Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

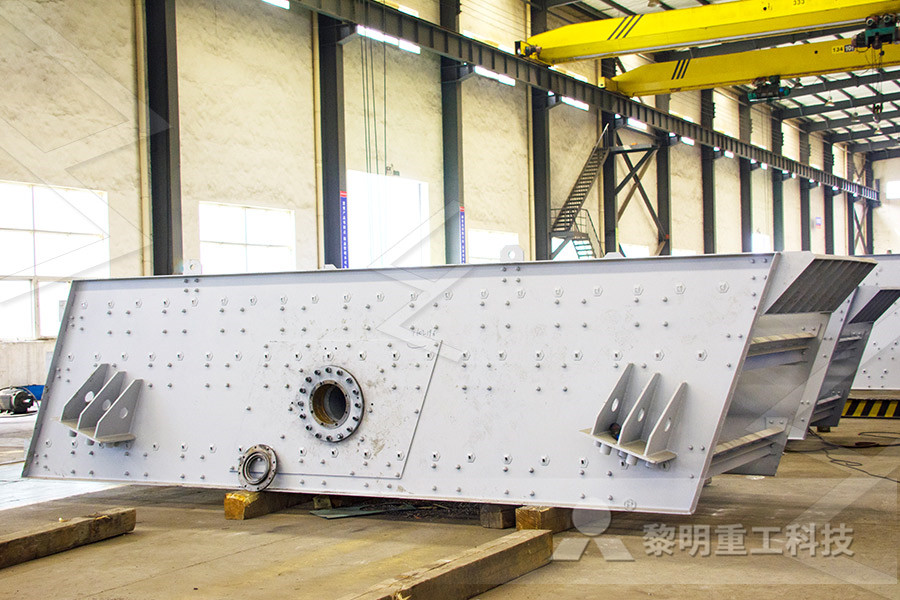

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mills an overview ScienceDirect Topics

Generally, filling the mill by balls must not exceed 30%–35% of its volume The productivity of ball mills depends on the drum diameter and the relation of ∫ drum diameter and length The optimum ratio between length L and diameter D, L: D, is usually accepted in the range 156–164Feb 13, 2017 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volumeBall Mills Mineral Processing MetallurgyBenchtop ball mills are ideal for wet or dry grinding applications requiring the highest degree of fineness Shop RETSCH Models PM 100 and PM 200 Planetary Ball Mills Fisher Scientific Display: Color Graphic Display: Dimensions (L x W x H) 165 x 249 x 185 in (4191 x 6324 x 4699cm) View More SpecsRETSCH Models PM 100 and PM 200 Planetary Ball Mills

Vertical Square Planetary Ball Mill (Production Model

Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for RD institution, university, enterprises laboratory to get samples (each experiment can get four samples at the same time) It gets powder samples under the vacuum state when equipped with vacuum ball mill tankIf a ball mill contained only coarse particles, then 100% of the mill grinding volume and power draw would be applied to the grinding of coarse particles In reality, the mill always contains fines: these fines are present in the ball mill feed and are produced as MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLINGShop a large selection of Mills products and learn more about RETSCHModels PM 100 and PM 200 Planetary Ball Mills Two grinding stations Benchtop ball mills are ideal for wet or dry grinding applications requiring the highest degree of fineness Graphic display and onebutton operation for setting speed, time, energy input, grinding RETSCHModels PM 100 and PM 200 Planetary Ball Mills

MIRL Mill Simulator

“Propagation delay” means the delay in output of ball mill 1 step delay is equal to 1 second So if a user opts for larger step delay, the output of ball mill will take longer to display “Appearance Function” relates to the retention of material in the ball mill In the ideal situation, there will be no retention of material in the ball millVQN ball mills may be referred to as shaker mills, mixer mills or highenergy ball mills They can be used for both wet and dry grinding as well as to mix a variety of solids, suspended liquids and pastes This unit is ideal for preparing small batches of your sample efficientlySample Mill at Thomas ScientificBall Milling Particle Size Ball mills steel ball mills lined ball mills particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800 s the basic construction of a ball mill is a cylindrical container with journals at its axis moresmall sizes ball mill ideal for display

Ball Mill Grinding Media Options Orbis Machinery, LLC

Apr 26, 2019 Glass ball mills are ideal for grinding of pigments in mills vertically and also horizontally Glass ball mills are particularly suited for applications in mills because of their specific mass which can process low and medium viscosity mill bases The glass beads, that is, the glass ball meals are thermally and chemically treated to maintain In video, we have explained working of our newly constructed laboratory ball mill of 2kg mill jar It comes with stainless steel grinding jars and balls It Laboratory Ball Mill 2 KG with Digital RPM Display cum 2Ideal for wet or dry grinding application 3Automatic and programmable control with LED display 4Multiple grinding modes to choose 5High uniformity and excellent repeatability 6Fast rotational speed, high efficiency and fine granularity 7Programmable interval and pause times 8Four samples with different sizes and materials in one Planetary Ball Mill cysiwang

Planetary Ball Mill BM 1200+

This planetary ball mill model owns small volume and high efficiency, low noise and functional features which is an ideal equipment for RD institution, university, enterprises laboratory to get samples (each experiment can get four samples at the same time)These ball mills pulverize and mix soft, mediumhard, and extremely hard as well as brittle and fibrous materialsDesigned for rapid, highspeed grinding of small samples, these mills utilize stainless steel or hardfaced blades to successfully pulverize even the most difficult materials These blades either pulse or provide continuous operation depending on the specific samplesPlanetary Ball Mills, Retsch® VWRBALL MILL DRIVES, LOADED, WAVEFORM LEVELS, SEPTEMBER 1A 1B • Above is a plot of the waveform vibration levels at both the 1A 1B ball mills when loaded (acceleration) • Note how waveform levels at 1A ball mill are higher than that at 1B ball mill for every measurement and especially at points PIH PIA (pillow block, couplingend bearing)BALL MILL GEARBOX PROBLEM Vibration

Chishun Planetory Ball Mill Plasma Sources and

Chishun Planetory Ball Mill PM series planetary ball mill is an essential device for mixing, fine grinding, sample preparation, nanomaterials dispersion, new product development and small batch production of hightech materials With small size, fullfeature, high efficiency and low noise, this product is an ideal instrument for scientific Vertical Planetary Ball Mill YLK Vertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production It can mill the materials from 3~10mm maximum into 01µm minimum powder, This model owns small volume, high efficiency, low noise and functional Vertical Planetary Ball MillLaboratory Ball MillsFeatures Comminution with a ball mill Observation of the milling process Ball mills are a form of mills with grinding bodies The drums can be opened at the front and loaded with the material to be milled (limestone is recommended) and the milling balls The drums are mounted on a drive roller and a loose roller with adjustable spacing between the axles At low rotation speeds the Laboratory Ball Mill Model MT 122 Scitech Didactic

Ball Milling University of Massachusetts Boston

Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1)Ball mill is typically used to grind and/or blend materials and it can be done wet or dry It can be used to mix ceramic powders, disperse particles in solvents, homogenize ceramic slurries, etc Ball mills operate by rotating plastic jars around a horizontal axis, partially filled with the material to be ground plus the grinding mediumMilling Ball Milling tablesIdeal for standardization of QuEChERS The BeadBlaster 96 is an extremely versatile ball mill homogenizer that has applications in both research and display and a safety switch stops operation of the unit in the case of an overload Any sample wet, dry or cryogrindFor all your high throughput sample preparation needs

small sizes ball mill ideal for display

Ball Milling Particle Size Ball mills steel ball mills lined ball mills particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800 s the basic construction of a ball mill is a cylindrical container with journals at its axis more2Ideal for wet or dry grinding application 3Automatic and programmable control with LED display 4Multiple grinding modes to choose 5High uniformity and excellent repeatability 6Fast rotational speed, high efficiency and fine granularity 7Programmable interval and pause times 8Four samples with different sizes and materials in one Planetary Ball Mill cysiwang2Ideal for wet or dry grinding application 3Automatic and programmable control with LED display 4Multiple grinding modes to choose 5High uniformity and excellent repeatability 6Fast rotational speed, high efficiency and fine granularity 7Programmable interval and pause times 8Four samples with different sizes and materials in one Planetary Vertical Ball Mill cysiwang

110V Planetary Ball Mill 4X500ml Lubrication Free

PBM2 planetary ball mill is a compact and easytouse laboratory planetary ball mill for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small sample preparing, new product development and small volume hightech material production The systems features small volume, high efficiency, low noise and quick clampCeramic ball mill is the typical grinding equipment which us ball mill ceramics, greatly improves the grinding fineness Compared with the traditional ball mill, such kind of ball mill has a great advantage in function, structure, and operation This machine also has great capacity, high technology, and no noise, which plays an important role Ceramic Ball Mill For Grinding Materials FTM MachineryThese ball mills pulverize and mix soft, mediumhard, and extremely hard as well as brittle and fibrous materialsDesigned for rapid, highspeed grinding of small samples, these mills utilize stainless steel or hardfaced blades to successfully pulverize even the most difficult materials These blades either pulse or provide continuous operation depending on the specific samplesPlanetary Ball Mills, Retsch® VWR

Cryomill the perfect mill for cryogenic grinding RETSCH

The CryoMill is a laboratory ball mill specifically designed for this application The CryoMill's versatility (cryogenic, but also wet and dry grinding at room temperature) makes it the ideal grinder for sample quantities up to 20 ml Powerful impact ball milling results in highest grinding efficiency LEDs in the display indicate the ACEYVPM400ML vertical planetary highenergy ball mill is suitable for rapid, efficient and accurate sample development, mixing and homogenization in the laboratory It is a small grinding equipment with small volume, low noise, strong controllability, comprehensive functions, fine grinding and fast grindingbattery pack assembly line amoybrandIdeal for standardization of QuEChERS The BeadBlaster 96 is an extremely versatile ball mill homogenizer that has applications in both research and display and a safety switch stops operation of the unit in the case of an overload Any sample wet, dry or cryogrindFor all your high throughput sample preparation needs

Grinding Mills Westpro Machinery

BALL MILL Westpro’s Ball Mills ensure fine grinding of minerals and ore Our Ball Mills are engineered to provide the most efficient solution for fine finishing ADVANTAGES Liners are less expensive than Rod Mill steel liners Ideal for fine grinding applications Easy grinding media handling BM58 (5′ Dia x 8′ Lg) Ball Mill fully into the mill as recirculating material; this prevents overgrinding of the finished product in the ball mill discharge Heat generated during the grinding process can be dispersed by good mill ventilation and by injecting water Layout of a ball mill / Industrial Solutions polysius ball mills ThyssenKruppSecond, the working principle of the ball mill In fertilizer production enterprises, ball mills account for more than 80% of the total electricity consumption of the enterprise due to their relatively large power The basic structure of all types of ball mills is roughly the same, except that some of their components are different All are Application of Weirkai Frequency Converter in Ball Mill of

Manual Planetary Ball Mill PM400 University of Washington

Notes on the Operating Manual 8 11 Explanations of the safety warnings In this Operating Manual we give you the following safety warnings Serious injury may result from failing to heed these safety warnings We give youMSKSFM13S is a benchtop high throughput planetary ball mill designed to achieve the most efficient milling and fine grinding quality 4 grinding stations with 4 cavity SS milling jars allow you to prepare up to 16 different materials (alloys, ceramics, chemical products, polymer composites, metal oxides, minerals, etc) in an efficient wayThis is an ideal solution whenever high Benchtop Horizontal Planetary Ball Mill with Four 100ml