Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

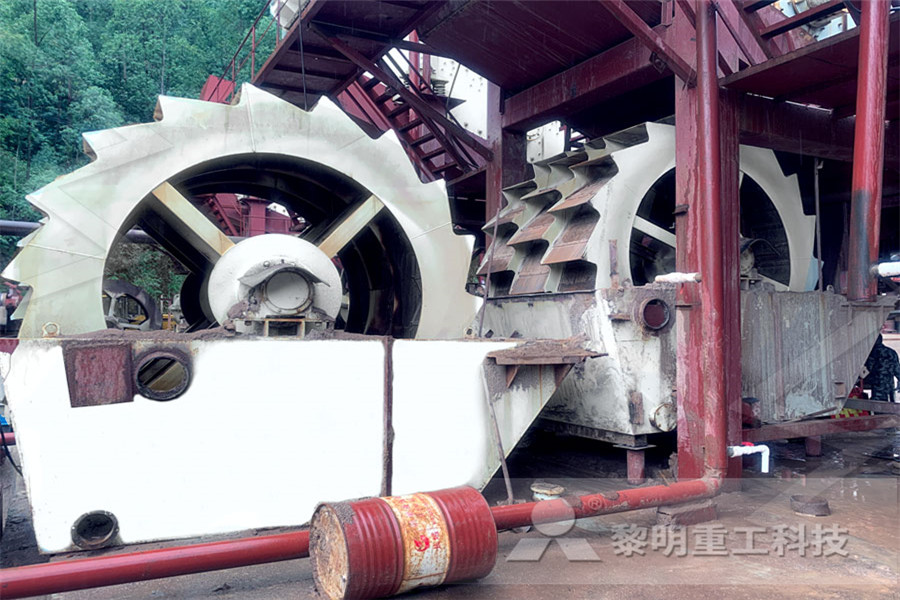

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

CAA1 Horizontal shaft impact crusher feed

this object is achieved by means of a method of feeding material to be crushed to a horizontal shaft impact crusher, the method comprising feeding, when the crusher operates in Aug 12, 2014 Screen Machine Industries is a leading manufacturer of portable jaw, impact and cone crushers, screening plants, trommels and conveyors and a global leader i4043T Impact Crusher Feeding 622TH Triple Deck Nov 04, 2021 In order to prevent the impact plate by vibration, nut loose and gradually decline and plate hammer collision, resulting in accidents Since the discharge port of the impact crusher is at the bottom, the installation height and how to cooperate with the feeding and discharging devices should consider in the system designInstallation and Maintenance of Impact Crusher large

4K CAT 330 Feeding A Impact Crusher CAT

Aug 24, 2020 A 330 Excavator digs and loading a MOBIREX MR130Z EVO2 Impact crusher with demolition debris with rebars, while the CAT 962M Wheel loadeMay 13, 2019 This is why it is vitally important that the feed arrangement to an impact crusher ensures an even distribution of feed material across the full width of the rotor This will allow for even distribution of energy into the feed material and uniform wear patterns, ensuring consistent product gradation and power consumption Setting impact crushersTips to maximize crushing efficiency Pit Quarry : Pit The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect Topics

Impact Crusher

The JOYAL Impact Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone The Impact Crusher is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so onA horizontal shaft impact crusher feed chute (8) adapted for receiving material to be crushed and for forwarding the material to a crushing chamber (10) of a horizontal shaft impact crusher (1) comprises a first opening (56) adapted for receiving material to be crushed in a first crushing setting, and a second opening (58) adapted for receiving material to be crushed in a second CAA1 Horizontal shaft impact crusher feed chute Advantages of Impact Crusher 1 Big feeding opening, high crushing cavity It is used for crushing high hardness and large lump material, and only producing less stone powder 2 The design of adjustable clearance between impact plate and board hammer can effectively control the discharging size and particle shape of products 3Impact Crusher

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Jun 22, 2015 Impact Crusher Buy a small impact crusher: (>50%) of the total energy input to the crusher and markedly different power rates (energy input per unit of crusher feed) can be obtained by varying ore feedrates and/or crusher parameters such as closed side setting It will Impact Crusher Working PrincipleThe 4800 Series Impact Crushing Plants from are the ultimate, completely selfcontained, easy to transport crushing plants that offer the features contractors need, like a larger crusher feed opening that devours concrete full of rebar, ripped asphalt and other CD debris The heart of the plant is a 4248LP Impact Crusher, aIMPACT CRUSHERS Power Equip

4043T IMPACT CRUSHER

4043T Impact Crusher Specifications CRUSHER • 40" diameter rotor x 43" wide (1,016mm x 1,092mm) impact crusher • Lid Crusher Relief System™ with 6" (152mm) raise feature • Feed inlet opening: 43" wide x 28" high (1,092mm x 711mm) • 2 adjustable curtains (apron wrench tool provided) • Maximum primary curtain adjustment of 8" (203mm)Moreover, the aggregates jaw crusher for primary crushing is 300350mm, while those of impact limestone crushers are smaller The shape of final products impact crusher quarry makes are better than those of jaw crusher Third, supposing their models are similar, the output of jaw crusher is higher than mobile impact crusher for saleImpact Crushers Of Various Types Model With Low PriceNP impact crusher is quite simple There are however many things that all have an impact on machines output Feeding, speed, feed material, water content, wear part selection and settings are just examples of all the possible factors affecting through put optimation Following table gives you some hints how to adjust NP impact NP series impact crushers Wear parts application

PLS Vertical Shaft Impact Crusher/VSI Crusher/Sand Making

PLS Vertical Shaft Impact Crusher/VSI Crusher/Sand Making MachineMax Feed Size: 3060 mmProcessing Capacity: 16715 TPHOutput Size: 05 mmApplied Materials:The mobile impact crusher MOBIREX MR 130 EVO2 can be deployed universally as an allrounder and produces first class final product quality With a crusher inlet width of 1300 mm, it achieves a production rate that until now was only associated with considerably larger crushing plant This is made possible by outstanding cost effectiveness and MR 130 EVO2 Mobile impact crushers Model: Fullstar90, Production capacity: 120180 Tons Per Hour, 2nd crusher: Secondary Impact Crusher, Maximum feeding size: 600 mm, :crushersscreeningplants in Niger

Common Faults of Impact crusher Crusher Blog

Aug 03, 2011 Filed Under crusher failure, impact crusher First, impact crusher vibration 1 the material is too large, you can check the feed size 2uneven wear, indicating the need to replace the hammer back, 3 rotor imbalance, the need to adjust 4based handled properly, need to check the anchor bolts and reinforcementThe mobile impact crusher MOBIREX MR 110 EVO2 can be deployed universally and produces first class final product quality With a crusher inlet of 1100 mm and numerous technical highlights, a formidable production rate can be achieved with best cost effectiveness Thanks to its compact design, the machine is easy to transport and can be MR 110 EVO2 Mobile impact crushers The impact crusher is a highly efficient coarse, medium and fine crusher for mediumhard and softer rocks Whether in a quarry, mining or Construction waste recycling, the impact crusher can efficiently crush the stone, so that the particle shape, particle size distribution and cleanliness are in line with the strict standards of concrete and asphalt aggregateWhat Is Impact CrusherWorking Principle, Parts And Types

METHOD OF FEEDING MATERIAL TO A HORIZONTAL SHAFT IMPACT

May 24, 2013 A crushing device includes a horizontal shaft impact crusher having an impeller rotating around a horizontal shaft and at least one curtain against which material may be crushed The crushing device further includes a first feeding device for feeding a first type of material to be crushed to a crushing chamber of the horizontal shaft impact crusherJun 22, 2015 Impact Crusher Buy a small impact crusher: (>50%) of the total energy input to the crusher and markedly different power rates (energy input per unit of crusher feed) can be obtained by varying ore feedrates and/or crusher parameters such as closed side setting It will Impact Crusher Working PrincipleThe Features of Mobile Impact Crusher The Working Principle of Mobile Impact Crusher The vibrating feeder puts the material into the impact crusher at a uniform speed, and crushes it by means of impact energy, which drives the Mobile Impact Crusher,the Best Choice For Broken

IMPACT CRUSHERS Power Equip

The 4800 Series Impact Crushing Plants from are the ultimate, completely selfcontained, easy to transport crushing plants that offer the features contractors need, like a larger crusher feed opening that devours concrete full of rebar, ripped asphalt and other CD debris The heart of the plant is a 4248LP Impact Crusher, aMay 20, 2013 A vertical shaft impact crusher feed tube arranged for protecting a rotor feeding opening of a feeding funnel of a vertical shaft impact crusher The feed tube includes a tube portion via which material may flow from the feeding funnel and vertically downwards into a rotor The tube portion has a first width at a material inlet, and a second width at a material US Patent for Vertical shaft impact crusher feed tube The impact crusher is a highly efficient coarse, medium and fine crusher for mediumhard and softer rocks Whether in a quarry, mining or Construction waste recycling, the impact crusher can efficiently crush the stone, so that the What Is Impact CrusherWorking Principle, Parts

4043T IMPACT CRUSHER

4043T Impact Crusher Specifications CRUSHER • 40" diameter rotor x 43" wide (1,016mm x 1,092mm) impact crusher • Lid Crusher Relief System™ with 6" (152mm) raise feature • Feed inlet opening: 43" wide x 28" high (1,092mm x 711mm) • 2 adjustable curtains (apron wrench tool provided) • Maximum primary curtain adjustment of 8" (203mm)Impact Crusher small, medium and large models are in stock available Feeding Size: 50800mm Processing Capacity: 15800t/h Hot model PF1007 PF1010 PF1315 PF1320 Output size different sizes for 120 kinds of stones Impact Crusher Zhengzhou Shibo Mechanical Deepa Horizontal Impact Crushers of robust welded construction, stress relieved and can be assembled and serviced easily The impactors internal hull is fully layered with wear resistant lining plates The body is of three parts bottom Deepa HSI (Horizontal Shaft Impact) Crusher Deepa

PLS Vertical Shaft Impact Crusher/VSI Crusher/Sand Making

PLS Vertical Shaft Impact Crusher/VSI Crusher/Sand Making MachineMax Feed Size: 3060 mmProcessing Capacity: 16715 TPHOutput Size: 05 mmApplied Materials:The mobile impact crusher MOBIREX MR 110i EVO2 can be universally deployed and produces firstclass final grain quality With a crusher inlet of 1100 mm and numerous technical highlights, a formidable production rate can be achieved with the best cost effectiveness Thanks to its compact design, the machine is easy to transport and can be MR 110i EVO2 Mobile impact crushers The mobile impact crusher MOBIREX MR 130 EVO2 can be deployed universally as an allrounder and produces first class final product quality With a crusher inlet width of 1300 mm, it achieves a production rate that until now was only associated with considerably larger crushing plant This is made possible by outstanding cost effectiveness and MR 130 EVO2 Mobile impact crushers

Vibrating Grizzly Feeders McLanahan

The main purpose of a Vibrating Grizzly Feeder is to feed a primary crusher in a primary application Vibrating Grizzly Feeders reduce the amount of material going into the crusher by scalping out the product size ahead of the crusher Model: Fullstar90, Production capacity: 120180 Tons Per Hour, 2nd crusher: Secondary Impact Crusher, Maximum feeding size: 600 mm, :crushersscreeningplants in Niger