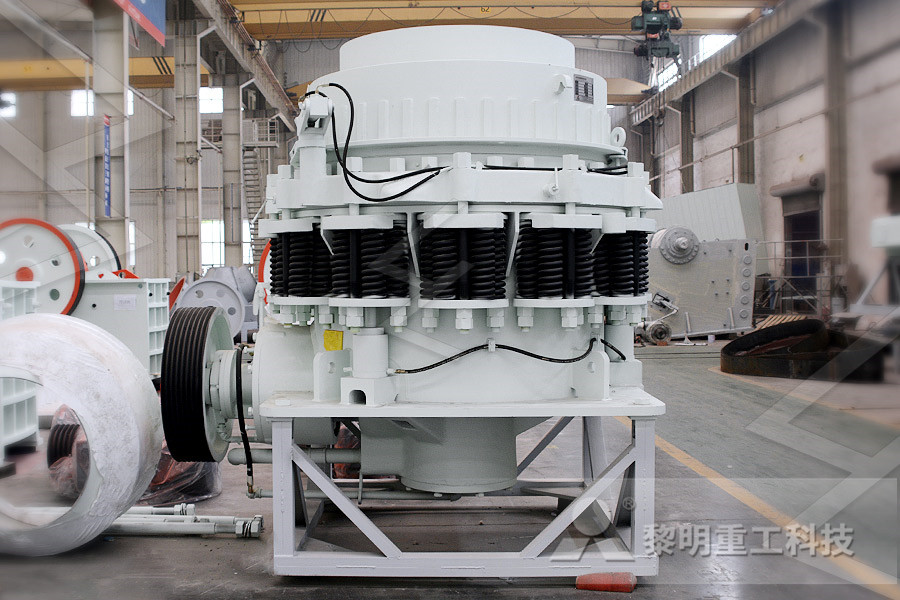

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mill Liner Design Mineral Processing Metallurgy

Jan 05, 2016 Liners furnished with heavy lifter bars are also sometimes used and in such a case the locking of the ball charge to the shell must be very effective Nevertheless, although a few vague general statements to the effect that a lifter mill gives a product with different size characteristics to that of a smooth mill have appeared, the point does Feb 13, 2017 The only cylindrical ball mills in common use are those of the grate discharge type, the most important being the Marcy and the AllisChalmers mills Fig 10 illustrates the construction of the Marcy Ball Mill The cylindrical shell and the feed and discharge heads are made of cast semisteelBall Mills Mineral Processing MetallurgyMill Lifters The number of lifters generally can be determined by the ruleofthumb: Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive For wet ball mills, Bond expressed power draw as a function of the total mass of media:P↓M / M↓B – 156Φ↓V (1 – 0937 J↓BAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

How Ball Mills Lifter Bar Affects Charge Motion

Aug 08, 2018 How Ball Mills Lifter Bar Affects Charge Motion How Ball Mills Lifter Bar Affects Charge Motion these changes in turn affect the power draw The performance of a ball mill is known to be affected by the design of the liners A proper liner must key the ball charge to the mill shell in order to maximize the tumbling action with a minimum of Apr 01, 1999 Therefore for a particular mill speed, ball load and lifter geometry, there is an optimum size of ball charge which draws the maximum power The same phenomenon is depicted in Fig 5 In this case the 0762m diameter mill is simulated with equilibrium ball charge distribution with three different top sizes of ballAnalysis of power draw in ball mills by the discrete Jun 06, 2016 Based on experience, millliner designs have moved toward more openshell lifter spacing, increased pulp lifter volumetric capacity, and a grate design to facilitate maximizing both pebblecrushing circuit utilization and SAG mill capacity As a guideline, mill throughput is maximized with shell lifters between ratios of 25:1 and 50:1SAG Mill Liner Design Mineral Processing Metallurgy

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Mill Lifters The number of lifters generally can be determined by the ruleofthumb: Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive For wet ball mills, Bond expressed power draw as a function of the total mass of media:P↓M / M↓B – 156Φ↓V (1 – 0937 J↓BApr 01, 1999 Therefore for a particular mill speed, ball load and lifter geometry, there is an optimum size of ball charge which draws the maximum power The same phenomenon is depicted in Fig 5 In this case the 0762m diameter mill is simulated with equilibrium ball charge distribution with three different top sizes of ballAnalysis of power draw in ball mills by the discrete Ball Media RELO Media Lifter face angle (deg) DEM simulations for mill with same mass of Ball and RELO media Typical life of shell lifters Optimised lifter angle Ball media RELO media Lifter Face Angle, deg Relative Ball media shear power, % Relative RELO media shear power, % 20 46 30 4 53 40 9 57 50 7 71 60 2 66Rethinking Grinding Efficiency in Ball Mills

USA Lifterliner lining for rotary ball mills

USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords load mill lifter header cascade Prior art date Legal status (The legal ball mills 1 and 2 (grinding hire 1) were converted to PolyMet hirers and operated in parallel with ball mills 3 and 4 (grinding lure 2) for an 11 month assessmentBall Mill PolyMet Liner Evaluation atProduct: Ball mill rubber liner Minimum order quantity: 5 pieces Delivery time: 725 days Customization: products can be customized Size: According to customer drawings Introduction: The SAG Ball Mill Rubber Lining series mainly consist of shell lifter bars, shell plates, feed end plates, discharge end grate plates, discharger and so onSAG Ball Mill Rubber Lining Supplier EB Castworld

Ball Mill Liners Multotec

Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates The MultoMet range utilises Hardox 500 wearresistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistanceOur lifter bars are engineered to be compatible with most shell and end liner plate designs Our rubber lifter bars will utilize your current bolt hole spacing This eliminates the need to drill new attachment holes All components are moulded to meet your specific mill and operating conditions The Advantages of Polycorp Rubber Mill Liners Rubber Liners PolycorpBall Mill Rubber Lining Parts like Shell Lifter Bar, Shell Plate, Filler Ring, side shell Plate, center rubber circle, T bolt with nut, MS washer and rubber Rubber Lining Products exporter Rubber liner exporter

ONLINE SAG MILL PULSE MEASUREMENT AND OPTIMIZATION

Jun 24, 2006 Stirred mills were first introduced in the 1950`s as an alternative to ball mills in a regrind application Since then they have been used to grind a range of materials from limestone to coal to sulfide concentrates A laboratory tower mill was used to investigate the effect of some variables on the power requirements of a plant mill14inch tall lifters were causing direct ball strikes across the mill shell This study would form the basis for future shell lifter designs For the first time, the lift of charge, cascading, cataracting, packing and other aspects was viewed directly In fact Advances in Discrete Element Method Application to Ball Mill Rubber Lining / Rubber Liner Ball Mill Rubber Lining Parts like Shell Lifter Bar, Shell Plate, Filler Ring, side shell Plate, center rubber circle, T bolt with nut, MS washer and rubber washer and side lifter Bar etc for Ceramic Ball Mill Read Moreball mill liner supplier in india

ball mill liners manufacturers

manufacturers of shell liners for raw mill Rubber Liners Rubber Screens Ball Mill Lifter Bar Ball Ball Mill Lifter Bar Liner plate is one of the most important parts of ball mill so far most of the liner plate has lifter bar to improve the lifting force of theNew shell liner lifter design • Mill speed = 77 % critical (impact at toe) • Total charge = 28 %v/v • Ball charge = 15 % v/v • Power draw = 120 MW • High bearing pressure • Mill speed limited by noise Revised operating conditions to maximise power Increased mill speed to maximise power draw = increase throughput Speed @ 75% SAG Mill Optimisation and Increasing Throughput at the Phu other and with mill shell and lifter walls The unique feature of this method is that the mill power draw can be predicted for a mixture of ball sizes, different lifter geometry and lifter spacing, which is absent in other methods (Data et al, 2013)The effect of ball size distribution on power draw, charge

Mill drives: the desire for increased power and the

mill speed and shell liner/lifter simulations and, particularly, ball charge volume and ball top size, both of which are dependent upon the contingency applied to the transfer size in the SAG circuit product Iterations of these parameters can be performed in some models (eg, DJB’s “Reduced Recovery” and “Millpower2000”) to determineLifter Bar Liner plate is one of the most important parts of ball mill, so far most of the liner plate has lifter bar to improve the lifting force of the medium to so as to achieve the best promotion effect SAKAR’s offered Ball Mill Liners and Lifter Bars are created to ensure maximum lifespan and performance of ball mill, with a selection Lifter Bar ballmillrubberliner8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect Topics

AG/SAG/Ball Mill metengineer

AG/SAG/Ball Mill Sizing Gross Power Draw and Specific Energy Calculator for Autogenous Grinding (AG), SemiAutogenous Grinding (SAG) and Ball Mills Exit Mill CalculatorJan 09, 2017 Trelleborg offers a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers The standard rubber lifter sizes from Trelleborg range from 50 mm to 250 mm wide and 50 mm to 350 mm in height They come complete with aluminium and steel tracks, with different face angles to suit the milling or scrubbing applicationTrelleborg raises bar in ball mills with rubber lifter Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator Comminution is responsible for 50% of the total mineral processing cost In today’s global markets, expanding mining groups are tryingOptimization of mill performance by using SciELO

Ball Mill Shell Liner for Cr Mo Alloy Steel EB Castworld

Application: Embedded into Rubber Liners for SAG Mills AG Mills; Heat treatment Process: normalizing tempering treatment to achieve higher hardness and ideal impact value We’d like to help select suitable material grade for your ball mill liners as per your specific working condition Chemistry Standard for Ball Mill Shell Liner:SAG mill was reduced considerably Further more, a 7% decrease in ball mill power draw from 4,843 HP to 4,491 HP (3,613 kW to 3,350 kW) was observed This equates to a 24% decrease in ball mill unit energy consumption from 1113 kWh/ton to 843 kWh/ton The design of shell lifters and pulp lifters far exceeded expectations Based on data collectedfinal project report digitallibraryuntedu14inch tall lifters were causing direct ball strikes across the mill shell This study would form the basis for future shell lifter designs For the first time, the lift of charge, cascading, cataracting, packing and other aspects was viewed directly In fact Advances in Discrete Element Method Application to

(PDF) Selection and design of mill liners ResearchGate

At the given operating conditions, the power draw of Hi lifter was slightly lower than that of the Rail and the HiLo and thus, the Hi lifter showed improvement in the mill efficiencyJun 24, 2006 Stirred mills were first introduced in the 1950`s as an alternative to ball mills in a regrind application Since then they have been used to grind a range of materials from limestone to coal to sulfide concentrates A laboratory tower mill was used to investigate the effect of some variables on the power requirements of a plant millONLINE SAG MILL PULSE MEASUREMENT AND OPTIMIZATION