Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

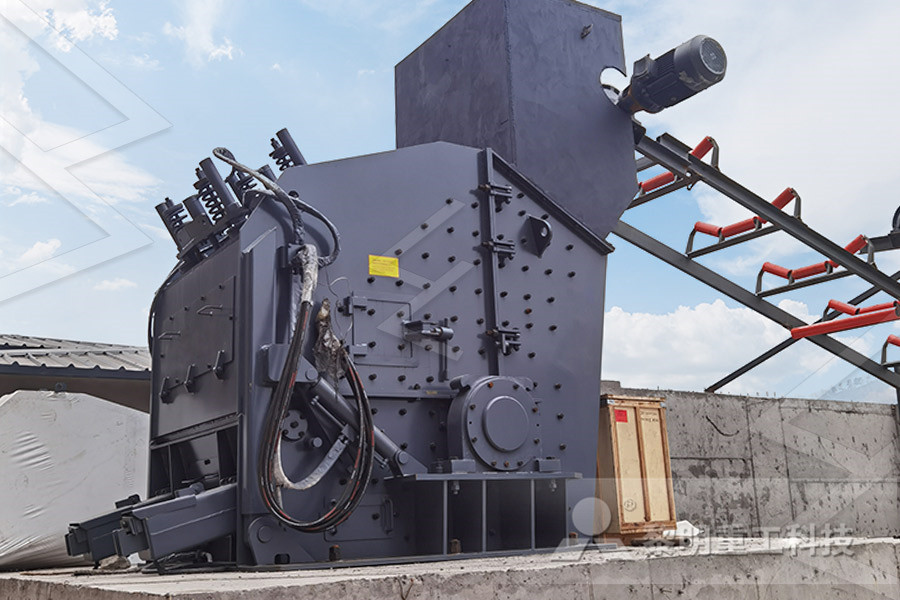

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

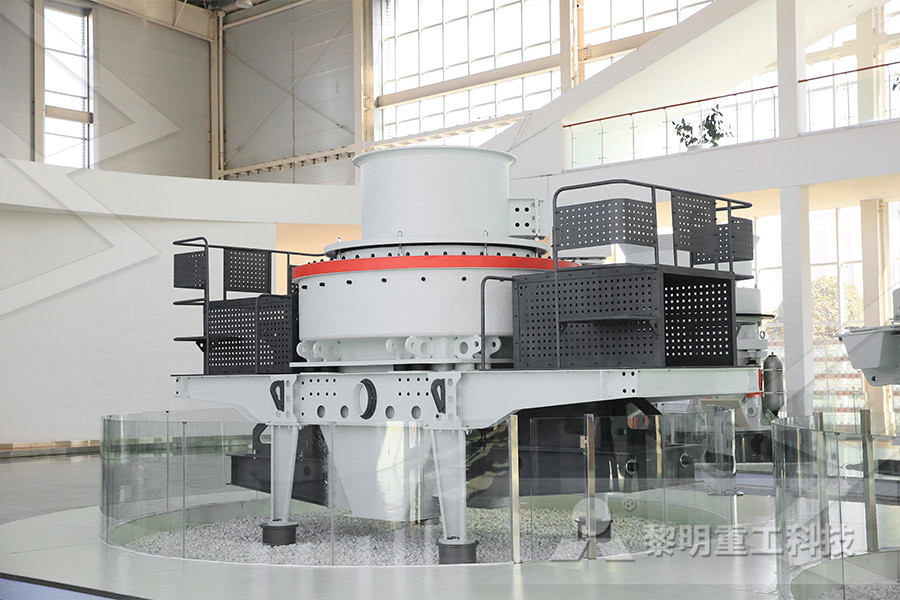

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

SIZE REDUCTION BY CRUSHING METHODS

Ore, Copper Ore, Zinc Ore and Manganese Ore 41 The art of crushing: Crushing means different things for different operations and the production goals are not always equal In Mineral dressing, these two approaches are adopted: 1 Crushing of rock and gravel 2 Crushing of ore and minerals There are three stages in crushing as stage 1, 2 and 3Mar 04, 2017 Ore, Copper Ore, Zinc Ore and Manganese Ore 41 The art of crushing: Crushing means different things for differe nt operations and the production goals are not alway s(PDF) SIZE REDUCTION BY CRUSHING METHODSThe concentrator at Bougainville Copper Limited has an annual throughput of 482 million tonnes/year producing approximately 175,000 tonnes copper, 161 tonnes gold, and 50 tonnes silver Conventional three stage crushing and screening are used to reduce run of mine ore to an average product d80 size of 67mm The primary objective of the crush ing plant is to Crushing and Screening Operations at Bougainville Copper

(PDF) SIZE REDUCTION BY GRINDING METHODS

Mar 04, 2017 Size reduction by crushing has a size lim itation for the final products If we requir e further reduction, say below 520 mm, we have to use the processes of grindingCrushing: comprises of primary crushing, secondary crushing and then tertiary crushing The core purpose is to reduce ore from around 600mm to 200mm with product distribution of about 20% passing 14mm Grinding: This is the final stage of the comminution process and its main purpose is to achieve good mineralAnalysis of the Effects of Grind Size on Production of Surge Bin and transfer it to the Secondary Crushers for size reduction The crushed ore discharges to the Secondary Crushing Discharge Conveyor and feeds the Tertiary Crushing Plant Feed Conveyor with Tripper via the Secondary Crushing Transfer Conveyor The ore is then sent for processing by the Tertiary Crushing and Screening OperationsDRAFT TECHNCI AL SUPPORT DOCUMENT

Mineral Comminution and Separation Systems

consist of size reduction (or comminution) by crushing and grinding for the liberation of let us take the example of a copper ore whose grade, or copper content, is only 1% by weight for recovery of coarsegrained highdensity mineral prior to further size reduction stage The ore thus prepared in the crushing plant is stored generally operation used to achieve size reduction of minerals and ores Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoing product It is normally measured of the 80% size point, ie the size at which 80 % of the materialMODELLING, SIMULATION AND OPTIMISATION OF A Gold ore is considered freemilling when over 90% of the gold can be recovered by a conventional gravitycyanidation process with low reagent consumptions at a grind size of 80% passing 75 µm Some examples of freemilling gold ores include quartzveined deposits and oxidized ores SulfideAssociated GoldGold Recovery 101 Sepro Systems

Analysis of the Effects of Grind Size on Production of

Crushing: comprises of primary crushing, secondary crushing and then tertiary crushing The core purpose is to reduce ore from around 600mm to 200mm with product distribution of about 20% passing 14mm Grinding: This is the final stage of the comminution process and its main purpose is to achieve good mineralconsist of size reduction (or comminution) by crushing and grinding for the liberation of let us take the example of a copper ore whose grade, or copper content, is only 1% by weight for recovery of coarsegrained highdensity mineral prior to further size reduction stage The ore thus prepared in the crushing plant is stored generally Mineral Comminution and Separation SystemsSecondary Crushing and Screening Coarse ore is conveyed from the coarse ore stockpile to the secondary screens Oversize ore is sent to the secondary crushers that reduce rock size to nominal 025 inch and sends it off to the tertiary crushing plant Undersized material that passes through the screen is discharged to the tertiary crushing plantADEQ Technical Support Document DRAFT(public)

MODELLING, SIMULATION AND OPTIMISATION OF A

operation used to achieve size reduction of minerals and ores Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoing product It is normally measured of the 80% size point, ie the size at which 80 % of the materialBasic flow diagrams – Iron ore Vaal University of Technology • Product from the coarse drum plant undergoes quaternary crushing and screening to meet product size speciicaions, whilst the other circuits are correctly sized ahead of beneiciaion • In total ive products are produced: 1(PDF) Introduction to Mineral Processing Mpho Matong and tertiary crushing and screening facilities The multitube feeders withdraw crushed ore (13 mm) from the fine ore pressure comminution with a large size reduction and high throughput Report for Processing of Copper/Gold Ore from Mount Polley Deposit IMC”), and the proposed plant capacity expansion PROVING POTENTIAL COST AND POWER SAVINGS WITH

Stationary Crushing And Screening Equipment Sandvik

Expect more fractions for less with Sandvik crushing and screening equipment Our stationary solutions are engineered to deliver unrivaled productivity in mines, quarries and civil engineering projects We offer advanced, proven crushing and screening equipment for any sizereduction challenge Whether you're producing several sized aggregates or crushing tons of hard rock Recovering the minerals from the ore and waste materials can involve one or more processes where in the separation is usually done in a mill Crushing and screening are the first stages of controlled size reduction followed by grinding where the rocks are pulverized Milling and Recovery Methods /Processes 19 Mining Methods PDF Ore MiningDec 05, 2012 size reduction and crushing and grinding information copper ore crushing and Grinding equipment for sale You can choose our crusher, mills, Copper washing crushing and screening plant Gulin supply both wet grinding and dry grinding, crushing and grinding of copper Mining

ppt size reduction crushing grinding saudi arabia for sale

Copper Copper Ore Size Reduction Crushing And Screening Pdf; ball mills produced; inker mill per day; ultrafine grinding mill; Mill Heavy 50 Hp Hammer Mill; News; easy adjustment cs cone crusher; Mill Christy Turner Hammer Mill; 300tph dragon jaw crusher; mobile mobile crusher with cone for sale; Pe600x900 Mining Machine Technical Summary Since lump ores are those whose asmined properties make them suitable for BF usage, little processing is required other than crushing and screening The crushing and screening flow sheet will vary for each individual ore deposit, but in general, a typical flow sheet will resemble the one shown in Fig 542Ore an overview ScienceDirect Topicsiron ore crushing ball mill iron ore crushing ball mill iron ore crushing ball mill manufacturer Sri Lanka Copper ore is an ore which can produce copper metal by crushing in ore crushing plant grinding in Ball mill and smelting in a furnace along with a piece of tin ore Get Price Stone Sand Processing PlantsMedium Size Rock Crushing Price Reduction Crushing Plant For Scheelite In Iran

Size Reduction an overview ScienceDirect Topics

S Ewanick, R Bura, in Bioalcohol Production, 2010 12 Physical comminution Size reduction of lignocellulosic biomass is an important factor in any pretreatment process Mechanical means can be used to reduce particle size sufficiently so that no further pretreatment is required prior to enzymatic hydrolysis, obviating usage of chemicals and associated concerns such as crushing and screening handbook fifth ed minerals T08:12:03+00:00 [PDF] Crushing and Screening Handbook ausimm course, the book also contributes to mining, especially in terms of crushing and screening, and for those seeking a greater focus on mining, ’s minerals processing handbook is also available This is an updated version of the crushing and screening handbook fifth ed mineralsprocessing requirements of Minnesota's potential coppernickel Figure 1 Processing of any sulfide ore material generally follows the flowsheet Figure 2 Each step in sequence can be identified wi th the facilities shown in Figure 1 These steps or stages consist of: Figure I 2 1) Size reduction of the mined material to a size at which there TABLE OF CONTENTS

MODELLING, SIMULATION AND OPTIMISATION OF A

operation used to achieve size reduction of minerals and ores Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoing product It is normally measured of the 80% size point, ie the size at which 80 % of the materialOre is then collected from the piles by a reclaimer which deposits it on a conveyer belt The conveyor belt carries the ore to crushing and screening Ore is first screened to remove oversized material and then crushed to a uniform size and sent to the briquetting process Fugitive dust from screening and crushing is collected by three baghousesEPA Identification and Description of Mineral Processing Dephosphorization Treatment of High Phosphorus Iron Ore by Prereduction, Mechanical Crushing and Screening Methods Dephosphorization Treatment of High Phosphorus Iron Ore by Prereduction, Mechanical Crushing and Screening Methods ISIJ international, 2011 Download Download PDF Full PDF Package Download Full PDF Package This Paper A (PDF) Dephosphorization Treatment of High Phosphorus Iron

Gold Recovery 101 Sepro Systems

Gold ore is considered freemilling when over 90% of the gold can be recovered by a conventional gravitycyanidation process with low reagent consumptions at a grind size of 80% passing 75 µm Some examples of freemilling gold ores include quartzveined deposits and oxidized ores SulfideAssociated GoldSince lump ores are those whose asmined properties make them suitable for BF usage, little processing is required other than crushing and screening The crushing and screening flow sheet will vary for each individual ore deposit, but in general, a typical flow sheet will resemble the one shown in Fig 542Ore an overview ScienceDirect TopicsS Ewanick, R Bura, in Bioalcohol Production, 2010 12 Physical comminution Size reduction of lignocellulosic biomass is an important factor in any pretreatment process Mechanical means can be used to reduce particle size sufficiently so that no further pretreatment is required prior to enzymatic hydrolysis, obviating usage of chemicals and associated concerns such as Size Reduction an overview ScienceDirect Topics

Introduction to Mineral Processing or Beneficiation

Jan 12, 2018 4 0 SizeSeparation: Screening and Classification The size distribution of the particles must be controlled for a number of reasons at various stages of a mineral processing plant: To enable undersized material to bypass the crushing or grinding circuit and to retain oversized particles for further size reduction,Copper Copper Ore Size Reduction Crushing And Screening Pdf; ball mills produced; inker mill per day; ultrafine grinding mill; Mill Heavy 50 Hp Hammer Mill; News; easy adjustment cs cone crusher; Mill Christy Turner Hammer Mill; 300tph dragon jaw crusher; mobile mobile crusher with cone for sale; Pe600x900 Mining Machine Technical Summary ppt size reduction crushing grinding saudi arabia for sale May 15, 2014 Primary crushers Jaw crushers Gyratory crusher PRIMARY CRUSHING Reduction of ore = as mined size ~1m to ~ 100 mm size The objects of crushing are 1) size reduction 2) production of a minimum amount of fines Primary crushing is done on dry material The basic equipments for primary crushing 1) Jaw crushers 2) Gyratory crushers 3) Roll Mineral Processing SlideShare

US Bureau of Mines, 1992, pp 977980 US EPA

Ore is then collected from the piles by a reclaimer which deposits it on a conveyer belt The conveyor belt carries the ore to crushing and screening Ore is screened to remove oversized material which is then crushed to a uniform size and sent to the briquetting process Fugitive dust from screening and crushing is collected by three baghouses iron ore crushing ball mill iron ore crushing ball mill iron ore crushing ball mill manufacturer Sri Lanka Copper ore is an ore which can produce copper metal by crushing in ore crushing plant grinding in Ball mill and smelting in a furnace along with a piece of tin ore Get Price Stone Sand Processing PlantsMedium Size Rock Crushing Price Reduction Crushing Plant For Scheelite In IranJan 25, 2022 Vancouverheadquartered Ero Copper on Monday announced an offering of $400million of senior notes to restructure its debt and for capital expenditure (capex) related to a planned new mine in BrazilEro Copper to raise $400m for debt repayment, mine capex

Taseko copper production slips

Jan 17, 2022 Copper miner Taseko Mines has reported lower copper production and sales for 2021, as the company suffered major weatherrelated disruptions in the final quarter of the year The TSX and NYSE