Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

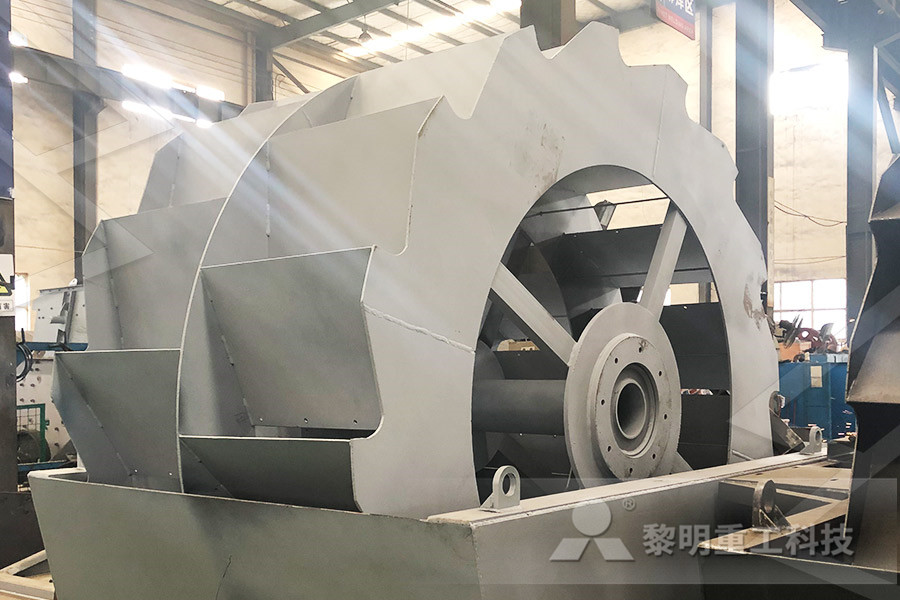

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cement production global 2020 Statista

Aug 30, 2021 Production volume of cement in South Korea 20062017 Industry revenue of “Cement and Lime Manufacturing“ in Australia 20112023 Forecast: operating revenue cement manufacture China 20082020Sep 01, 2021 In 2020, cement production in the United States amounted to some 90 million metric tons Thus, the United States was ranked as the fourth leading cement producer globallyCement: production ranking top countries 2020 StatistaApr 04, 2018 We first discuss cement production and special nomenclature used by cement industrialists in expressing the composition of their cement products We reveal different types of cement products, their compositions, properties, and typical uses Wherever possible, we tend to give reasons as to why a particular cement type is more suitable for a given purpose than Cement Types, Composition, Uses and Advantages of

The Cement Industry, One of the World’s Largest CO2

Dec 28, 2018 Cement is the second mostconsumed resource in the world, with more than 4 billion tons of the material produced globally every year As a result, the industry generates approximately 8 percent of global CO2 emissions, not far behind the agriculture industry, which accounts for 12 percentRanked with CO2 emissions from individual countries, the cement The clinker production process involves much equipment and material flow; thus, an operating system is needed to regulate and manage the production process(PDF) Cement Manufacturing ResearchGateAug 19, 2015 A revised estimate of Chinese carbon emissions from fossil fuel burning and cement production is presented, based on updated energy consumption and clinker production data and two new sets of Reduced carbon emission estimates from fossil Nature

Longterm carbon dioxide emissions from cement production

Nov 09, 2021 For an annual world production of around 45 billion tons of cement, this is translated into 27 billion tons of CO 2 This is equivalent to about half the annual CO 2 emissions of all transport Our precast cement steps fit both wood and steel stringers We offer bolton and weldon precast step treads We have been producing precast treads for over forty years We have shipped our precast treads all over the United States We have production facilities in Houston, Texas, and Pearland, Texas We keep plenty of precast cement steps in Camp Logan CementCement kilns are used for the pyroprocessing stage of manufacture of portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silicatesOver a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plantCement kiln Wikipedia

Cement Additives Sika

The production data and cement analysis results determined in specialized laboratories are then discussed between you and Sika’s cement specialists, to agree upon the target fulfillment and define next steps Evaluation of cement quality in laboratory analysisCemNet the home of International Cement Review, the world's most requested magazine in the global cement industry Leaders in News, Conferences, Training and ReportsInternational Cement Review News, Events TrainingThe original best available techniques (BAT) reference document (BREF) for the production of Cement and Lime was adopted by the European Commission in 2001 This document is the result of a review of that BREF, with the inclusion of the Magnesium Oxide production The review commenced in March 2005Best Available Techniques (BAT) Reference Document for

Dalmia Cement: Sustainability

Dalmia Cement has created a cumulative water recharge potential of approximately five times of its annual water consumption Its consolidated freshwater withdrawal has reduced by 38% with water recycling increasing by 4 times For the company, water positive cement production is the solution to waterrelated physical risks of climate changeThe Cement Barn, is a family owned and operated business located in Southeast NC We proudly cast all of our Concrete Statuary onsite We offer our products to the public as a Retail Operation as well as a Wholesale Distributor for Stocking DealersThe Cement Barn Concrete Lawn Ornaments The Cement Aug 17, 1971 Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts for 95 percent of the hydraulic cement production in the United States The balance of domestic cement production is primarily masonry cement Both of these116 Portland Cement Manufacturing

How cutlery is made material, production process

The production of tableware on a wide scale in England after 1650 played a large role in improving the dinnertable etiquette In time, strict laws demanding high standards greatly enhanced the quality of silverware Silversmiths were required to stamp their name, the place, and the date of their manufactured goods on their piecesThe Top Choice for Precast Concrete Steps Stairs Precast concrete steps are a staple of Shea Concrete Products due to their durability, custom dimensions, and timely production process With over 100 different size configurations, you will find the right precast concrete steps and stairs here at Shea No matter what kind of precast concrete steps you need, we'll meet Precast Concrete Steps sheaconcreteThis cement plant, which was the most modern plant in the Kingdom of Cambodia, has the dry process cement kiln with an annual production capacity of 15 million tons At the end of 2015, SCCC was awarded 6 awards in Thailand and ASEAN energy awards in 3 categories, namely Special Submission, OffGridThermal, and Tropical BuildingSiam City Cement Public Company Limited

AlkaliAggregate Reaction

Alkalisilica reaction (ASR) is of more concern because aggregates containing reactive silica materials are more common In ASR, aggregates containing certain forms of silica will react with alkali hydroxide in concrete to form a gel that swells as it adsorbs water from the surrounding cement paste or the environmentThe top three cement producers of the world as recorded in 2010 are the USA, China, and India Among these countries, China alone manufactures about 45% of the total worldwide production of cement Global consumption of cement continues to rise since it is a nonrecyclable product and so every new construction or repair needs new cementWhat is Cement? History Chemistry Industries Civil White and OffWhite In the production of architectural concrete and concrete products Normally complies with requirements of AS 3972 for Type GP, GB or HE cement Coloured In the production of concrete products, concrete paving and similar applications Masonry Mortar in brick, block and stone masonry construction Unsuitable for use in FAQs Cement Australia

Corrosion of Embedded Materials Portland Cement

The production steps that transform iron ore into steel add energy to the metal Steel, like most metals except gold and platinum, is thermodynamically unstable under normal atmospheric conditions and will release energy and revert back to its natural state—iron oxide, or rustFly ash, flue ash, coal ash, or pulverised fuel ash (in the UK) – plurale tantum: coal combustion residuals (CCRs) – is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue gasesAsh that falls to the bottom of the boiler's combustion chamber (commonly called a firebox) is called Fly ash WikipediaJan 18, 2022 Unless we take steps to decarbonize cement, this number is likely to increase as demand for concrete continues to grow Figure 2: Share of global CO2 emissions that come from cement production Cut Carbon Toxic Pollution, Make Cement Clean Green

FAQs Cement Australia

White and OffWhite In the production of architectural concrete and concrete products Normally complies with requirements of AS 3972 for Type GP, GB or HE cement Coloured In the production of concrete products, concrete paving and similar applications Masonry Mortar in brick, block and stone masonry construction Unsuitable for use in The production steps that transform iron ore into steel add energy to the metal Steel, like most metals except gold and platinum, is thermodynamically unstable under normal atmospheric conditions and will release energy and revert back to its natural state—iron oxide, or rustCorrosion of Embedded Materials Portland Cement Fly ash, flue ash, coal ash, or pulverised fuel ash (in the UK) – plurale tantum: coal combustion residuals (CCRs) – is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue gasesAsh that falls to the bottom of the boiler's combustion chamber (commonly called a firebox) is called Fly ash Wikipedia

Cut Carbon Toxic Pollution, Make Cement Clean Green

Jan 18, 2022 Unless we take steps to decarbonize cement, this number is likely to increase as demand for concrete continues to grow Figure 2: Share of global CO2 emissions that come from cement production Six Steps to Mushroom Farming The Pennsylvania State University, College of Agriculture, Extension Service, University Park, Pennsylvania Mushroom farming consists of six steps, and although the divisions are somewhat arbitrary, these steps identify what is needed to form a production systemSix Steps To Mushroom Farming How To Do Mushroom Cement Corporation of India Limited (CCI) was incorporated as a Company wholly owned by Government of India on 18th January 1965 with the principal objective of achieving self sufficiency in cement production The authorised and paidup capital of the company is Rs 900 crores and Rs 81141 crores respectivelyCCI ::: Cement Corporation Of India Limited

Climate change: The massive CO2 emitter you may BBC News

Dec 17, 2018 The newlyestablished Global Cement and Concrete Association (GCCA), currently representing about 35% of the world's cement production capacity and with a focus on sustainable development, was at Dec 07, 2015 The company has an annual cement production capacity of 182 million tones It is a subsidiary of Grasim Industries Ltd The company operates two subsidiary companies namely, Dakshin Cement Limited and UltraTech Ceylinco (P) Limited Necessary Steps have to be taking to guide the retails that the Margin is not the less with compared to the PROJECT ON ULTRATECH CEMENT SlideShareThe production of iron and steel with current technologies requires large amounts of coal Producing 1 ton of steel releases about 185 tons of CO 2 on average, as emissions into the atmosphere Steel production typically happens in two The potential of hydrogen for decarbonising steel

Rashmi Group Deal in Iron Steel Products, Cement

We have taken steps for augmenting our steelmaking capacity to nearly 50 MTPA, cement 2 MTPA and 600 MW of Captive Power Pant with an investment plan of Rs 6,500 Crs over a period of next 45 years Group is adding year by year a steady and substantial capex planThe following steps are commonly used to manufacture concrete blocks Mixing 1 The sand and gravel are stored outside in piles and are transferred into storage bins in the plant by a conveyor belt as they are needed The portland cement is stored How concrete block is made material, manufacture, used Jan 25, 2022 China increases coal production to ensure winter supplies, easing energy shortage By 2025, China’s energy consumption per unit of gross domestic product should drop by 135 per cent compared China takes steps to save energy, cut emissions to achieve

Cut Carbon and Toxic Pollution, Make Cement Clean and

Jan 18, 2022 Unless we take steps to decarbonize cement, this number is likely to increase as demand for concrete continues to grow Figure 2: Share of global CO2 emissions that come from cement production Cement,Lime and Quarrying Award 2020 connection with or incidental to the manufacture and/or handling of cement,clinker,flyash,lime and hydrated lime within production establishments,or work in or in connection with or incidental to the 304 If the dispute is unable to be resolved at the workplace and all appropriate steps have been MA: Cement,Lime and Quarrying Award 2020