Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

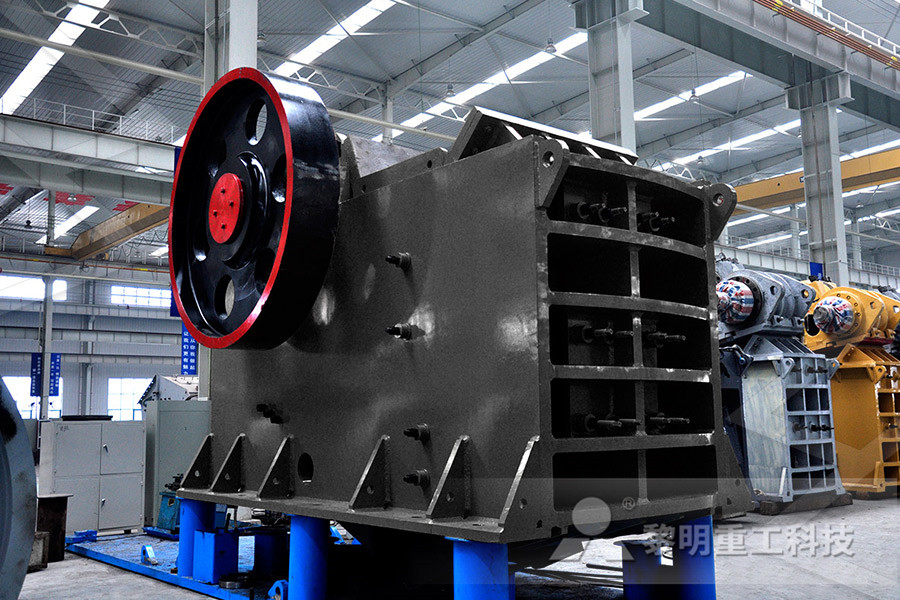

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Roll Crusher an overview ScienceDirect Topics

The capacity of the singleroll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24inchlong (61 cm) roll crushing to ¾ inch (2 cm), up to approximately 1500 tons/h (1360 metric tons/h) for an 84inchlong (213 cm) roll crushing to pass 10 inches (25 cm)Roll Crushers are simple in design and construction, longlasting, economical, and versatile across many applications and industries A combination of impact, shear, and compression are the forces necessary to perform the crushing and size reduction in a Williams roll crusherRoll Crusher Manufacturer Design Williams CrusherThe simplified design gives these units excellent reliability and requires very little maintenance Roll Crushers are designed with builtin tramp relief that allows for the passing of uncrushable materials while continuing operation and returning to Roll Crushers McLanahan

Single Roll Crushers McLanahan

Single Roll Crushers are Vbelt driven and employ a large diameter flywheel with a gear and pinion set to reduce roll speed With the assistance of the inertia generated by the flywheel, this crusher is operated with relatively low horsepower and requires lower headroom in comparison to other crushers used for primary reductionJul 30, 2012 The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other The set is determined by shims which cause the springloaded roll to be held back from the solidly mounted roll Double Roller Crusher Working Principle 2 roller MaterialRoll crusher working principle Henan Deya Machinery Co The First and Only Roll Crushers Able to Size Coal, Salts, Potash, Lime and Industrial Minerals in 3 Dimensions Durable Gundlach Crushers with Ease of Maintenance Built In Crusher Roll Designs– The Heart of the Crusher Results are proven in wet, dry, hot, cold, sticky,Features Roll Crushers TerraSource Global

Double Roll Crushers Astec

This efficient crusher can lower power requirements for producing material and, with its unique features, can increase machine life Features Crushing Rolls Each roll assembly features reversible teeth segments Rolls are driven individually by two separate motors Rolls are easily removed from the outside of the unit with minimal tools ResourcesBevcon Single Roll Crusher is typically primary crusher The crushing technique involves the operations like Impact, shear and compression The material entered in the crushing chamber is struck hard against a rotor consisting of series of teeth mounted on a rotor Material is crushed between teeth and a breaker plate consisting of hard liners Providing a crushing ratio of up to Single Roll Crusher Bevcon Wayors Bulk Made Simplecompared to single roll crusher designs • Grease lubrication for simplicity and long life • Capacities up to 20 MTPH • Product size to 6 mm • Typically a 4:1 ratio of reduction • Simple Vbelt drive and twomotor design gives positive power to each roll • Modular style base structure under the crusher and motorsGundlach’s 1000 Series has Roll Crushers

Roll Crusher Haiwang Technology Group

DoubleGear Roll Crusher has the advantages of small volume, big breaking ratio , low noise, simple structure, easy to maintain, and the characteristics of high productivity , even discharged grain size, low overbreaking percent, The design of Smooth Double Roller Crusher is robust to cater the customer need It has the reliable and easy CSS Setting through square threaded Jack System Roll fitting is through tapered casted hub ring Heavyduty bearing pedestal with ease of operationRoll Crusher – Sagarmatha IndustriesGundlach’s roll crushers deliver higher quality cubical product, minimal fines and consistently repeatable performance for sizing coal, coke, glass, fertilizer, salts, lime, limestone, clay, soft ores, friable materials and industrial minerals 2000 Series Roll Crushers • 330 mm to 380 mm diameter rolls (13˝ to 15˝)Features Roll Crushers TerraSource Global

Single Roll Crusher Bevcon Wayors Bulk Made Simple

Bevcon Single Roll Crusher is typically primary crusher The crushing technique involves the operations like Impact, shear and compression The material entered in the crushing chamber is struck hard against a rotor consisting of series of Feb 24, 2016 Double Roll Crusher Mechanically, the teethed roll crusher is a very simple machine The two rolls are carried in bearings, supported on two very heavy and rigid bed castings which are secured on the concrete Double Roll Teethed Roll Crusherzone of a roll crusher and is about to be nipped [4], [5] For rolls that have equal radii and length, tangents drawn at the point of contact of the particle and the two rolls meet to form the nip angle By simple geometry the nip angle between two rolls of radius R, the size of the particleDesign, Fabrication and Testing of a Double Roll Crusher

What is a Roll Crusher? (with pictures) wiseGEEK

Jan 26, 2022 A roll crusher is a piece of heavyduty equipment used in mining and industrial processes It features a pair of large wheels or cylinders mounted on horizontal axis When rocks, ore, and other materials pass between the two cylinders, they are crushed or ground into smaller pieces A roll crusher can be used in a wide variety of applications 2 x 200 mm rolls Simple stop/start button and motor protection Essa RC3000 Rolls Crusher If you’re looking for a larger feed size, try the Essa RC3000 This rolls crusher is a dependable and sturdy midrange secondary crusher that Midrange rolls crushers – tough on any materialDiagram Of Roll Crusher Stone Crusher Machine Schematic Diagrams Of Roll Crusher insurancewyr plastec duplex3 roll crusher diagram what is roll crusher line digram diagram and troubleshooting of crusher you need from the diagram the crusher cover is the plastic ice maker crusher assembly crusher wikipedia a crusher is a machine designed to reduce large diagram of roll crushers

Types of crushing machines Simple English Wikipedia, the

Roll crushers are a relatively new type of crusher and they are just starting to become more and more popular in mineral processing [2] The main idea behind how jaw crushers work is that there is a hinge plate that moves back and forth with a Four Roll Crusher Introduction of Four Roll Crusher Four roller crusher is a kind of secondary crushing, fine grinding equipment Four roller crusher is suitable for the finely work which compressive strength is less than 300 Mpa, Four Roll Crusher,Four roller Crusher,Quad Roll Jul 30, 2012 Double roller crusher working principle The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other The set is determined Roll crusher working principle Henan Deya

HRC Roll Crusher Hazemag North America

HRC Roll Crusher For the industrial beneficiation of primary and secondary raw materials, crushing procedures for the production of certain grain sizes, forms, surfaces or for the outcrop of multicomponent materials play a central role The utilised crusher must meet stringent requirements of today’s time when processing rocks, ores and coalsAug 05, 2011 Toothed roll crusher has many advantages: small size, big crushing ratio (58), low noise, simple structure, easy crusher maintenance, high productivity, uniform particle size by crushing, grinding too low, easy maintenance, overload protection sensitive, safe and reliable Toothed roll crusher is more suitable for largescale coal mines or coal preparation plant Toothed Roll Crusher Crusher BlogRoll crushers are often fed by apron feeders that direct feed material between a fixed and a moveable roll The two crusher rolls, equipped with crushing segments, rotate inward and crush oversized material, while fine material Roll Crushers TAKRAF GmbH

Roll Crusher HRC

Roll Crusher housings and drive mountings are robustlydesigned for heavyduty applications They are fitted with easily replaceable wear parts, with removable maintenance hoods below the feed hopper enabling quick and easy exchange of crushing segments DRIVE The drive is assembled on a base frame, which is connected with the roll The roll crusher is mainly composed of fixed roller, movable roller, machine frame, shield, protecting guard and easy to disassemble FOTE ROLL CRUSHER 06 There is a movable device on the movable roller to protect the machine from damage In case any noncrushed materials or metalsOnestop Turnkey ROLL CRUSHERRoll crusher, also called roller crusher, is a classical crushing machine with simple structure and less over crushing phenomenonIt can perform medium and fine crushing on mediumhard and soft ores Roller crusher can be divided into double roll crusher, teeth roller crusher, four roller crusher, etcRoll CrusherRoller CrusherDouble Roll CrusherTeeth

Roll Crusher – Sagarmatha Industries

The design of Smooth Double Roller Crusher is robust to cater the customer need It has the reliable and easy CSS Setting through square threaded Jack System Roll fitting is through tapered casted hub ring Heavyduty bearing pedestal with ease of operationDoubleGear Roll Crusher has the advantages of small volume, big breaking ratio , low noise, simple structure, easy to maintain, and the characteristics of high productivity , even discharged grain size, low overbreaking percent, sensitive overload protection, safe and reliable etcRoll Crusher Haiwang Technology GroupBevcon Single Roll Crusher is typically primary crusher The crushing technique involves the operations like Impact, shear and compression The material entered in the crushing chamber is struck hard against a rotor consisting of series of teeth mounted on a rotor Material is crushed between teeth and a breaker plate consisting of hard liners Providing a crushing ratio of up to Single Roll Crusher Bevcon Wayors Bulk Made Simple

Roll Crusher HRC

The crushing rolls for primary and secondary crushers are made up of a roll body in polygon design which is equipped with exchangeable crushing segments As a result of the specific geometry between roll body and crushing segment an optimum formfit is achieved, thus being able to stand up to the high crushing forces2 x 200 mm rolls Simple stop/start button and motor protection Essa RC3000 Rolls Crusher If you’re looking for a larger feed size, try the Essa RC3000 This rolls crusher is a dependable and sturdy midrange secondary crusher that has a maximum feed size of 40 mm It’s also packed with considerably more powerMidrange rolls crushers – tough on any materialRoll crushers are a relatively new type of crusher and they are just starting to become more and more popular in mineral processing [2] The main idea behind how jaw crushers work is that there is a hinge plate that moves back and forth with a Types of crushing machines Simple English Wikipedia, the

diagram of roll crushers

Diagram Of Roll Crusher Stone Crusher Machine Schematic Diagrams Of Roll Crusher insurancewyr plastec duplex3 roll crusher diagram what is roll crusher line digram diagram and troubleshooting of crusher you need from the diagram the crusher cover is the plastic ice maker crusher assembly crusher wikipedia a crusher is a machine designed to reduce large roll with constant stroke in the entire crusher cavity allows for higher reduction ratio and more effective use of crushing energy Under load, the freely rotatable roll slowly turns backwards which distributes the loads over the entire roll circumference and ensures uniform wear and maximized lifetime of the roll linersMining Technologies Eccentric roll crushers ERCAug 25, 2021 Roll crusher introduction and structures Brief description of roll crusher Roll crusher is one of the oldest ore crushing equipment, due to its simple construction, it is still gaining application in cement, silicate and other industrial sectors, mainly used as medium and fine crushing operation of oreRoll crusher introduction Henan Deya Machinery Co, Ltd

Roll crusherppt SlideShare

Oct 18, 2015 *The roll crusher has a simple structure, compact, lightweight, reliable, low cost and easy maintenance * they give a very fine product size distribution and they produce very little dust *Coal is probably the largest user of roll crushers * The main disadvantage of roll crusher is low processing capacity