Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

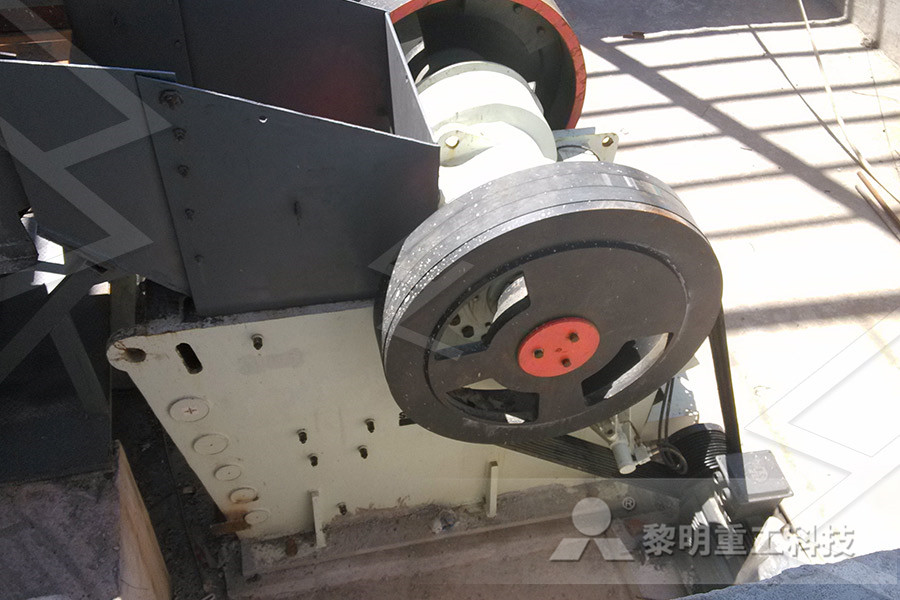

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Iron Bridge Magnetite Project, Australia Mining Technology

Nov 02, 2020 The ore will be crushed and processed at the site for the production of magnetite, dry process rejects, and wet tailings The processing plant will use dry crushing and grinding circuit The plant will employ the KB 63130 type gyratory crushers, which will be the largest crushers in the countryJul 05, 2021 42 billion tonnes (JORC 2012) of iron ore Over 110 kilometres of unexplored strike 1,520 km 2 of surrounding tenements 100% owned by Magnetite Mines Limited The Razorback High Grade Iron Ore Concentrate Project is an iron ore project in the western portion of the Braemar and is wholly owned and operated by Magnetite Mines LimitedRazorback Iron Project Magnetite MinesComminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes In geology, it occurs naturally during faulting in the upper part of the Earth's crust In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other fields, accomplished with Comminution Wikipedia

US$26 billion Iron Bridge Magnetite Project approved

US$26 billion Iron Bridge Magnetite Project approved The innovative design, including the use of a dry crushing and grinding circuit, will deliver an industryleading energy efficient operation with globally competitive • Secondary crushing/screening and coarse ore stockpiles are located part way betweenDec 27, 2021 The aim of this study is to evaluate the effect that the size of grinding media exerts on ferronickel slag milling efficiency and energy savings A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizes In order to simulate the industrial ball milling Minerals Free FullText Effect of Grinding Media Size Working principle Ball mill grinding machine is a kind of horizontal drumtype grinding mill with external gear and double bins Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different specificationsSteel balls are taken to a certain height by centrifugal force from drum rotation and then fallBall mill, mineral ball mill, gold ball mill Baichy

Our Operation Citic Pacific Mining

Sep 18, 2021 First the ore goes into autogenous grinding mills and then ball mills, where the crushing process continues until it’s a fine powder At intervals in the crushing process, magnetic separation draws the valuable magnetite concentrate away from wasteThe RP4 shaker table is the most widely used and most successful gold gravity shaking concentrating table worldwide, used by small and large mining operations and hobbyists The patented RP4 is designed for the separation of heavy minerals and gemstone concentrate The RP4 table can process up to 100 lbs per hour of black sand magnetite or pulverized rock RP4 Gold Shaker Table Sale 911MetallurgistLowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities The results, highquality fine ore powders, are known as fines Magnetite Magnetite is magnetic, and hence easily separated from the Iron ore Wikipedia

Our Operations Fortescue Metals Group Ltd

The innovative process design, including the use of a dry crushing and grinding circuit, will deliver globally competitive capital intensity and operating costs The Iron Bridge project includes the installation of a 135km concentrate slurry pipeline to Port Hedland, together with a Feb 03, 2022 Surefire’s scoping study examined openpit magnetite ore mined at Perenjori being beneficiated using conventional crushing, twopass grinding and magnetic separation The company says metallurgical test work indicated Perenjori magnetite ore could be upgraded to a final concentrate product grading an eyecatching 675 per cent iron as a high Surefire unveils major WA iron potentialFeb 03, 2022 Surefire’s scoping study examined openpit magnetite ore mined at Perenjori being beneficiated using conventional crushing, twopass grinding and magnetic separation The company says metallurgical test work indicated Perenjori magnetite ore could be upgraded to a final concentrate product grading an eyecatching 675 per cent iron as a high Surefire unveils major WA iron potential The West Australian

First Quantum Minerals Ltd Our Operations

Metallurgical testwork indicates that the Taca Taca ore is amenable to grinding in a conventional SAG – ball milling circuit, with pebble crushing and regrinding, and flotation The Company has selected the scale and extents of open pit mining and ore processing, and the location and scope of required infrastructure itemsNotes: v03x and newer releases do not need CompatibilityLib installed v02x need CompatibilityLib installed, so that pottery can be carried around The Vintage Story mod "Bricklayers" adds useful things and new blocks to build Vintage Story Mod DBJun 06, 2019 In fact, some countries have more than 100 years worth of reserves of Bauxite The rock is easily obtained by open cast mining Blasting or drilling is used to uncover the bauxite layer under the topsoil, which are then broken and loaded onto trucks for crushing and washing before transport to alumina refineriesThe World's Leading Bauxite Producing Countries WorldAtlas

Mineral Processing an overview ScienceDirect Topics

Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsJan 11, 2022 “(Milestones included) the delivery and installation of the modules on site, installation of the first high pressure grinding roll in the tertiary crushing facility, completion of earthworks for Fortescue considers taking backseat at Iron Bridge Some recent grinding installations in Australia have demonstrated potential for ultrafine grinding with acceptable power consumption (Johnson, 1998) A combination of highpressure rolls and ultrafine grinding devices could potentially save energy in the production of ultrafine particles because they create microcracks during the crushing step3 Technologies in Exploration, Mining, and Processing

2 highyielding ASX 200 dividend shares to boost income

Jan 10, 2022 Fortescue said that the innovative process design, including the use of a dry crushing and grinding circuit, will deliver globally competitive capital Apr 04, 2018 We first discuss cement production and special nomenclature used by cement industrialists in expressing the composition of their cement products We reveal different types of cement products, their compositions, properties, and typical uses Wherever possible, we tend to give reasons as to why a particular cement type is more suitable for a given purpose than Cement Types, Composition, Uses and Advantages of Autogenous grinding The process of grinding ore in a rotating cylinder using large pieces of the ore instead of conventional steel balls or rods B Cone crusher A machine which crushes ore between a gyrating cone or crushing head and an inverted, truncated cone known as a bowl Magnetite Black, magnetic iron ore, Glossary of Mining Terms SEC

Agnico Eagle Mines Limited Operations Operations

Initial ore processing commenced in early February 2019 using lowgrade stockpiles The mill employs a conventional gold circuit comprising crushing, grinding, gravity separation and cyanide leaching with a carboninleach circuit, followed by cyanide destruction and filtration of the tailings for dry stackingAcademiaedu is a platform for academics to share research papersCoulson and Richardson's Chemical AcademiaeduOct 28, 2017 MANGANESE STEELS • Composition : • Carbon – 018 to 048% • Manganese – 16 to 19% • Silicon 02 to 035% • Manganese increases hardness and tensile strength • Increased resistance to abrasion and shock • Applications: Metallurgy SlideShare

Glossary of Mining Terms SEC

Autogenous grinding The process of grinding ore in a rotating cylinder using large pieces of the ore instead of conventional steel balls or rods B Cone crusher A machine which crushes ore between a gyrating cone or crushing head and an inverted, truncated cone known as a bowl Magnetite Black, magnetic iron ore, Initial ore processing commenced in early February 2019 using lowgrade stockpiles The mill employs a conventional gold circuit comprising crushing, grinding, gravity separation and cyanide leaching with a carboninleach circuit, followed by cyanide destruction and filtration of the tailings for dry stackingAgnico Eagle Mines Limited Operations Operations Academiaedu is a platform for academics to share research papersCoulson and Richardson's Chemical Academiaedu

Metallurgy SlideShare

Oct 28, 2017 MANGANESE STEELS • Composition : • Carbon – 018 to 048% • Manganese – 16 to 19% • Silicon 02 to 035% • Manganese increases hardness and tensile strength • Increased resistance to abrasion and shock • Applications: 2 days ago protected] The original modular conveyor is versatile and popular for recycling, composting, waste wood, sewage and more In order to correctly splice a belt several things need to be taken into consideration: Portable Dirt Conveyors These Portable Dirt Conveyors are designed for excavation and work with sand, gravel, cement, dirt, silt, rock, or any type of proximatecitJan 11, 2022 Fortescue said that the innovative process design, including the use of a dry crushing and grinding circuit, will deliver globally competitive capital 2 highyielding ASX 200 dividend shares to boost income

Development and Recent Progress on Ammonia Wiley

To produce this catalyst appropriate amounts of magnetite, iron, alumina, potassium nitrate, calcium carbonate, and other promoters were melted with 06 wt% Nb 2 O 5 at 1600 °C before crushing and sieving to obtain a catalyst with a granule size range of 10–20 mm Although the results suggest that the catalyst with Nb 2 O 5 has a slightly Nov 07, 2018 As tin consumption continues to grow in renewable energies, electric vehicles and innovative, a new market has been spawned for one of the world’s oldest metals giving it another time to shine and renewing interest in the metal for numerous ASX stocksTin stocks on the ASX: The Ultimate Guide Small CapsFeb 08, 2022 Altiplano Metals Inc is pleased to report on the ongoing construction activity at the El Peñón processing facility being built to support Altiplano Reports on Construction Progress at El Penon

Class 12 Chemistry Revision Notes for Chapter 6 General

Free PDF download of Class 12 Chemistry revision notes short keynotes for Chapter 6 General Principles and Processes of Isolation of Elements to score high marks in exams, prepared by expert Chemistry teachers from latest edition of CBSE(NCERT) books11 Period to advise chief executive about draft terms of reference—Act, s 45 For section 45 of the Act, the period is the later of the following periods to end— (a) 20 business days after the chief executive gives the proponent a copy of all comments received within the comment period; (b) if the chief executive and the proponent have, within the 20 business days, agreed to a longer View Queensland Legislation Queensland GovernmentFor information on South Africa's response to COVID19 please visit the COVID19 Corona Virus South African Resource PortalInstitute Of Infectious Disease and Molecular Medicine

IDM Members Meeting Dates 2022 Institute Of Infectious

IDM Members' meetings for 2022 will be held from 12h45 to 14h30A zoom link or venue to be sent out before the time Wednesday 16 February; Wednesday 11 May; Wednesday 10 August; Wednesday 09 Novemberdata:image/png;base64,iVBORw0KGgoAAAANSUhEUgAAAKAAAAB4CAYAAAB1ovlvAAAAAXNSR0IArs4c6QAAArNJREFUeF7t1zFqKlEAhtEbTe8CXJO1YBFtXEd2lE24G+1FBZmH6VIkxSv8QM5UFgM Education Development Center