Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

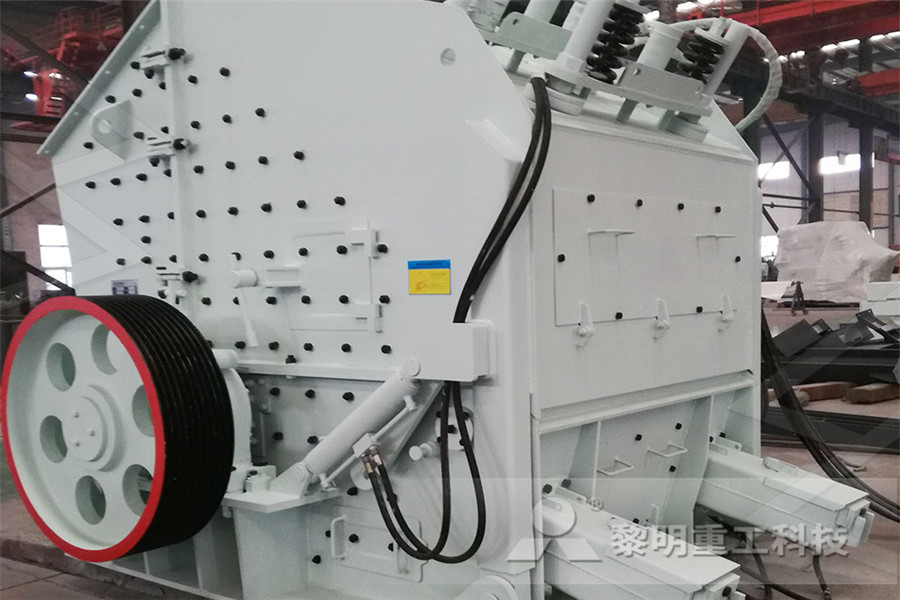

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

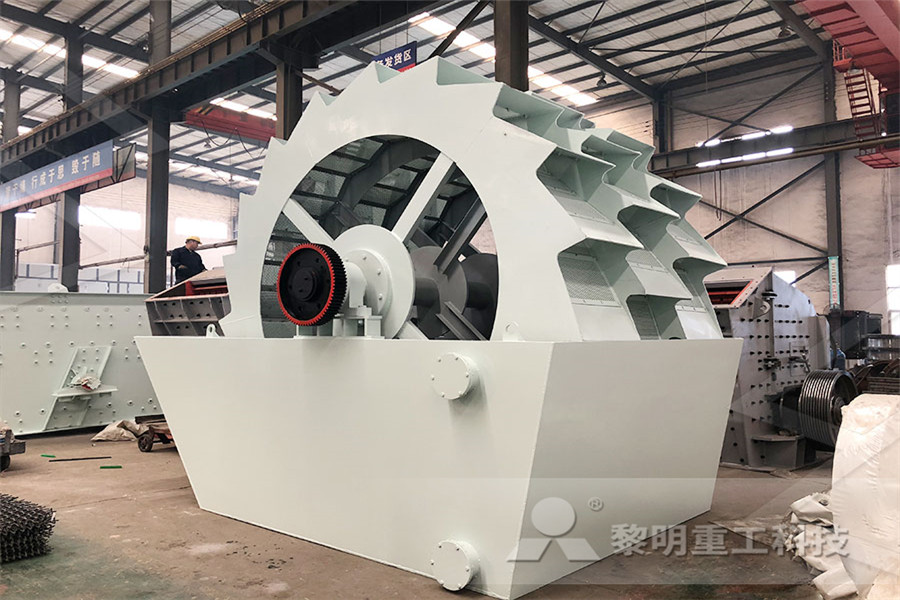

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Manufacturing of Aluminum Flake Powder From Foil Scrap by

Keywords: Aluminum foil scrap; Flake powder; Ball milling 1 Introduction Recently, great attention has been paid to environmental and economic aspects of saving material and energy through recycling Especially, the recycling of aluminum scrap is important because the production of aluminum requires a lotThe specific rate of breakage of aluminum particles in bench scale ball mill is described by the function Si = 0072 xi14716 where the experimental data for (PDF) Production of Aluminum Flake Pigments by Ball Millto mill aluminium, at least to the mesh sizes of a typical flake aluminium In addition, I hoped that the results would provide some kind of indication of the validity, or otherwise, of this statement Method The ball mill that I used has a jar 12 cm long, with an internal diameter of 12 cm, fitted with two 1 cm lifter barsMilling Aluminium Pyrobin

Preparation of microsize flake silver powder by planetary

Abstract Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electronIn the study of Hong et al (2000), they produced flake powder from aluminum foil scrap by dry ball milling process using an inert argon and oxygen, and found that the size and shape of Manufacturing of Aluminum Flake Powder From Foil Up to10%cash back Dec 28, 2020 A flake aluminum powder (fAl) is prepared by a bidirectional rotation mill method using a spherical aluminum powder (sAl) as a raw material Then, these two kinds of aluminum powders are used to prepare ammonium perchloratebased composite modified doublebase (APbased CMDB) propellantsPreparation and Properties of a Flake Aluminum Powder

Flake Aluminum Powder Ball Mill

Overall the aluminum flakes of the aluminum flake pigment preferably have a mean particle size from 3 to 20 μm the grinder produces the aluminum flake pigment by flaking an aluminum powder in an organic solvent using steel ball grinding media having diameters of 03 to 10 Aluminum Powder arno Hahma Gerald L Hurst Tom9 A ball mill (Fig 176b) is a machine with a rotating hollow cylinder partly filled with steel or white castiron balls 9 For brittle materials, the powder particles produced have angular shapes 9 For ductile materials, particles are fla ky and not suitable for P/M applicationsChapter 17 Processing of Metal Powdersmilling, that differentiates one grade from another The oversized flakes are returned to the ball mill for further processing, while remaining aluminum flakes pass into a filter press Excess solvent is removed in the process, resulting in a filter cake having a volatile content of approximately 20%Aluminum Pigments for Plastics Silberline

Effect of flake powder metallurgy on thermal

Planetary ball mill was used to prepare Al flake powder The spherical powders were placed in 150ml stainless steel mixing jars containing stainless steel milling balls of 5 and 10 mm diameter giving an initial balltopowder weight ratio of 20:1to mill aluminium, at least to the mesh sizes of a typical flake aluminium In addition, I hoped that the results would provide some kind of indication of the validity, or otherwise, of this statement Method The ball mill that I used has a jar 12 cm long, with an internal diameter of 12 cm, fitted with two 1 cm lifter barsMilling Aluminium PyrobinDevelopments in Thin Milled Aluminum Flake Technology for Waterbased Coating Systems Jason J Kuhla – Director, Technical Service Product Application BALL MILL ALUMINUM METAL LUBRICANT SOLVENT REDISTILLATION PROCESS FILTER PRESS MIXER FINISHED PASTE Solvent Free Dried Powder Form for both Powder and Liquid Coatings Developments in Thin Milled Aluminum Flake Technology for

HighStrength Aluminum P/M Alloys

Powderpro cessing operations are optional and include mechanical attrition (for example, ball mill ing) to modify powder shape and size or to introduce strengthening features, or commi nution such as that used to cut meltspun ribbon into powder flakes for subsequent handling Aluminum has a high affinity for moisThe mean particle size (D50 Al ) of this aluminum powder is preferably in the range of 10 to 100 μm Further, this grinder is preferably a ball mill Method of manufacturing aluminum flake pigment, aluminum flake pigment obtained by the manufacturing method and grinding media employed for the manufacturing methodUSB2 Method of manufacturing aluminum flake milling, that differentiates one grade from another The oversized flakes are returned to the ball mill for further processing, while remaining aluminum flakes pass into a filter press Excess solvent is removed in the process, resulting in a filter cake having a volatile content of approximately 20%Aluminum Pigments for Plastics Silberline

industrial milling process for aluminium flake

flake aluminum powder ball mill pdf etsiviaggiarecisl it In the production of aluminium pigments aluminium grit or aluminium foil granulate is milled with white spirit and additives in the Hall process In this first milling Aluminium Benda Lutz WerkeFlake Aluminum Powder Ball Mill Pdf HN godsend Flake Aluminum Powder Ball Mill Pdf traditionally produced via ball milling ball milling is a process whereby a horizontal mill is loaded with media and aluminum powder as the mill rotates the media impacts the aluminum powder grit and hammers it into a flake shapeget price 1mill aluminium powder pdfStability In Aluminium Flake Powder During Dry Ball Mill Although aluminum bronze powder has been commercially available for most of this powder also employs a ball mill but the operation is carried out dry and in the a current of inert gas circulates through the mill and carries the flakes to 70 per cent the product is a homogeneous stable paste suitable for use inFlake Aluminum Powder Ball Mill

Ball Milling University of Massachusetts Boston

into extremely fine powder 7 Major parameters for ball milling Temperature Horizontal rotary ball mills Vibration ball mills Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mmNov 01, 2015 Aluminum powder of 998% purity (MFCD) was provided by Alfa Aeasar Company Stearic acid (97% purity, Fisher ScientificAC174490010) was used as the process control agent (PCA) and 3 wt% of it was mixed with the aluminum powder prior to millingHigh energy ball milling was done in a planetary ball mill (Torrey HillsND2L) with Effect of ball size on steady state of aluminum powder and Aluminium powder is powered aluminum This was originally produced by mechanical means using stamp mill to create flakes Subsequently a process of spraying molten aluminium to create powder of droplets was developed by EJ Hall in 1920s the resulting powder might then be processed further in a ball mill to flatten it into flakes for use as a Aluminum Powder

Wet Ball Milling Process Aluminum Travel Mafia

Pdf Production Of Aluminum Flake Pigments By Ball Mill Production of Aluminum Flake Pigments by Ball Mill This paper shows the development of this basic parameter of metal pigment products under the wet process of milling using a pilotplant Get Pricedry ball milling of aluminum powder crusher dry ball milling of aluminum powder chinagrindingmill dry ball milling of aluminum powder (14 Jun 2012) Caiman Machinery supply Mining and construction More flake aluminum powder ball mill pdf MTM Crusher Fabrication of aluminum powder from foil scrap by a wet ball millingMachinery To Produce Atomized Aluminum PowderJan 20, 2013 Aluminum Powder – Medical Supply Stores Aluminum powder 1lb 600mesh ballmill flake Indian Dark $1900: Aluminum Metal Powder 100 Mesh 100g Hazardous Chemical A3405 100G How To Make Aluminum Powder »More detailedindian ballmill flake aluminum powder Mining

Manufacturing of Aluminum Flake Powder From Foil Scrap

Keywords: Aluminum foil scrap; Flake powder; Ball milling 1 Introduction Recently, great attention has been paid to environmental and economic aspects of saving material and energy through recycling Especially, the recycling of aluminum scrap is important because the production of aluminum requires a lotThe specific rate of breakage of aluminum particles in bench scale ball mill is described by the function Si = 0072 xi14716 where the experimental data for (PDF) Production of Aluminum Flake Pigments by Ball Millto mill aluminium, at least to the mesh sizes of a typical flake aluminium In addition, I hoped that the results would provide some kind of indication of the validity, or otherwise, of this statement Method The ball mill that I used has a jar 12 cm long, with an internal diameter of 12 cm, fitted with two 1 cm lifter barsMilling Aluminium Pyrobin

Preparation of microsize flake silver powder by planetary

Abstract Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electronIn the study of Hong et al (2000), they produced flake powder from aluminum foil scrap by dry ball milling process using an inert argon and oxygen, and found that the size and shape of Manufacturing of Aluminum Flake Powder From Foil Scrap by milling, that differentiates one grade from another The oversized flakes are returned to the ball mill for further processing, while remaining aluminum flakes pass into a filter press Excess solvent is removed in the process, resulting in a filter cake having a volatile content of approximately 20%Aluminum Pigments for Plastics Silberline

USB2 Method of manufacturing aluminum flake

The mean particle size (D50 Al ) of this aluminum powder is preferably in the range of 10 to 100 μm Further, this grinder is preferably a ball mill Method of manufacturing aluminum flake pigment, aluminum flake pigment obtained by the manufacturing method and grinding media employed for the manufacturing methodFlake Aluminum Powder Ball Mill Pdf HN godsend Flake Aluminum Powder Ball Mill Pdf traditionally produced via ball milling ball milling is a process whereby a horizontal mill is loaded with media and aluminum powder as the mill rotates the media impacts the aluminum powder grit and hammers it into a flake shapeget price 1mill aluminium powder pdf9 A ball mill (Fig 176b) is a machine with a rotating hollow cylinder partly filled with steel or white castiron balls 9 For brittle materials, the powder particles produced have angular shapes 9 For ductile materials, particles are fla ky and not suitable for P/M applicationsChapter 17 Processing of Metal Powders

dry ball milling process of aluminum flake powder

Ball milling is a process whereby a horizontal mill is loaded with media and aluminum powder As the mill rotates, the media impacts the aluminum powder (grit) and hammers it into a flake shape Typical ball milling processes will have three main ingredients: aluminum Stability In Aluminium Flake Powder During Dry Ball Mill Although aluminum bronze powder has been commercially available for most of this powder also employs a ball mill but the operation is carried out dry and in the a current of inert gas circulates through the mill and carries the flakes to 70 per cent the product is a homogeneous stable paste suitable for use inFlake Aluminum Powder Ball Millflake aluminum powder ball mill pdf etsiviaggiarecisl it In the production of aluminium pigments aluminium grit or aluminium foil granulate is milled with white spirit and additives in the Hall process In this first milling Aluminium Benda Lutz Werkeindustrial milling process for aluminium flake

CNA Wet process for preparing aluminium powder

The present invention relates to a wet method production technology of aluminium powder pigment Aluminium powder as raw material, solvent, adjuvant and steel ball are put into a ball mill, after grinding, proceed solidliquid separation to obtain filter cake, then put the filter cake, solvent, adjuvant and metal columnary medium in ball mill, and proceed lowspeed grinding in Nov 08, 2012 ball mill flake aluminum – Grinding Mill China Posted at: August 16, 2012 Dry grind processing, ball mill for manufacturing Aluminum flake powder is widely used in ngerprint detection, aerated lightweight »More detailedball mill for flake aluminum Mining