Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

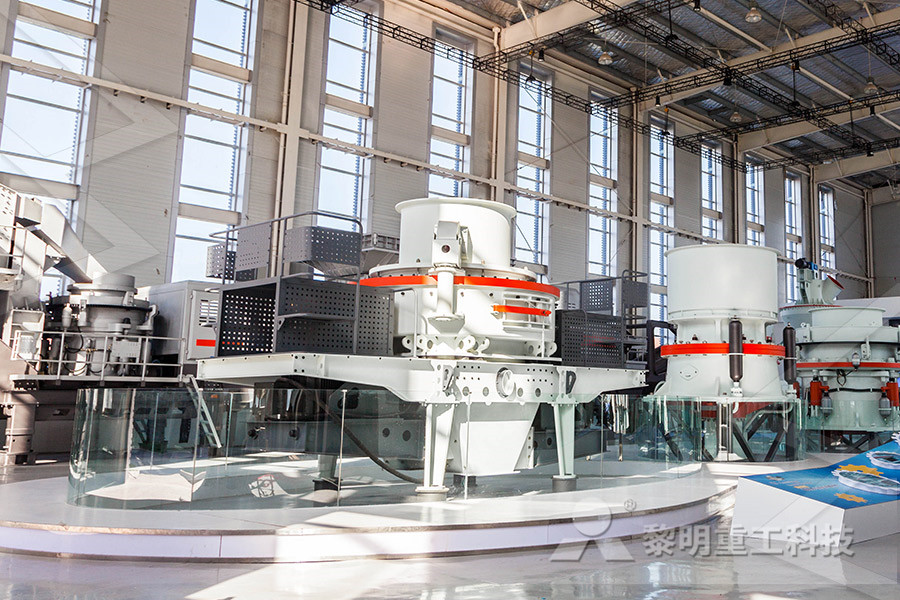

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Capacities and performance characteristics of jaw crushers

performance of jaw crushers are given in Table 2 (Hersam, 1923) For calculating the values of K2, the value of Kg for materials like granite and traprock were set equal to one, and the values of KI were calculated with Eq (10) The variation of K2 with T/G (Table 2) can be representedImprovement and Performance Evaluation of JawType Rock Crushing Machine C Ocheri, J B Agboola and C N Mbah Department of Metallurgical and Materials Engineering, University of Nigeria, Nsukka, Nigeria Examples are Jaw crusher, Gyratory crusher, Impact Crushers, etc The crushed rocks from primary crusher are sent to the secondaryPaper: NMS 2017TP002 Improvement and Performance Up to10%cash back Sep 21, 2021 The speed of the crusher is another important operating parameter (expressed in terms of the flywheel rpm) Single toggle jaw crushers can range in speed from 200 rpm to 350 rpm, and speeds do not typically fall below the 200 rpm thresholdEvaluation of blast fragmentation effects on jaw crusher

Performance Of Jaw Crushers Crusher Mills, Cone Crusher

Jaw crusher,Jaw crushers,Primary crushers,Jaw breakers,Mobile And also, Jaw crusher is always used as the Primary jaw crusher Jaw crusher’s Performance and Features 1 Crushing cavity is deep and there is no dead area, Oct 26, 2010 The prediction of crusher performance is typically concerned with the size distribution of the product exiting the crusher, the machine’s power draw, and the capacity The capacity of a jaw crusher is dependent upon the operating characteristics of the machine and influenced by the feed size and the nature of the materialJAW CRUSHER SELECTION AND PERFORMANCE PRIDICTING Sep 15, 2014 It must be at least 36 in wide for an 18 x 36 jaw crusher So a 4ft by 8ft screen would be acceptable The 1in screen is a second deck for the 38 tph from the jaw crusher, so the deck correction factor is 090 and that screen capacity is 21 x 09 = 189 tph/sq ft The screen area needed under the jaw crusher is 38/189 = 201 sq ftCrusher Efficiency Calculations

Evaluation of blast fragmentation effects on jaw crusher

Request PDF Evaluation of blast fragmentation effects on jaw crusher throughput The fragmentation rate and particle size distribution of the muckpile after The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time This is dependent on the area of the discharge opening, the properties of the rock, moisture, crusher throw, speed, nip angle, method of Jaw Crusher an overview ScienceDirect TopicsJun 01, 2020 Jaw crusher performance can be optimised for increased aggregate quality • Calculation of flakiness index hides variation of particle shape within a gradation • Mechanical properties are highly affected by sample preparation AbstractInfluence of jaw crusher parameters on the quality of

FIELD MONITORING AND PERFORMANCE

Field monitoring and performance evaluation of crushing plant operation 617 Fig 1 Typical flowsheet of crushing plant Factors affecting crusher performance Figure 2 shows a number of factors that can affect the performance in ore crushing plant However, these factors can be illustrated by three categories of influence: oreMar 30, 2020 Besides being an important item for the machine’s performance, the jaw crusher’s jaws are responsible for front frame and swing jaw protection Wear generally causes loss in production due to increased crushing angle, loss How to improve jaw crusher performance and productivity May 01, 1994 Capacities and performance characteristics of jaw crushers By using the data of EA Hersam and FC Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of industrial jaw crushers The study showed that industrial jaw crushers are generally operated below capacityCapacities and performance characteristics of jaw crushers

performance of jaw crusher worldcrushers

Jul 15, 2013 JAW CRUSHER SELECTION AND PERFORMANCE PRIDICTING – Product Jaw crushers are large, heavyduty machines capable of crushing large quantities of tough, abrasive materials They are typically employed as primary crushers within This entry was posted in Uncategorized Bookmark the permalink Dec 29, 2021 The flake rock needs a toothshaped jaw mold to crush it into more cubes to avoid stopping by bridging and belt cutting along the crushing circuit Monitor the Condition of the Jaws In addition to being an important part of machine performance, the jaw of the jaw crusher is also responsible for the protection of the front frame and the swing jawWays to Improve the Performance of Jaw CrusherThe jaw crusher machine has a fixed jaw plate and a swing jaw plate It is more conducive to crushing harder materials So that it has excellent performance of high processing capacity and low energy consumption Jaw crusher’ special crushing chamber is more economical because users could adjust its jaw plate’s position to lengthen service Jaw Crusher Machine Large Crushing Ratio and Long

jaw crusher improvem crusher performance

IMPROVING C160 C200 JAW CRUSHER PERFORMANCE IMPROVING C160 C200 JAW CRUSHER PERFORMANCE Download White Paper November 7, 2017 BHP Area C located in the Pilbara region of Western Australia, operates TON C160 and C200 jaw crushers as its primary processing plant and was experiencing excessive wear and insufficient liner lifeIn this case, the value of R 2 of jaw crusher is 9898 %, back toggle plate is 9887 %, chute liner plate is 9283 %, jaw plate is 9964 % and tie rod is 9312 % and is exposed in T able 8 (PDF) Failure analysis of jaw crusher and its components Jul 07, 2020 The mobile jaw plate of a jaw crusher is under severe impact in humid and high temperature environments In the world, there are approximately 200–300 thousand movable jaw plates damaged by wear every year, and the consumption of steel is approximately 60–72 thousand tons []Each year, this directly causes a loss of more than one billion dollars []Finite Element Study on the Wear Performance of MDPI

FIELD MONITORING AND PERFORMANCE EVALUATION OF

Field monitoring and performance evaluation of crushing plant operation 617 Fig 1 Typical flowsheet of crushing plant Factors affecting crusher performance Figure 2 shows a number of factors that can affect the performance in ore crushing plant However, these factors can be illustrated by three categories of influence: oreAug 14, 2020 Simulations of the jaw crusher incorporating a description of particle breakage can be a useful tool in design and optimization of the machine, since DEM may be an excellent tool to predict machine performance, including assessing measures that are hard to obtain experimentally, such as the stress gradient on the jaw platesDEM Simulation of LaboratoryScale Jaw Crushing of MDPISep 06, 2017 This paper presents the results of laboratory tests and evaluation of influence of crushing plates shape on rock crushing process performed on doubletoggle jaw crusher Machine is equipped with diagnostic system that monitors operation of the crusherEvaluation of Influence of Crushing Plates Shape on

Morphological characteristics of mineral filler and their

The coating ratios were calculated by image analysis and volumetric analysis, used to represent the active adhesion properties The results show that the roundness of jawcrushed filler is the smallest, and it can be attributed to the heavier force of 3) LITERATURE: Crushers are slow speed machines for coarse reductions and can break large lumps of various hard materials as in the primary and secondary reduction of rocks and ores In a jaw crusher, the feed is admitted between the two jaws, said to form vopen at the top One jaw is fixed and the other is movable It makes an angle of 200 300 with the fixed jaw (2)mechopsreportdocxpdf \u201cDROP WEIGHT CRUSHER AND Feb 02, 2021 (4) The proposed aggregate performance evaluation index CEI is integrated into the aggregate shape recognition system CAMIS, and the parameters of S3 jaw aggregate crusher are optimized The combination of processing parameters is recommended as rotational speed: 45 m/s feed: 3 t/h air intake: 30%Frontiers Study on Quantitative Characterization of

Factors affecting the performance of jaw crusher HYSAN

Apr 10, 2020 However, with the increasing number of jaw crusher manufacturers on the market, the performance of jaw crushers on the market is also uneven, and how to choose a costeffective machine has become a problem Jaw The reduction ratio of jaw crusher is 3:1 to 5:1 This paper focuses on review of a work done by researchers in the field of kinematic and dynamic analysis of jaw crusher attachments Kinematic and dynamic analysis is very useful to understand and improve the quality of jaw crushers Keywords–Jaw crusher, Kinematic analysis, Dynamic analysisStudy of Kinematic and Dynamic Analysis of Jaw Crusher A the characteristics and performance of jaw crusher – Vanguard QA what is the performance characteristic of jaw crusher? asked 4 days ago in Business by jewdore (2,070 points) crusher; grinding; mill; gold; copper–1 vote 0 answersWhat Are The Performance Fo Jaw Crusher ? Crusher Mills

5 Feeding Techniques to Improve Jaw Crusher Performance

5 Feeding Techniques to Improve Jaw Crusher Performance Jaw crusher is the primary crushing equipment of the whole gravel production line, and its efficiency has a great influence on the production line Feeding is the first step in crushing and making sand, and mastering certain feeding skills will help improve the productivity and efficiency Apr 16, 2021 Jaw crusher is mainly composed of a fixed jaw plate, movable jaw plate, frame, upper and lower guard plates, adjusting the seat, movable jaw rod, and so on The ore materials to be crushed enter the crushing chamber from the upper feed inlet, and the movable jaw plate periodically reciprocates the fixed jaw plate around the eccentric shaft, and sometimes PE Jaw Crusher Plant High Quality and Good Performance Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed element (bowl liner) (PDF) A performance model for impact crushers

New Generation Vanguard Jaw Crusher Reduces Maintenance

Sep 16, 2013 “With the increased energy and performance, producers can expect the Vanguard Jaw Crusher to deliver up to 25 percent more tons per hour than comparable jaw crushers,” Griess said Components such as the common flinger collar, stressrelieved base frame and machined saddle work together to increase the lifespan of the machinePerformance Evaluation of a Locally Fabricated Crusher (Hammer Mill) A bonecrusher ( Haminrrer Mill ) was designed, constructed and tested The machine was designed to crush 1000kg of bones in one hour The motor operating speed employed is 2920rpm, the sieve hole diameters are 7mm and 5mm while the numbers of hammers are 12 and 18 'piecesPerformance Evaluation of a Locally Fabricated Crusher 3) LITERATURE: Crushers are slow speed machines for coarse reductions and can break large lumps of various hard materials as in the primary and secondary reduction of rocks and ores In a jaw crusher, the feed is admitted between the two jaws, said to form vopen at the top One jaw is fixed and the other is movable It makes an angle of 200 300 with the fixed jaw (2)mechopsreportdocxpdf \u201cDROP WEIGHT CRUSHER AND

roll crushers and sto performance

Roll Crusher With stable Performance Fote Machinery(FTM) Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch Roll crushers can adjust the wedge device between rollers to control the feed and discharge size of 2021 New Type Low Price Jaw Crusher Plant 10200 Tph Stone Crushing Line With High Quality Image Results Crushing Line, Stone Crushing Line, Rock Crushing Line manufacturer / supplier in China, offering High Performance Crushing Line with Capacity 30800 Tph, Pew760 Limestone Jaw Crusher with High Quality, Small Portable Rock Jaw Crusher High Performance Jaw Crusher 600X300 with CE Crushers HiTech provides Finite Element Analysis (FEA) services for industrial crushers like Jaw, gyratory, impact and autogenous Crushers Our FEA simulations provide indepth performance evaluation of crushers by considering factors such as loads resulting due to cyclic vibrations from rotating motors, gravity load, mechanical loads due to crushing operation and Crushers FEA Analysis, Crusher Vibration and Fatigue Analysis

perfomance evaluation on doble roll crusher Romania

Thu Double Rolls Tooth Rolls Crusher Trinity Trade Perfomance Evaluation On Doble Roll Crusher Logicommercenl They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 61 reduction ratio in the primary stage and a 41 Stone crushers, Jaw, Cone, Impact, Vsi crusher for What is uncrushed aggregrate As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, What is uncrushed aggregrate, quarry, aggregate, and different kinds of mineralsWhat is uncrushed aggregrate