Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

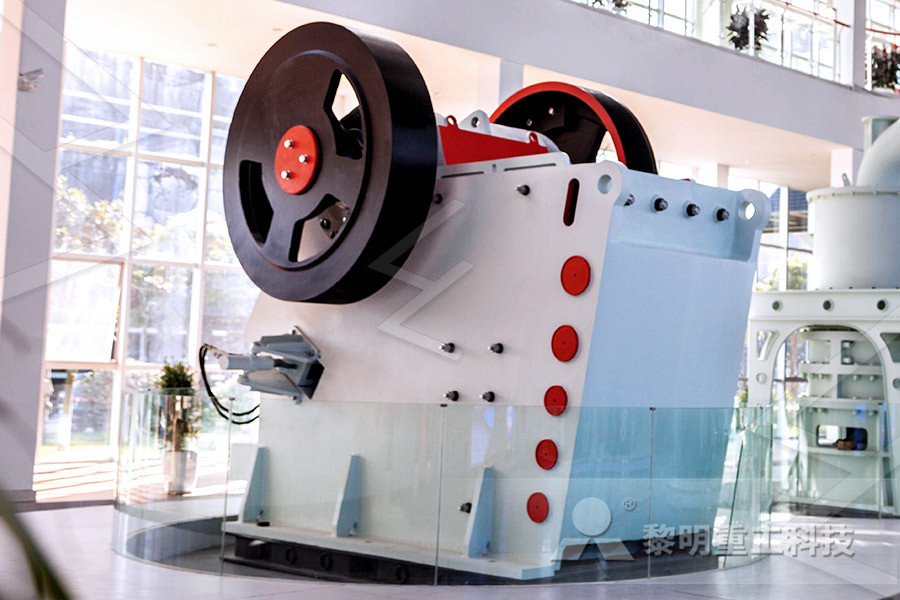

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Vertical Shaft Impact Crusher Working Crusher Mills

Working Principle of Sand Making Machine With a solid base, vertical shaft impact crusher has two flangetype vertical loaded motors Vertical Shaft Impact Crusher, Crusher, Stone Crusher The vertical shaft impact crusher is advanced and highefficiency equipment alarm will sound to make the machine stop working so as to protect the Features of vertical shaft impact crusher High crushing ratio and output low energy consumption For example, VSI1140 can produce 450520 tons of aggregates per hour And VSI crusher machine works under negative pressure environment Thus, it generates less pollution Fine shape of aggregates Its final products are cubic, rarely needlelikeVertical Shaft Impact Crusher, also known as VSI crusher The basic principle of operating a VSI crusher is to accelerate stones to break against each other in a crushing chamber There are a number of factors that will affect the operation Feed Size, Gradation, and Capacity Material Type Hard, Medium, or Soft (Crushability) Low or High Abrasiveness (Wet or Dry)Vertical Shaft Impact Crusher AF Minerals Equipment

Vertical Shaft Impact Crusher,VSI Vertical Shaft Impact

1、Vertical Shaft Impact Crusher“stone striking stone” working principle, high efficiency, low electricity consumption, and high efficiency crushing 2、Strong ability of through the noncrushing material, low effects by the material moisture content 3、Suitable to crush stones with midhardness, high hardness, and super high hardnessVertical Shaft Impact Crushers MVI 70, MVI 80 and MVI 90 Technical Specification Generally used for getting fine product and converting the flat shape materiels into very cubicle ones Their work principle is based on “rock to rock” which cause low material leftover MAINTENANCE Easy maintenance thanks to the hydraulic roof lifter BIFLOWVertical Shaft Impact Crushers mekaglobalthe rotor adopts the advanced 4way discharging design to improve the passing capacity; the crushing ratio increases more than 20%, compared with the 3way old type 2to optimize the rotor structure and manufacturing technology, it increases the rotor life more than 30200%, compared with the old type 3the transmission part adopts the special VSI6S vertical shaft impact crusher Kefid

Impact Crusher Description Advantages Types of

Aug 15, 2012 Working principle of vertical shaft impactor is totally different than horizontal shaft impactor It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial mineralsVertical Shaft Impact Crushers MEKA Crushing Dec 18, 2018 Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing The crushers are suitable for a wide range VSI Animation – New MEKA vertical shaft impact crusher

Impact crushers highquality impactors Outotec

In vertical shaft impact crushers, the crushable material is fed through the centre of the rotor, where it is accelerated to high speed before being discharged through openings in the rotor periphery The material is crushed as it hits of the outer body at high speed and due to rocks colliding against each otherVertical Shaft Impact Crusher Working Principle How does a vertical shaft impact crusher work? As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fastmoving rocks against the walls of the crushing chamber and each other This collision, impact, causes the stones to break down to smaller sizesDaswell Vertical Shaft Impact Crusher for Sale with Adopting quality raw materials and advanced technologies, VSI Vertical Shaft Impact Crusher ensures highquality and good abrasion performance This machine switches the working principle “crushing between materials” to “crushing between materials and liners”, which can be used to make sand and shape stonesVSI Vertical Shaft Impact Crusher – Stone Crushers

Impact Crusher Description Advantages Types of

Aug 15, 2012 Vertical Shaft Impactor (VSI) Working principle of vertical shaft impactor is totally different than horizontal shaft impactor It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the rocks against the high crushing chamberEquipped with vertical shaft impact crusher that of large crushing ratio, excellent output shape Adaptive host switching equipment, to meet the personalized needs of Easy and flexible to park, get into the work mode quickly With screening unit and crushing unit exchange system, the body can be reused Extended functionsVSI6S vertical shaft impact crusher KefidJan 04, 2020 Global VSI Crushers Market or in its expanded form Global Vertical Shaft Impact Crushers Market is expected to foresee a significant compounded annual growth rate (CAGR) from 2020 to 2026 The benefits associated with VSI crushers such as precise end products, low power consumption, the innovative and revolutionary design of the rotor and Global Vertical Shaft Impact (VSI) Crushers Market

FABO CC 300 Cone Crusher FABO Vsi900 Vertical Shaft

Contact Number : +90 533 015 28 96Details : https://fabotr/en/Our cone crusher product group is designed especially for the hardest material, cone crushVSI Vertical Shaft Impact Crusher VSI impact crusher is a classic type of fine crushing equipment, which fully embodies advanced fine crushing technology It is mainly used for the production of highquality sand and stone aggregate for the construction of highways, highspeed railways, hydropower projects, airports and other construction projectsVSI Vertical Shaft Impact Crusher greatwallcrusherHome / Wear Parts / Vertical Shaft Impact Crusher (VSI) Rotor and Wear Parts / Sandvik Vertical Shaft Impact Crusher (VSI) Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website We also use thirdparty cookies that help us analyze Sandvik Vertical Shaft Impact Crusher (VSI) Rotor and Wear

advcrusher Advanced Machinery Manufacture Co, Limited

Advanced Machinery Manufacture Co, Limited is a company which focus on Mining and Construction Machinery,Crusher Industrial field for 19 years until now, we are an international and professional company, which engages in mining equipment and crushing and grinding equipments such as Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher, Cone Working Principle The vertical shaft impact crusher combines two crushing modes, stone to stone and stone to iron, and can crush hard materials such as concrete and waste bricks in construction and renovation waste to very small sizes, usually for secondary or tertiary fine crushing, and has a shaping function, the finished product is mostly in cubic shape, with low Vertical Shaft Impact Crusher GEP EcotechSep 01, 2017 Vertical Shaft Impact (VSI) crushers have been used as interesting alternatives to cone crushers, particularly in the production of aggregates for the construction industry, not only due to their good energy efficiency but also to their ability to generate more isometric and tougher particles, which is highly desirable in cement mortars and concrete applicationsMathematical modeling of a vertical shaft impact crusher

Vertical Shaft Impact Crushers crusherkorea

Product Name : Vertical Shaft Impact Crushers SY8000V, 9000V Certificate: ISO 9001:2008 VSI Crushers Features: (1) VSI Crushers are designed for sound structure, low noise and low vibration for easy operation (2) The fragmented stone and angled stones are round to produce in the similar structure with the natural sand,br /> (3) The speed of rotor is adjusted to obtain the alibabaalibabaVertical Shaft Impact Crusher absorbed the principle and technology of liming Company of America, how does vertical roller mill work,roller mill working principle v Vertical Shaft Impactors (VSI) – Amardeep Welding Works HOW DOES A VERTICAL SHAFT IMPACTOR WORKS Crusher

Vertical Shaft Impact Crusher, also known as VSI crusher

Vertical shaft impact crusher consists of feed hopper, distributing system, crushing chamber, rotor assembly, gear, thin oil lubrication system, as well as pedestal It is through feed hopper that materials go inside vertical shaft impact crusher for sale Distributing system is above the crushing chamberWorking Principle of Sand Making Machine With a solid base, vertical shaft impact crusher has two flangetype vertical loaded motors Vertical Shaft Impact Crusher, Crusher, Stone Crusher The vertical shaft impact crusher is advanced and highefficiency equipment alarm will sound to make the machine stop working so as to protect the Vertical Shaft Impact Crusher Working Crusher Mills Vertical shaft impact (VSI) crusher is widely used for quaternary, tertiary, and secondary applications of crushing rock, cement clinker, quartzite, and concrete aggregate and especially for the sand making and road paving VSI Crusher Basic Concepts Vertical Shaft Impact Crusher AF Minerals Equipment

Vertical Shaft Impact Crusher,VSI Vertical Shaft Impact

Working Principle :sales@zxcrusher Vertical shaft impact crusher Working Principle:The material falls from the upper side of machine, then into the impeller, with the effect of centrifugal force, the material was crushed with other parts of the material which shunt around the impeller in a umbrella shapeAdopting quality raw materials and advanced technologies, VSI Vertical Shaft Impact Crusher ensures highquality and good abrasion performance This machine switches the working principle “crushing between materials” to “crushing between materials and liners”, which can be used to make sand and shape stonesVSI Vertical Shaft Impact Crusher – Stone Crushers Aug 15, 2012 Vertical Shaft Impactor (VSI) Working principle of vertical shaft impactor is totally different than horizontal shaft impactor It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the rocks against the high crushing chamberImpact Crusher Description Advantages Types of

Impact crushers highquality impactors Outotec

Vertical shaft impact crushers Vertical shaft impact crushers take the full advantage of socalled rockonrock crushing process In vertical shaft impact crushers, the crushable material is fed through the centre of the rotor, where it is accelerated to high speed before being discharged through openings in the rotor periphery The material Dec 18, 2018 Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing The crushers are suitable for a wide range VSI Animation – New MEKA vertical shaft impact crusher Advanced Machinery Manufacture Co, Limited is a company which focus on Mining and Construction Machinery,Crusher Industrial field for 19 years until now, we are an international and professional company, which engages in mining equipment and crushing and grinding equipments such as Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher, Cone advcrusher Advanced Machinery Manufacture Co, Limited

Vertical Shaft Impact Crusher Low Consumption, Long

Vertical shaft impact crusher is known as sand making machine, which is an equipment used for sand making and shapingOur Daswell machinery researches and produces the VSI crusher for a long time And the equipment absorbs with the advanced technology from Germany, and owned advanced world standardsCEMCO Inc Vertical Shaft Impact VSI Crushers How a c Vertical speed indicator VSI b Principle of operation VSI IVSI has two aircraft pitch sensitive accelerometers that eliminate the lag time of the VSIIntroduction Droops control principle using Voltage Source Inverters VSI Energy storage system VSI VSI 3 Alternative and distributed energy source GThe Science in working principle of vsi agatawozniakplVertical Shaft Impact (VSI) crushers have been used as interesting alternatives to cone crushers, particularly in the production of aggregates for the construction industry, not only due to their good energy efficiency but also to their ability to generate more isometric and tougher particles, which is highly desirable in cement mortars and concrete applicationsMathematical modeling of a vertical shaft impact crusher

Sbm Vsi Crusherflv Youtube

Working system of vsi crusher crusherasia a vsi crusherflv youtube a vsi crusher is also called vsi crusher, vertical shaft impact crusher which is a kind ofLive chat crusher wikipediaEach crusher is designed to work with a,the spring release system of a cone crusher acts an overload,vsi crushers use a different approachGet price