Solutions

Products

-

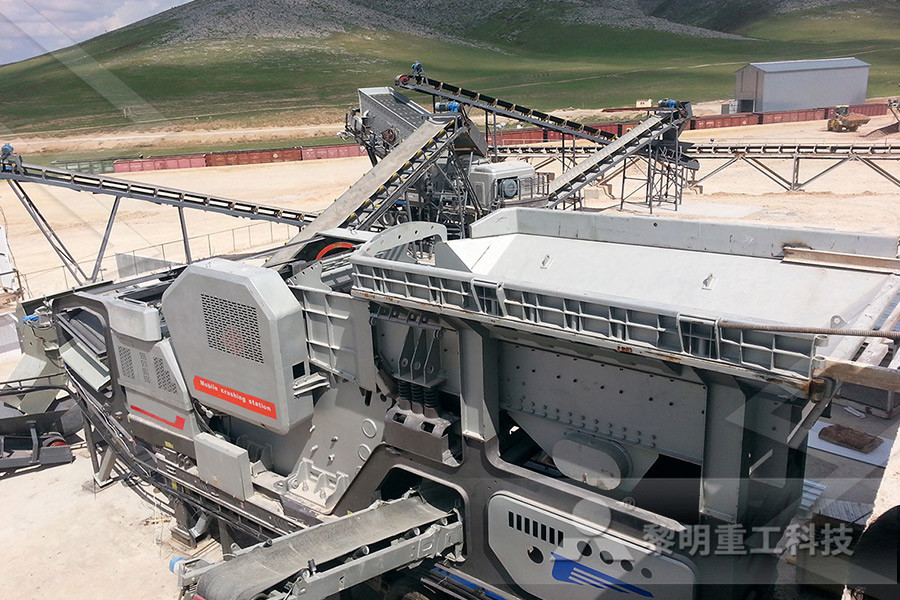

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

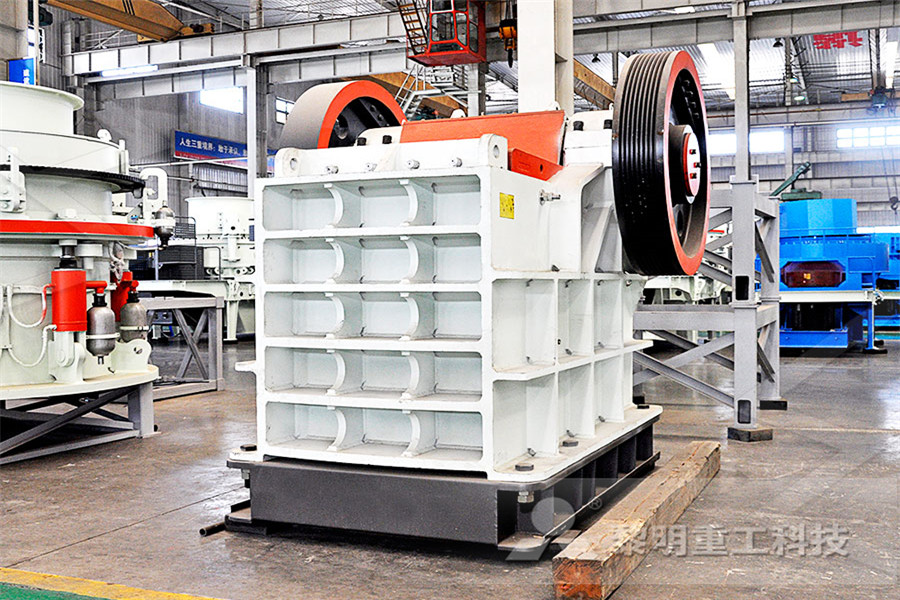

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Chilled Water Schematics The Engineering Mindset

Apr 18, 2018 Firstly, every chilled water schematic you look at will be completely different The symbols used are always similar, enough to recognise Taco InLine Air Separators are applied in commercial, institutional and industrial applications for the removal of free air in water or water/ glycol systems The InLine designed air separator utilizes the advantages resulting from large body diameter in relation to the entering nozzle diameter The design of inline air separators depends uponInLine Air Separators TACO HVACRolairtrol Air Separator Hot Chilled Water The Bell Gossett Rolairtrol® is a patented centrifugal style air separator for use in any HVAC system Its 3to1 body diameter to nozzle diameter ratio slows the fluid velocity to help entrained air come out of solution, while its tangential inlet and outlet nozzles induces centrifugal fluid flowRolairtrol Air Separator Hot Chilled Water Xylem

Chilled Water System: Components, Diagrams Applications

A chiller is made up of the 4 major components required for the refrigeration process which are: a) compressor, b) condenser, c) evaporator and d) expansion valve To produce chilled water, the refrigerant absorbs heat from the water and thus, chilling the water to about 67°C (44°F)Rolairtrol® Air Separator For Hot and Chilled Water Systems A305G REMOVES ENTRAINED AIR • To protect the system against damage • To eliminate system noise TANGENTIAL FLOW PATTERN • Increases air separation efficiency • Allows use of smaller sizes than required with straight flow separators MODELS UP TO 36” PIPE SIZERolairtrol Air Separator Xylem Applied WaterOct 17, 2012 Chilled Water Systems Back to Basics Jonathan Ramajoo Peter Wise •Often a simple schematic of a system is easier to understand than oneliners in a specification “A picture tells a thousand words” Air and Dirt Separators required, what size, what type etc • Often, too many are specified and canChilled Water Systems Back to Basics Jonathan Ramajoo

Air Separator Brochure Amtrol Water System Solutions

For Closed Hydronic Heating Chilled Water Systems Amtrol tangential air separators are designed to create a low velocity vortex that separates and removes entrained air from circulating water or antifreeze in a closed, nonpotable water system Available in 1" to 24" sizes with an optional stainless steel strainer toRolairtrol® Air Separator For Hot and Chilled Water Systems A305G REMOVES ENTRAINED AIR • To protect the system against damage • To eliminate system noise TANGENTIAL FLOW PATTERN • Increases air separation efficiency • Allows use of smaller sizes than required with straight flow separators MODELS UP TO 36” PIPE SIZERolairtrol Air Separator Xylem Applied WaterFor Closed Hydronic Heating Chilled Water Systems Amtrol tangential air separators are designed to create a low velocity vortex that separates and removes entrained air from circulating water or antifreeze in a closed, nonpotable water system Available in 1" to 24" sizes with an optional stainless steel strainer toAir Separator Brochure Amtrol Water System Solutions

Chilled Water System: Components, Diagrams Applications

A chiller is made up of the 4 major components required for the refrigeration process which are: a) compressor, b) condenser, c) evaporator and d) expansion valve To produce chilled water, the refrigerant absorbs heat from the water and thus, chilling the water to about 67°C (44°F)Oct 17, 2012 Chilled Water Systems Back to Basics Jonathan Ramajoo Peter Wise •Often a simple schematic of a system is easier to understand than oneliners in a specification “A picture tells a thousand words” Air and Dirt Separators required, what size, what type etc • Often, too many are specified and canChilled Water Systems Back to Basics Jonathan Ramajoo Fig2 Schematic drawing of pressurisation unitV expansion tank and air separatorI v Water Tank Expansion Tank Pressurisation Unit Air Separator FromAHU’S ToAHU’S Drain Valve Isolation Valve To Drain Drain Valve v NRV Pump Chillers Primary Pumps Secondary Pumps NRV v Pump)ORAC ( Ph F H F H F H Control Panel Transmitter BMS Remote Nf Pressure PRESSURISATION UNITS Anergy

Air Cooled Chillers etcgrp

The lower the pressure, the colder the chilled water temperature Raising the chilled water supply temperature • raises the evaporator pressure • decreases compressor work • improves system efficiency by around 15% per degree F • Example: raising chilled water supply temperature by 10 degrees would reduce compressor energy by roughly 15%1Low return water temperatures 2Robs chilled water from other coils at part load conditions 3Increases flow in primary piping 4Adds additional chillers on line 5Chiller performance is reduced 3way Valve System DeficienciesChilled Water System Presentation HVAC Việt NamJMP Equipment Company 603 Diamond Hill Ct Greensboro, NC 27406 Phone: (800) 3659010 After Hours Parts: (888) 2137278Chilled Water HVAC

Hydronic HVAC Systems: MakeUp Water Assembly, Initial

MakeUp Water (MUW) Assembly: The link between the hydronic system and the domestic water feed The MUW assembly includes a Pressure Reducing Valve (PRV), a Pressure Relief Valve, and full size bypass piping for use during initial system fill Usually connects to the hydronic system at the air separator inlet (lowest pressure point and remove chiller capacity watercooled aircooled 1,500 tons1,500 tons [5,276 kW] 2,500 tons [8,793 kW] 500 tons [1,759 kW] 3,000 tons [10,551 kW] Figure 9 TRGTRC016EN 7 period one Types of Water Chillers notes A major advantage of using an aircooled chiller is ChilledWater Systems One of the Systems Series / Air outdoor air thermostat setatdf [et1]diahragm expansion tank see detail / automatic air vent from heating system air separator gate valve, typ flexible type mechanical couplings typ suction diffuser todrain '\ combination boiler feed and low water cutoff 3waycontrol valve vlvb101 lowwater cutoff cw makeup,pressure relief valve, discharge Mechanical CAD Details

Chilled Water Buffer Tanks (CWB) Cemline

The CWB reduces the rate of change of the return water Chillers are designed to be useful in systems with a minimum water volume The minimum water volume is based upon the chiller manufacturer's requirements, 3 to 6 gallons per ton for typical air conditioning and when the temperature accuracy is critical 6 to 10 gallons per ton Inline Air Separators These separators operate by collecting air off the top of the water flow The air is then directed back to the compression tank and vented to the atmosphere The sizing of this type of air separator is based on the velocity of the water which is determined by the flow rate Centrifugal Force Air SeparatorsWarming Up to Chillers A Guide to Understanding Chilled Feb 07, 2022 Grooveend connections are furnished as required 6" and below are schedule 40 pipe, 8" and above are schedule 30 pipe An example of piping a buffer tank follows showing a water source heat pump application In all applications note that the tank top fitting should be piped the distribution supply line to the air purger and vent41 buffer tank piping diagram Wiring Diagrams Manual

ChilledWater Systems One of the Systems Series / Air

chiller capacity watercooled aircooled 1,500 tons1,500 tons [5,276 kW] 2,500 tons [8,793 kW] 500 tons [1,759 kW] 3,000 tons [10,551 kW] Figure 9 TRGTRC016EN 7 period one Types of Water Chillers notes A major advantage of using an aircooled chiller is air dirt separators for closed hydronic heating and chilled water systems installation operation instructions models 2ads through 12ads including magnetic separator option read carefully the product installation operation instructions failure to follow the instructions and warnings in the manual may result in serious or fatal injury and/AIR DIRT SEPARATORS Amtrol Water System SolutionsThe lower the pressure, the colder the chilled water temperature Raising the chilled water supply temperature • raises the evaporator pressure • decreases compressor work • improves system efficiency by around 15% per degree F • Example: raising chilled water supply temperature by 10 degrees would reduce compressor energy by roughly 15%Air Cooled Chillers etcgrp

Air Separators Amtrol Amtrol Water System Solutions

Amtrol ASME tangential air separators are designed to create a low velocity vortex that separates and removes entrained air from fluids circulating in closed, heating and chilled water systems Available in 1” to 24” sizes with optional stainless steel strainer to collect unwanted system debris FEATURES SPECIFICATIONS Inline Air Separators These separators operate by collecting air off the top of the water flow The air is then directed back to the compression tank and vented to the atmosphere The sizing of this type of air separator is based on the velocity of the water which is determined by the flow rate Centrifugal Force Air SeparatorsWarming Up to Chillers A Guide to Understanding Chilled Single Line Diagram Using the diagrams provided by eQuest and our own knowledge of HVAC systems, the following riser diagrams were drawn Chilled Water Riser Diagram Hot Water Riser Diagram In the schematic of our design, we have a chiller on the rooftop, air handling unit, boiler and other equipment in the basementSingle Line Diagram Spacecraft Museum

Air versus watercooled chilled water plants Consulting

Apr 10, 2020 A watercooled chilled water plant consists of a watercooled chiller, typically located inside the building They also can be placed outside the building and include chilled water pumps, an expansion tank, an air separator, chemical treatment, cooling towers located outside of the building, condenser water pumps, makeup water to accommodate evaporation circuit supply water temperature will be lower than a boiler and higher then the chiller primary circuit supply water temperature This is because some of the secondary flow mixes with the primary flow and dilutes the supply water temperature to the secondary circuit This can cause system performance problems, especially in chilled waterHydraulic Separator TACOOct 19, 2017 • The watercooled condenser is typically part of a watercooled chiller or watercooled package unit • A cooling tower rejects the condenser heat to the atmosphere • Flow rates and temperatures are industry standards for North America • Piping and pumps circulate water • Water is reused and exposed to the ambient conditionsWater Piping and Pumps Sigler Commercial

Chilled Water Buffer Tanks (CWB) Cemline

The CWB reduces the rate of change of the return water Chillers are designed to be useful in systems with a minimum water volume The minimum water volume is based upon the chiller manufacturer's requirements, 3 to 6 gallons per ton for typical air conditioning and when the temperature accuracy is critical 6 to 10 gallons per tonChilled water flows thru the evaporator The evaporator is a heat exchanger 2 Chiller compressor may be centrifugal, scroll, screw or reciprocating 3 The condenser may air cooled or water cooled 4 There can be multiple chillers in a chw plant 4 FLOW CALCULATION 1 Common design condition is supply water 44 F ,return water 54 F temperature Chilled water piping basics SlideShareThe outside air damper shall open 100%, the return air damper shall close fully and the exhaust fan shall run on high speed On sensing that the ambient air is not appropriate to meet the cooling requirements, the chilled water control valve shall modulate as required to meet the space cooling set point: During cooling season unit will be offSequence of Operation AirCooled Chiller

Secondary Chilled Water Loop – Plate Heat Exchanger: Plant

Secondary Chilled Water Loop – Plate Heat Exchanger The Secondary Cooling system is constructed by using a PlantLoop object, the working fluid in this loop is water It uses one side of a plate heat exchanger (modeled using a HeatExchanger:FluidToFluid object) to supply chilled water to a cooling coil (modeled by using a Coil:Cooling:DetailedGeometry object)System Efficiency Buffer Tank (SEB Series) CEMLINE® Primary/Secondary Buffer Tank, Air Separator Cemline primary/secondary buffer tanks improve system efficiency by preventing the problem of short cycling boiler (s) Low water content boilers operating at low loads will short cycle leading to sooting, premature component failure, and nuisance System Efficiency Buffer Tank (SEB)