Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

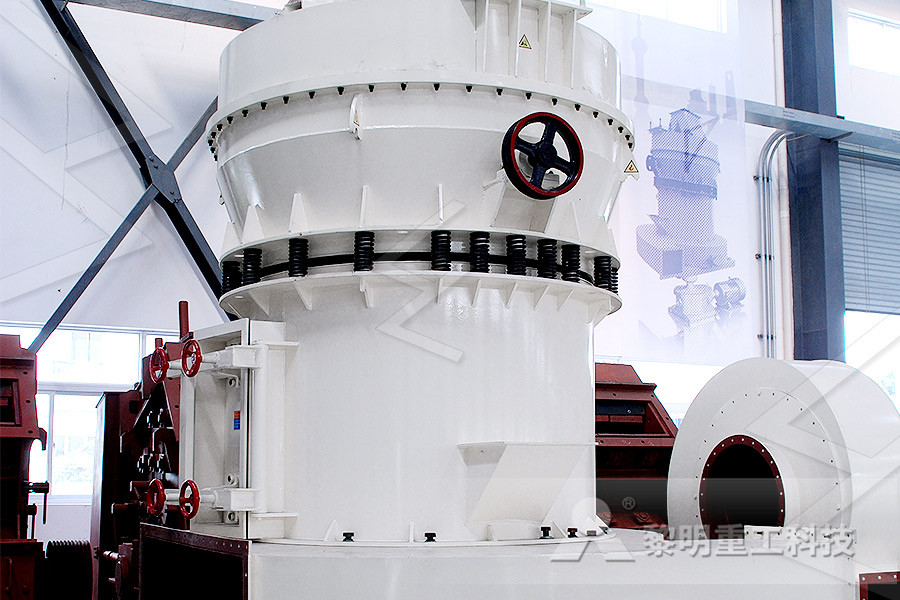

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cement Manufacturing Process Civil Engineering

Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inchesPortland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspecialty groutIt was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and is usually made from limestoneIt is a fine powder, produced by heating limestone and clay minerals in a kiln to form Portland cement WikipediaAug 17, 1971 Portland cement accounts for 95 percent of the hydraulic cement production in the United States The balance of domestic cement production is primarily masonry cement Both of these materials are produced in portland cement manufacturing plants A diagram of the process, which encompasses production of both portland and masonry cement, is shown 116 Portland Cement Manufacturing

Manufacturing of Cement By Dry and Wet Process

In the manufacturing of cement, the following three important and distinct operations occur: Mixing of Raw materials Burning; Grinding; The process, by which cement is manufactured, depends upon the technique adopted in the mixing of raw materials Therefore, on the basis of mixing the raw materials, the processes may be classified as:Jan 24, 2022 Which are the biggest cement companies in USA? Check below 10 Leading Cement Manufacturing Companies in United States American cement companies produce more than four percent of the world’s cement, making USA the third largest cement producer after China and India Most of the largest cement companies in USA are multinationals having Top 10 Largest Cement Manufacturing Just CredibleAug 30, 2012 The remaining cement is shipped in bulk quantities by mean of trucks, rails or ships Cement Manufacturing Process Flow Chart After explaining the complete process of cement making, flow chart would be like that flow chart present the summary of whole process as shown belowCement Manufacturing Process Phases Flow Chart

Robust layer interface in cement additive manufacturing

Jan 04, 2022 1 Introduction Additive manufacturing has been introduced to cementitious materials in recent years to develop 3D concrete printing (3DCP) for its advantages on the high automation degree and outstanding design flexibility , However, this fabrication mode through depositing materials layer by layer inevitably brings interface, including horizontal interface all wastages In cement manufacturing process raising etc quality of product, the cost should be minimize, improving delivery of product, reducing wastages Implementation of cement industry day by day to increase the productivity beneficial for our future New technique be developed to proper control cement manufacturing processRisk Assessment in Cement Manufacturing ProcessCertain cement manufacturing plants only produce certain types of portland cement What are the differences in these cement types and how are they tested, produced, and identified in practice? These are designated by letters in parentheses following the cement type For example Type IP(MS) is a portlandpozzolan cement with moderate sulfate Cement Types Portland Cement Association

Sustainability Portland Cement Association

America’s cement producers have a strong culture of innovation that has led to gains in energy efficiency and new sustainable manufacturing practices that continually reduce environmental impacts Over the last 40 years, US cement manufacturers have reduced the energy used to produce a metric ton of cement by roughly 40 percentCement kilns are used for the pyroprocessing stage of manufacture of portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silicatesOver a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plantCement kiln WikipediaClear Regular Body PVC Cement: PVC 02TS Technical Specifications : Clear Regular Body PVC Cement: PVC 05TS Technical Specifications : Clear/Gray Medium Body PVC Cement: PVC21TS Technical Specifications: Blue Medium Body Cement: PVC25TS Technical Specifications : Aqua Blue WetNDry Dry Cement: PVC26TS Technical SpecificationsProduct Specifications Spears Manufacturing, PVC

Cement Manufacturing Process Flow Chart

1 Convert the following flow chart into a paragraph of about 150 words The process of making cement is described in this flow chart The two raw materials used in theprocess are limestone and clay Limestone is crushed, sized, dried and stored in storage silos In the same way, Clay is washed, crushed, and dried in storage basinsPortland cement manufacturing is a threestep process: Cementmaking requires calcium, silica and small amounts of alumina and iron Raw materials rich in these elements include limestone, sand and clay They are quarried at the cement manufacturing plant or shipped from nearbyPortland Cement Lehigh Hanson, IncFollowing is a sampling of some of the asbestoscontaining products manufactured or distributed by companies for use in the American marketplace This list is not allinclusive A P Green Industries, Inc A P Green Insulating Cement (19471971) Castable Block Mix (19551972) Castable Mix 204 (Victor Manufacturing and Gasket Company) A Listing of Asbestos Products by Manufacturing Company

The Cement Industry, One of the World’s Largest CO2

Dec 28, 2018 The Londonbased organization, founded in January 2018 to “drive advances in sustainable construction while demonstrating industrial sustainable leadership in cement and concrete manufacturing,” announced the industry’s first “Sustainability Guidelines” following the conclusion of the COP24 climate conference in Poland this DecemberThe company has its own cement manufacturing units in the following states: Chhattisgarh, Bihar, Uttar Pradesh, Uttarakhand, Haryana, and Rajasthan The price of cement is very affordable, which attracts the user and, in terms of quality, it is also good, in addition, it can be discussed with the builder of your homeTop 10 Best Cement Companies In India 2022 CivilJungleNov 02, 2021 Caribbean Cement Company Limited is a member of the TCL Group The TCL Group comprises companies located in Trinidad, Barbados, Jamaica and and Guyana The major activity of the Group is the manufacture and sale of cement and concreteHome Caribbean Cement Company Limited

NT ADVANTAGE Nyati Cement

Our integrated cement manufacturing unit, spread over an area of 100 hectares, is the most modern, fully automated and energy we have introduced following technologies at our Plant A stateoftheart dry process technology for producing cement It is monitored by aBorn to the 129 yearold multidisciplinary industrial conglomerate JK Organisation, JK Cement is one of the leading manufacturers of Cement in the Country The Company has over four decades of experience in the cement manufacturing industry, having Grey Cement plants in Nimbahera, Mangrol and Gotan, Rajasthan, Muddapur in Karnataka and Jhajjar Jobs at JK CementPreparation of cement This stage completes the manufacturing process where clinker nodules are milled into cement Following clinker milling, the cement is ready for use as a binder in various concrete mixesCement Production an overview ScienceDirect Topics

CONCRETE MIXER MACHINES Mix cement efficiently with

See live videos of these cement mixture machines taken at construction sites across India to understand how cement, water and aggregates are mixed in a concrete mixer machine India Sales: +91 International Sales: +91 It is a special cement that has been customized for manufacturing hollow blocks, solid blocks, paving blocks, fly ash bricks and other precast items To ensure the productivity and quality of precast blocks, a separate line meant for manufacturing the specialized cement has been installed at our plantsBest Cement in India Cements Indian Cement Ramco The cement manufacturing process is complex and energy input is required at every stage, and various processes involved lead to emissions of C02 and other greenhouse gases Cement accounts for 83% of total energy use in the production CEMENT INDUSTRY The Energy and Resources Institute

Cement Production an overview ScienceDirect Topics

Preparation of cement This stage completes the manufacturing process where clinker nodules are milled into cement Following clinker milling, the cement is ready for use as a binder in various concrete mixesIndustrial projects require mass concreting type of mixers SAFARI manufactures reversible drum concrete mixers to meet this requirement SAFARI 3000 also known as RM 800 produces concrete at the approximate rate of 12 cubic meter per hour, while SAFARI 5000 also known as RM 1050 has output of 15 cubic meter per hourCONCRETE MIXER MACHINES Mix cement efficiently with It is a special cement that has been customized for manufacturing hollow blocks, solid blocks, paving blocks, fly ash bricks and other precast items To ensure the productivity and quality of precast blocks, a separate line meant for manufacturing the specialized cement has been installed at our plantsBest Cement in India Cements Indian Cement Ramco

CEMENT INDUSTRY The Energy and Resources Institute

The cement manufacturing process is complex and energy input is required at every stage, and various processes involved lead to emissions of C02 and other greenhouse gases Cement accounts for 83% of total energy use in the production Dec 07, 2015 A concern for the environment is an integral part of the company's vision UltraTech Cement Limited is committed to growth in consonance with the ecology and the needs of the communities it serves Ultratech Cement Limited is India`s Largest Cement Producer, with a manufacturing capacity of over 17 million tons per yearPROJECT ON ULTRATECH CEMENT SlideShareOct 10, 2021 Costs may be classified as manufacturing costs and nonmanufacturing costs This classification is usually used by manufacturing companies Manufacturing costs: Manufacturing costs can be further divided into the following categories: Direct materials Direct labor Manufacturing overhead The above three categories of manufacturing costs are Manufacturing and nonmanufacturing costs explanation

GFRC Stromberg Architectural Glass Fiber Reinforced

GFRC is a composite of cement, glass fibers, aggregates and polymers Stromberg GFRC pioneered the design and production of glass fiber reinforced concrete and our unique methods of detailing, manufacturing and installing GFRC that have helped make our clients, and their projects, successfulApr 05, 2020 Detailed below are the raw materials and the properties they impart to the cement powder Raw Materials for Ordinary Portland Cement Manufacturing The crude materials required for manufacturing cement are either calcareous or argillaceous Calcareous materials contain high content of lime whereas argillaceous ones comprise high percentages of Chemical Composition Of Cement Construction How11 Which one of the following industries uses limestone as a raw material? (a) Aluminium (b) Cement (c) Chemical (d) Fertiliser 12 Which one of the following agencies, markets steel for the public sector plants? (a) HAIL (b) SAIL (c) TATA Steel (d) MNCC 13 Which one of the following industries uses bauxite as a raw material ? (a) Aluminium Manufacturing Industries CBSE Class 10 SST Geography

50 Small Business Manufacturing Ideas Small Business Trends

Feb 02, 2017 Cement Maker Or you could mix cement material or make cement blocks to sell to construction companies Tool Manufacturer You can also focus your efforts on manufacturing a wide variety of small tools and accessories Nail and Bolt Manufacturer For those looking to specialize in a smaller product, you can make small nails and bolts in bulkJan 28, 2022 Aggregate Industries, the Swiss owners of one of Northern Ireland’s biggest cement operations, has sold the business to Cookstown Cement for an undisclosed sum The sale includes all the businesses of Lafarge Cement Ireland, including a cement plant with production capacity in excess of 450,000 Cookstown Cement buys Lafarge Ireland business and Jul 03, 2019 The Portland cement is used to make mortar Ordinary Portland cement is most suitable for common construction purposes For making composite mortars, Lime is also used Also Read: Manufacturing Process of Ordinary Portland Cement (OPC) Sand must be of good quality and it should be free of impurities like clay, dust, oxide of irons etcCement Mortar: Its Proportion, Preparation, and Uses!

New Year may begin on a gloomy note for cement companies

Dec 29, 2021 Cement prices have declined mom across regions, a factor likely to weigh on Q3 margins Following that, investors would closely watch whether cement demand revives meaningfully in the March Humboldt manufactures construction materials testing equipment for use with soil, concrete, cement and asphalt materials Humboldt has geotechnical and soil mechanics equipment like triaxial, consolidation and direct shear involving ASTM standardsConstruction Materials Testing Equipment Humboldt Mfg