Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

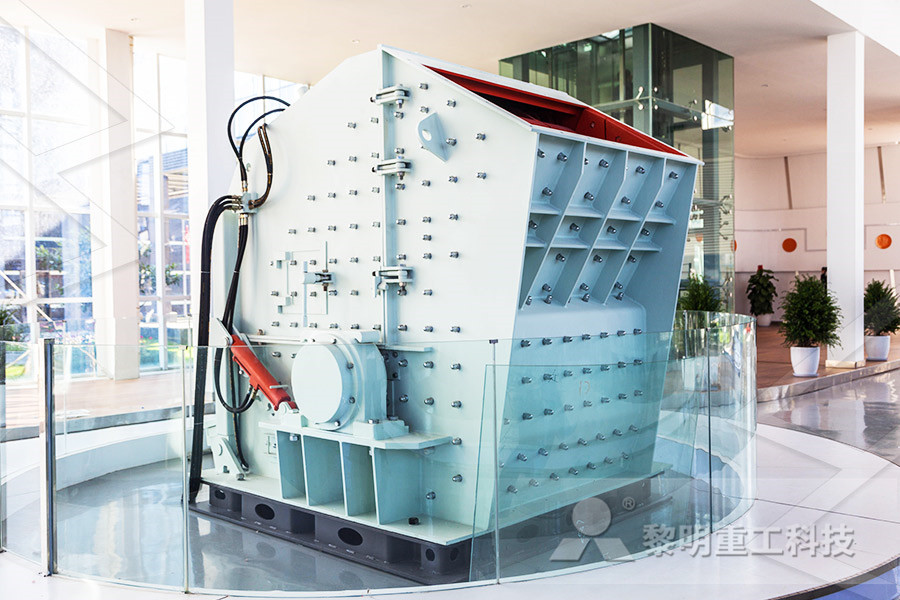

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Direct VS IndirectFired Rotary Kilns Dryers

In a directfired rotary kiln, the heat source is hot gas (products of combustion and air) which flows with an inherent velocity These gases can carry discrete particles through from drag The degree of entrainment depends on a variety of factors such as gas velocity, gas density, particle density, and shapeDirect fired rotary kilns are refractory lined cylinders arranged with a refractory lined breeching on one end with a gasfired burner that fires down the centerline of the cylinder The kiln can be arranged for parallel flow or counterflow heatingRotary Kilns Thermal Processing Solutions, IncRotary Kilns Direct Fired Rotary Kilns Direct Fired Rotary Kiln is fuel fired, refractory lined Rotary Kiln Indirect Fired Rotary Kilns Indirect Fired Rotary Kiln with refractory lined Furnace Chamber Continuous Rotary Dryer/Calciner Fuel Fired up to 1200°C Client: Sudarshan Chemical Industries LtdRotary Kilns Direct Fired Rotary Kilns Indirect Fired

IBUtec The Rotary Kiln Experts for Trials and Production

In a directfired rotary kiln, the burner is situated inside the kiln body, that is, inside the reaction chamber The material is heated directly by the burner flame and the stream of hot gas produced by the burner These kilns are usually lined with refractory (heatresistant) material so that they can be operated at higher temperatures than Dec 01, 1978 Up to10%cash back The characterization of heat flow processes in directfired rotary kilns requires detailed measurements of gas, solids and wall temperatures This paper describes the construction, instrumentation and operation of a 55 m long x 0406 m inside diam kiln designed for such measurements The heating of inert sand was chosen for Heat transfer in a directfired rotary kiln: I Pilot A directfired rotary kiln heats material by passing the combustion gases through the rotary kiln The combustion can either occur in a com bustion chamber if direct flame radiation is to be avoided, or the flame can be directed down the length of the rotary kilnROTARY KILNS Thomasnet

Rotary Kiln an overview ScienceDirect Topics

There are two types of rotary kilns, ie, direct fire and indirect fire The direct fire is a single shell vessel with rings added inside to slow the catalyst as it tumbles from the inlet (elevated part) towards outlet (lower part) The oxidation medium flows countercurrent to catalyst movementA variety of drive assembly Rotary kilns are used to heat solids to the point where a chemical reaction or physical change takes place arrangements are available: chain and sprocket, gear They work by holding the material to be processed at (PDF) Rotary Kiln Handbook NEW Ahmad Reza Jamali Direct Fired Rotary Kilns Direct Fired Rotary Kiln is fuel fired, refractory lined Rotary Kiln Temperature Range 100°C to 1500°C Heating Media Liquid fuel / Gaseous Fuel Purpose Roasting, Calcination, Reduction, Sintering, High Temperature Reactions, Preheating CapacityRotary Kilns Direct Fired Rotary Kilns Indirect Fired

Feeco Equipment Thermal Processing DirectFired

Feeco DirectFired Rotary Kilns FEECO is a leading manufacturer of highly engineered, custom rotary kilns for processing solids Our high temperature kilns have earned a reputation for their durability, efficiency, and longevity We offer both direct and indirectfired unitsThe overall heattransfer mechanism within a directfired rotary kiln has been examined theoretically To accomplish this task, the work has been divided into three parts: (1) the characterization of radiative heat transfer within the freeboard area; (2) the overall heat transfer mechanism in the absence of freeboard flames; and, (3) the overall heat transfer mechanism Heat transfer in directfired rotary kilns UBC Library BartlettSnow™ directfired rotary kilns are provided for applications requiring product temperatures to 3000°F / 1650°C and oxidizing or slightly reducing atmospheric conditions In addition, the process material must tolerate contact with products of combustion and/or the burner flame envelope, as well as reflect a particle size range Bartlett Snow™ Rotary Kilns for high temperature applications

Rotary Kiln IspatGuru

Dec 26, 2019 Directfired rotary kilns are the most common for this application, since air is needed to burn the organics Sintering/induration – Sintering is the process of heating the raw materials to a point just before melting The objective of this process is to use the high internal temperature of the rotary kiln to increase the strength of the Heat flow rates from the gas to the wall and to the bed have been derived from temperature profiles measured in the UBC pilot rotary kiln The experimental gastowall heat flux has been found to agree closely with theoretical predictions based on a simple radiative model consisting of a grey gas surrounded by a grey surface at uniform temperatureHeat transfer in a directfired rotary kiln: II Heat flow stream In order to expand the applicability of directfired rotary kiln systems to additional remediation opportunities, the low temperature treatment effectiveness of rotary kiln units must be evaluated APPROACH The use of low temperature thermal desorption is an attractive alternative to high temperature incineration for someLow Temperature Desorption Applications of a Direct

Rotary Kiln Manufacturers in India: Rotary Calcination

In directfired kilns, the material is directly in contact with the process gas Indirect fired kilns are used for applications where the processing occurs in an inert atmosphere or when the material has to be controlled It is refractory lined because of the high amount of heat is IndirectFired Kilns Directired rotary kilns are most often the equipment Conversely, indirectired kilns can process material in of choice in thermal processing, because they are an inert environment, where the material never comes more eficient than their indirect counterparts(PDF) Rotary Kiln Handbook NEW Ahmad Reza Jamali Direct Fired Systems Systems, based on the proven Wellons cell furnace, are available with ratings up to 250 MM BTU/Hr gross heat output Typical system configurations supply up to four rotary dryers through hightemperature, insulated, refractorylined, steelcased ducts High temperature gases are also ducted through a wellons designed and Direct Fired Systems Wellons

Coal based Direct Reduction Rotary Kiln Process IspatGuru

Feb 14, 2017 Normally for rotary kiln process volatile matter is to be in the range of 25 % to 30 % Coals for direct reduction in the rotary kiln need to have low swelling index Normally swelling index is to be less than 1 The physical and chemical specifications of the noncoking coal are as follows Size of lumps – 5 mm to 20 mmRotary kilns can be either of the directfired type, or the indirectfired type (sometimes referred to as a calciner) In a directfired kiln, a process gas is fed through the drum, processing the material via direct contactRotaryKilnHandbookNEWpdf THE ROTARY KILN HANDBOOK Aug 21, 2020 Rotary Kiln Refractory Lining and Fire Bricks Protective Measures April 27, 2021 August 21, 2020 The main function of the rotary kiln refractory lining is to protect the barrel of the rotary kiln from hightemperature gas and hightemperature materials and to ensure normal production According to the different types of calcined materials Rotary Kiln Refractory Lining and Fire Bricks Protective

Rotary Kilns Calciners Nelson Machinery Equipment Ltd

Nelson Machinery sells rotary kilns, direct fired kilns, drying kilns, rotary calciners, indirect fired calciners Equip yourself with the gold standardFeeco DirectFired Rotary Kilns FEECO is a leading manufacturer of highly engineered, custom rotary kilns for processing solids Our high temperature kilns have earned a reputation for their durability, efficiency, and longevity We offer both direct and indirectfired unitsFeeco Equipment Thermal Processing DirectFired The overall heattransfer mechanism within a directfired rotary kiln has been examined theoretically To accomplish this task, the work has been divided into three parts: (1) the characterization of radiative heat transfer within the freeboard area; (2) the overall heat transfer mechanism in the absence of freeboard flames; and, (3) the overall heat transfer mechanism Heat transfer in directfired rotary kilns UBC Library

Rotary Kiln IspatGuru

Dec 26, 2019 Directfired rotary kilns are the most common for this application, since air is needed to burn the organics Sintering/induration – Sintering is the process of heating the raw materials to a point just before melting The objective of this process is to use the high internal temperature of the rotary kiln to increase the strength of the stream In order to expand the applicability of directfired rotary kiln systems to additional remediation opportunities, the low temperature treatment effectiveness of rotary kiln units must be evaluated APPROACH The use of low temperature thermal desorption is an attractive alternative to high temperature incineration for someLow Temperature Desorption Applications of a Direct Under normal conditions, the heat source of indirect fired rotary kilns is supplied from the kiln burner outside the kiln This kind of way protects the integrity of raw materials, while the heat source of the directfired rotary kiln is inside the kiln Besides, the rotation speed and temperature of the cylinder are tightly controlled and Cement Rotary Kiln Rotary Kiln Rotary Kiln

rotary dryer manufacturers in Mumbai, rotary dryer

Rotary Kilns / Calciner – Direct Fired Aswathi Industries Limited (AIL) has proven to be one of the leading manufacturers and suppliers of Rotary Kilns for numerous industries for decades now AIL offers a wide range of kilns having superior quality, extensive workability, long service life and resistance against corrosionDirect Fired Rotary Kilns Rotary kilns are used for hightemperature thermal processing of mineral concentrates Rotary kilns are designed with specific refractory linings to suit the process requirements Kiln burners are tailor design through a partner company to specifically meet the process requirements Rotary kilns have specific sizes Direct Fired Rotary Kilns DryTech InternationalWe must therefore get energy into the process as well as extract energy This chapter examines the energy source and supply required to sustain the operation for which the dominant source is fossil fuel combustion Herein, the basics of combustion and the flame that develops and forms the heart of the directfired rotary kiln are presentedRotary Kilns ScienceDirect

Coal based Direct Reduction Rotary Kiln Process IspatGuru

Feb 14, 2017 Normally for rotary kiln process volatile matter is to be in the range of 25 % to 30 % Coals for direct reduction in the rotary kiln need to have low swelling index Normally swelling index is to be less than 1 The physical and chemical specifications of the noncoking coal are as follows Size of lumps – 5 mm to 20 mmVulcan Drying Systems Indirect Fired Rotary Dryer IDR 8435 Series Manufacturer: Vulcan Drying Systems Vulcan Drying Systems Indirect Rotary Dryers rely on the heat transferred through the drum’s shell to dry the material via conduction and radiation to reduce the material’s moisture content Indirect drying allowUsed Used Rotary Kilns for sale Barker equipment more Direct fired rotary kiln incineration is proven to be the best available technique for small medium scale waste disposal requirements It has a good thermal treatment solution for safe and effective destruction of heterogeneous and difficult to handle wastesRotary Kiln TAKFA

(PDF) HEAT TRANSFER IN ROTARY KILN FROM DEVA CEMENT FACTORY

Brimacombe, Watkinson, Heat Transfer in a direct fired rotary kiln: I1 Heat flow results and their interpretation, Metallurgical Transactions B, Vol 9B June 1978General layout of a direct fired countercurrent rotary kiln used in cement manufacture Rotary kiln body, with drive gear and 2 tyres (riding rings) A rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process Materials produced using rotary kilns include:Rotary kiln WikipediaUsed Rotary Kilns EquipNet is the leading global provider of preowned equipment, including used rotary kilns and much more Our exclusive contracts with our clients yield a wide range of used rotary kilns from a number of respected OEMs, including Unknown manufacturers and others We are constantly receiving used rotary kilns in a range of Used Rotary Kilns Buy Sell EquipNet