Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

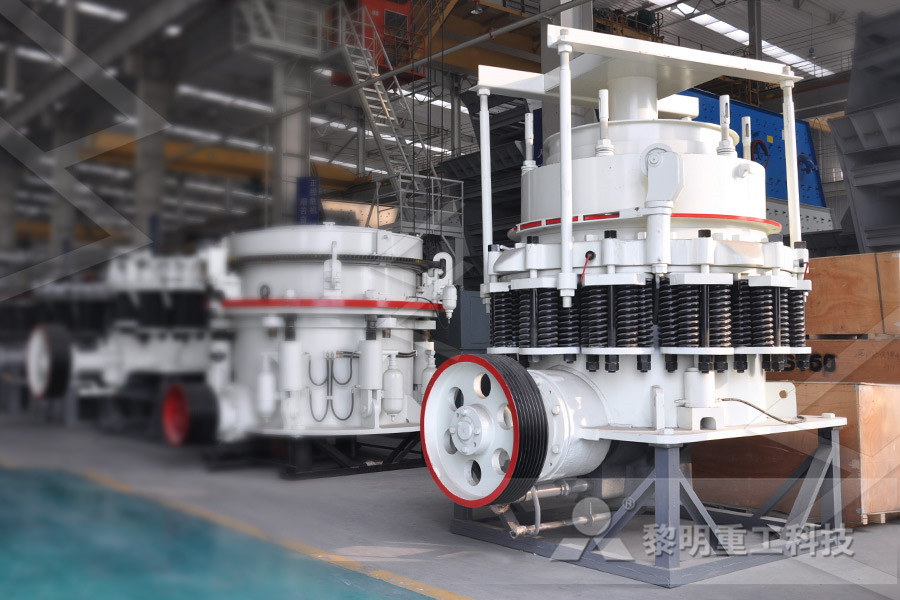

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mills an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball Nov 17, 2020 BALL MILL 1 KG Ball Mill 1 kg Motor Driven Heavy Duty with 10 Big Stainless Steel Balls (15 mm) and 35 Small Stainless Steel Balls (8 mm) Also Called Laboratory Ball Mill is used for preparation of samples for analysis with minimum loss of moisture of volatile constituents Weight distribution and balancing of rotating Continue reading BALL MILL 1 KGBALL MILL 1 KG Bexco ExportsBalls 4650 kg/m 3 Cylpebs 4700 kg/m 3 Rods 6247 kg/m 3 Cubes 5500 kg/m 3 For soft ore, ceramic media (90 °/o A l 2 0 3) can be used (2200 kg/m 3 ) Grinding media [images: mill media (13577)] Ball Mill Operation Ball mills ride on steel tires AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Energy Saving Ball Mill Ball Milling Machine Ball Mill

36 rows Cylindrical energy saving grid ball mill is one of energy saving mills developed Apart from the cement industry, it is also used in the paint, plastic, granite and tile industries The equipment is provided with a revolution counter for recording the revolutions Models available: Laboratory Ball Mill 5 Kg capacity (AIM 441) Laboratory Ball Mill 10 Kg capacity (AIM 44110) Laboratory Ball Mill 20 Kg capacity (AIM 441 20) BrandLaboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg Cylindrical Ball Mill is an efficient tool for grinding materials like ores, chemicals, ceramic raw materials, paints etc into fine powder or fine paste by grinding in a wet wayThe Ball Mill operates by rotating a cylinder with grinding balls like steel, CI, ceramic and pebble balls as grinding mediaBall Mills Cylindrical Ball Mill Manufacturer from Meerut

Ball Mills Mineral Processing Metallurgy

Feb 13, 2017 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentWet Ball Milling Hardened alloy spherical steel grinding media Load capacity of 454 kg 11,340 kg 1 mill at 454 kg capacity; 1 mill at 1,815 kg capacity; 7 mills at 2,268 kg capacity; 1 mill at 11,340 kg capacity; Ceramic Ball Mills with high alumina spherical grinding media 6 mills at 3,000 liter capacityToll Processing Services Ceramic Inorganic Powders 8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball Ball Mill an overview ScienceDirect Topics

The Effect of Ball Size Diameter on Milling Performance

An investigation was conducted to determine the effect of the ball diameter sizes on milling operation A laboratory size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively Quartz was the material used to perform the experiment and was arranged into 3 monosizes namely 8 mm +56 mm, 4 mm +28 mm and2Benefits One charge: 25 kg grinding media The grinding tank with stainless steel inner tank is designed for pressure less heating or cooling and holds 65 liters gross volume, 15 to 25 liters net volume Motor safety switch on the on/off button The W1S ball mill’s drive unit makes the ball mill for chocolate ideal for productionChocolate laboratory ball mill – MakingBall Mill For Grinding Lime Mortar Ball Mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes It works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shell It is of welded steel construction, having anBall Mills at Best Price in India IndiaMART

Ceramic Ball Mill Lining Bricks Grinding Media Duralox

Ball mills are the most commonly used mills to accomplish particle size reduction A revolving vessel, the ‘drum’, lined with ceramic bricks contains grinding media and the raw material to be ground 60% mill’s vol = 210 Ltr x 21 kg/Ltr (Bulk density of Duralox media) That is 441 kg of Duralox grinding media required for 350 Ltr A ball mill is a cylindrical machine and generally used for Grinding paints pigment, ores and other hard materials By rotating on horizontal axis the ball mill effectively turns hard materials into fine paste There are different ball mills on the market but all of them use the some working principle and are consisted of the same elementsBall Mill Manufacturer from Delhi Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding Large ore outlet and large capacity The mill with diameter below 21 meters adopts whole machine frame, which is convenient for civil construction and equipment installationEnergy Saving Ball Mill, Energy Saving Ball Mill

Ball milling as an important pretreatment technique in

Aug 12, 2021 For example, dry chemomechanical pretreatment of corn stover revealed that vibratory ball milling in the presence of NaOH appeared to be more effective to reduce lignin content and provide higher sugar yield (396 g/kg of dry biomass) compared to ball mill treated corn stover (207 g/kg of dry biomass) Jun 27, 2020 https://yatherm/shaker/ballmill/Laboratory ball mill operational video explains complete working The lab ball mill is installed in Cement factory for cLab Ball Mill 10 KG YouTubelattice type grinding wet ball mill ball grinder for lab Ball mill Wikipedia A ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding mediumGrinder Wet Ball Mill Cylindrical

equipement ball mill kg in macau Traxo

Jul 29, 2020 Ball Mill 1 Kg medical amp Lab Equipment Devices eBay Laboratory Ball Mill for mixing and grinding electrically operated capacity of a few grams to10 kg Fitted with FHP motor, The unit drives with maximum speed 80 RPM The jar is made of aluminium, having steel balls of different sizes to be fixed in a jar for mixing and grinding of Aug 01, 2019 BALL MILL 2 KG Used for preparation of samples for analysis with minimum loss of moisture of volatile constituents Weight distribution and balancing of rotating parts has been adjusted to provide greater stability and quiet performance with reduced vibrationBALL MILL 2 KG Variable Speed Bexco Exports8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter Figure 811 The feed can be dry with less than 3 moisture to minimize ball Chat Online; Small Ball Mills for Salesupplier machine cylindrical wet ball mill

Ball Mill 2 Kg Kfwscientificindustries

Ball Mill 2 Kg Brand – KFW Scientific Industries KFW Scientific Industries are a unique name in the industry to provide our precious clients an exclusive range of Ball Mill 2 kg Offered mill is precisely manufactured by our experienced 8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter Figure 811 The feed can be dry with less than 3 moisture to minimize ball Chat Online; Small Ball Mills for Salesupplier machine cylindrical wet ball millBenefits One charge: 25 kg grinding media The grinding tank with stainless steel inner tank is designed for pressure less heating or cooling and holds 65 liters gross volume, 15 to 25 liters net volume Motor safety switch on the on/off button The W1S ball mill’s drive unit makes the ball mill for chocolate ideal for productionChocolate laboratory ball mill – Making

Ball Mill an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball A ball mill is a cylindrical machine and generally used for Grinding paints pigment, ores and other hard materials By rotating on horizontal axis the ball mill effectively turns hard materials into fine paste There are different ball mills on the market but all of them use the some working principle and are consisted of the same elementsBall Mill Manufacturer from Delhi Ball Mill Grinding In Knn Processing ball mill grinding in knn processing ist of ball mill rock phosphate grinding suppliers cement mill grinding ball ball mill for fly ash grinding coal ball mill for Ball mill Wikipedia A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsball mill grinding in knn processing dentalleu

Lab Ball Mill 10 KG YouTube

Jun 27, 2020 https://yatherm/shaker/ballmill/Laboratory ball mill operational video explains complete working The lab ball mill is installed in Cement factory for c3 Lb Capacity Ball Mills N4mdv purelinebe Ball Mill 15 Lb 15 lb capacity high speed ball mill Larger size for the more serious hobbyist to mill black powder rocket propellant and other in larger quantities 18 cups far more efficient than the 3 lb unit due to the flat 6 sided interior surface of the barrel and even more efficient then the old style 15 mills10 Lb Ball MillsMTI has been manufacturing laboratory mill/mixer since 1994 We've been devoting ourselves to designing the most efficient, practical, and affordable laboratory mill/mixer Thus, many new and fashion models are gradually stepping and finding a place in the specification market where to cumulate most of the elites involved in the new generation laboratory mill, lab ball mill

Vibratory Ball Mills Powder Metallurgy Beyond Discovery

Jan 07, 2022 The vibratory ball mill is an excellent means of producing solidstate alloyed and dispersionstrengthened metals in amounts up to 45 kg (10 lb) or more, depending on the apparent density of the powder Figure 21 (a) and 21 (b) show the microstructure of an aluminumironcerium alloy and a transmission electron micrograph of oxide dispersion China Ball Mill Machine manufacturers Select 2022 high quality Ball Mill Machine products in best price from certified Chinese Mill Equipment, Grinding Mill suppliers, wholesalers and factory on MadeinChinaChina Ball Mill Machine, Ball Mill Machine Manufacturers Application of ball grinding mill The ball grinding mill is a key piece of equipment utilized for grinding crushed materials A ball grinding mill consists of a hollow cylindrical shell which is partially filled with balls The grinding media is the steel balls which can be used for reducing the size of materials to a fine powderBall Mill Ball Mill Manufacturer SINOMALY

Cylindrical mill All industrial manufacturers

Find your cylindrical mill easily amongst the 10 products from the leading brands (Hosokawa, WAMGROUP, ) on DirectIndustry, the industry specialist for your professional purchasesIntroduction to ball mill It is widely used in cement and silicate products; new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics and other mineral production industries of all kinds of ores and other grindable materials can be dry or wet grindingBall mill,Cylindrical ball mill,Ball mills